Automated Product Validation Systems

For design validation testing

Design Characterization Systems

Endurance / Reliability / Durability / Environmental Testers

Software delivered for over 500 product validation systems

Complete hardware/software package, including fixturing for UUT, delivered for ~200 product validation systems

NI Integration Partner

You’re designing a new product and need to know how it’ll perform under a wide variety of conditions, and potentially over a long duration (in cycles or time).

That’s a lot of data to collect and analyze!

At Viewpoint, we’ve developed software for over 500 product validation systems, and delivered the complete package (both hardware & software) for roughly 200 of these.

See our whitepaper on Design Validation Testing with LabVIEW.

How We Can Help

Turnkey automated product validation system delivery

LabVIEW software development (e.g., test profiles, recipes, sequences; algorithms; logging; GUI)

Automated Measurements (e.g., temperature, pressure, vibration, current, load, voltage, flow, acoustics)

Automated Report Generation

Automated Control

Test Results archiving

Data collection

Equipment control – for spanning voltage levels, temperatures, signal inputs, and so on

Data processing and analysis

Signal conditioning

Environmental chamber control

End-to-end system calibration for measurement traceability

Measurement equipment selection

Automated Product Validation System Case Studies

Custom Automated Test System – Quantifying Energy and Durability Performance for Refrigeration

Custom Automated Test System – Quantifying Energy and Durability Performance for Refrigeration

Automation reduces manual labor while improving traceability

Assessing performance for improved energy ratings and longevity

Client – Zero Zone – Commercial refrigeration systems manufacturer

Challenge

Zero Zone wanted to improve the capabilities and durability of their new reach-in refrigeration products.

You might think that refrigeration is a mundane product line, but that is just not true! So many innovations are occurring as manufacturers are redesigning their products to improve their environmental footprint through better energy efficiency, coolants, and durability.

Assessment requires an understanding of the performance of the refrigeration units under many conditions. Zero Zone was taking measurements with a datalogger with too few channels, and no synchronization, to other devices that feed into the system. Plus, they had multiple models of their reach-in refrigerators that needed to be assessed. Furthermore, simplifying the data collection and analysis would make it easier to validate against ASHRAE standards.

Zero Zone came to Viewpoint with the following high-level desires:

- Expand the measurements by adding more channels and channel types (e.g., 4-20 mA, ±10 VDC and digital I/O).

- Provide graphs and KPIs to enable faster analysis of the data during the test.

- Minimize the chance of data loss during long test runs.

- Synchronize data collection and actuation.

- Automate storage of measurements per a user-defined period to eliminate manual start/stop of data collection.

- Simplify the manual configuration setup.

- Enable a way to find relevant data perhaps months or years after the test run.

Solution

Viewpoint developed a monitoring and control durability test system that could exercise Zero Zone’s refrigerators through hundreds of operation cycles over multiple conditions to simulate actual usage in, for example, a grocery store.

During initial conversations, we collaborated closely with Zero Zone to brainstorm on some potential approaches. We made some suggestions that could satisfy their desires while also managing their time and cost budgets.

For example, by automatically populating the cells in an Excel template based on their original systems’ Excel spreadsheet, we provided streamlined report generation without having to rewrite all the calculation code embedded in their Excel file in another app. The compromises we jointly endorsed were:

- Run an app on a PC to configure and monitor the test.

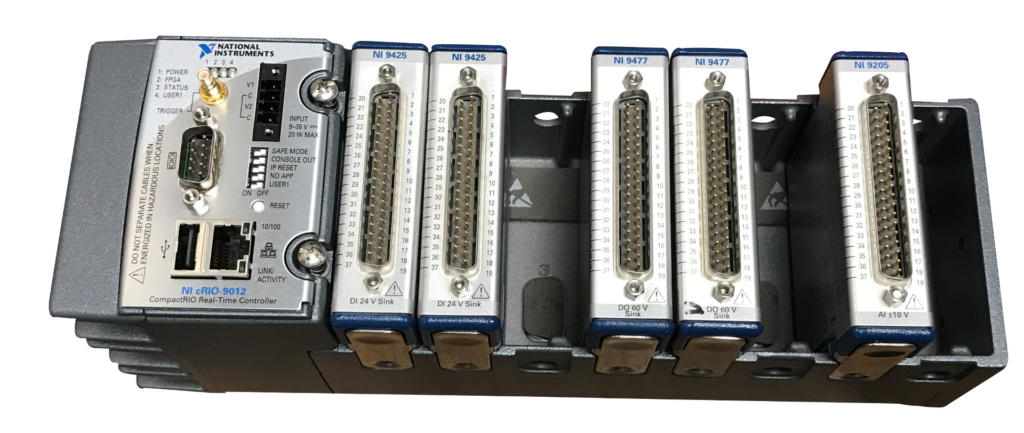

- Use both NI Compact RIO and Compact DAQ to enable robust and synchronized data collection and control with the ability to expand channels by adding modules in both the cRIO and cDAQ chassis.

- Store data on a local PC rather than a remote server to minimize the probability of data lost during the test run.

- Save configurations into Excel files for recall, and cloning, of prior setups.

- Write measurements automatically into the same Excel file for archive of the test setup and measurements.

- Create, in this same Excel file through cell formulas, the summary report from the summary calculations. This approach allowed flexibility for changes to internal and external test standards.

- Upload the summary data and test reference info into a SQL database for data management and long-term test statistics.

Digital outputs (DOs) were used to control various aspects of the test, such as door open/close and defrost on/off cycles. For flexibility, the user can specify the sequencing of these DO channels, in the Excel file used for the test, with various parameters that define the duty cycle, period, number of cycles, and start delay. The timing of these DO state changes was synchronized to the data acquisition by the real-time loop in the cRIO.

This system was deployed to 6 test bays, each one of which might be testing a unit for as little as a few weeks or as much as a few months.

Benefits

The main goal of this project was to reduce the effort and associated human error in the design and execution of the test run.

Some of the primary benefits for this automated system were:

- Reduced Errors: pre-verified template files used for test configuration and data storage lent consistency to test setup and execution.

- Less Testing Time and Effort: the automatic execution of the test and storage of measurements enabled running tests for multiple days (and nights) without technician interaction. Technicians could work on setting up other units for test rather than babysit the existing test. On average, based on the duration of the test time, testing throughput increased by approximately 25% to 40%.

- Shorter Reporting Time and Effort: reports were available about 85% faster than the time previously spent creating manually. The quicker feedback saved costs through early detection of unit problems and faster teardown at the end.

Some additional major benefits were:

- More details on refrigerator operation: “Wow! We never saw that before.”

- Database consolidation: statistical analysis takes hours not days and includes all tests run in the lab, not just ASHRAE tests. This central database enables long term retrieval of all test data.

- Reuse: techs embraced ability to reuse and modify previous setups.

- Consistency: driving the test definition through an Excel file encouraged uniformity.

- Traceability: documented and timestamped calibration measurements.

- Flexibility: channel counts, acquisition modules configuration, calibration, and calculation formulas were straightforward to change for new test setups.

The test automation provided by this system greatly reduced the labor involved in configuring, running, and analyzing the test run. Furthermore, the customer benefited from the consistency that resulted from the software-enforced process.

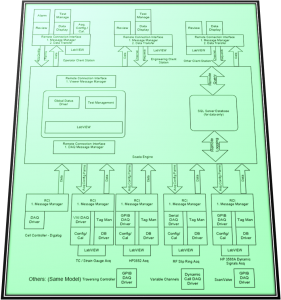

System Overview

We developed the application in LabVIEW and LabVIEW RT combined with a cRIO connected to a cDAQ via TSN Ethernet.

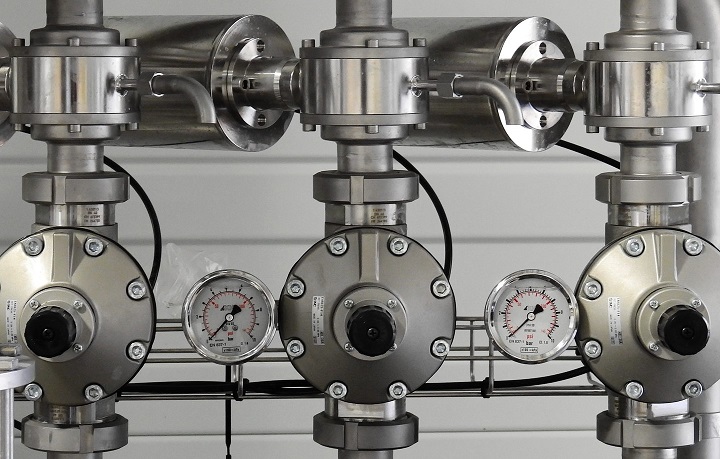

The data acquisition modules slotted into the cRIO and cDAQ chassis handled the I/O to the customer sensors and actuators. The sensors mostly measured:

- temperature,

- pressure,

- flow,

- power, and

- voltage.

| SOFTWARE FUNCTIONS |

|---|

| Data logging of between 50 and 150 channels and control via digital signals |

| Interface with Excel files for configuration, data logging, and summary calculations |

| SQL database for summary and test setup data |

| Real-time loop for robust operation |

| HARDWARE USED |

|---|

| NI cRIO 8-slot chassis, TSN enabled |

| NI cDAQ 8-slot chassis, TSN enabled |

| Various NI cSeries signal conditioning modules |

Custom Automated Test System – Characterization of Heat Transfer System Thermal Performance

Custom Automated Test System – Characterization of Heat Transfer System Thermal Performance

R&D testing required flexibility in control schemes and measurement I/O

Client – ATSI, a large-scale System Engineering Provider

Challenge

Our client, ATSI, Inc., headquartered in Amherst NY, designs and builds complex structures and process systems, from industrial construction projects to mechanical systems for power engineering. A previous, long-standing Viewpoint customer that does research and design of thermal energy systems approached ATSI to engage in the build of a specialized test skid that would be used to assess and characterize a heat transfer system. Our long-standing end-customer requested a data acquisition subsystem based on LabVIEW.

Furthermore, the end-customer requested a subsystem that supported flexibility in the data acquisition by channel count and type, since the R&D nature necessitated adaptability. The overall test system needed to automate progress through a sequence of setpoints and ramps.

Solution

ATSI designed the automated control and sequencing with a Modicon PLC. Viewpoint augmented ATSI’s engineering resources to provide the data acquisition subsystem and setpoint sequence editing. This sequence was passed to the PLC for automated sequencing thought the setpoint list. Because our mutual end-customer did not provide explicit design details, we had flexibility to decide which aspects of the control and data acquisition needs would be automated by the Modicon PLC and which by the PC running LabVIEW.

Since Viewpoint had previously developed a similar application for our end-customer, with some of the required data acquisition needs, we chose to leverage and enhance that software platform for this project. That choice drove some of the other designs and defined the scope of work for Viewpoint and ATSI.

Some overall design decisions were:

- The LabVIEW application provided data acquisition, test configuration, and operator screens.

- The Modicon-based subsystems provided process control and safety.

- A PLC HMI for process system operation and status as well as control loop tuning.

- NI Compact DAQ (cDAQ) offered flexible PC-based acquisition channels for high sample rate historical data collection.

- A sequence editor on the PC defined the test setpoints, durations, and limits to pass to the PLC for execution.

The test configuration encompassed cDAQ channel configuration, PLC tag configuration, sequence editing, and graphical views on the acquired data. Some channels were acquired at slow rates, e.g., up to about 1 S/s for sensors measuring parameters such as temperature and flow, while others had fast rates, e.g., 1 kS/s to 10s of kS/s for sensors measuring parameters such as transient pressure and vibration. Handling the datafile storage and display of this wide range of data types and rates was important for the end-customer to compare and correlate the effects of changing operating conditions.

Data logging is configured by the sequence editor to occur on certain conditions such as immediately entering a new step, time delayed after entering a step, and activated by the PLC upon reaching stable setpoint control. This flexibility gave the end-customer management of when data collection occurred to ease the comparison and correlation of readings from selected sensors.

After the configuration is completed, the sequence is passed to the PLC. The operator starts the test on the PLC HMI and the PLC automates the test run. Data collected during the test run could be displayed in live graphs during testing, used for verification of setup and operation; post-test in stacked graphs and overlaid plots; and exported for specialized analysis, display, and review.

Benefits

The design of this system was driven largely by the need for flexibility. Sensors and channels could be added, the test sequence could be edited with a variable number of steps with editable execution features, and the data acquisition and storage permitted various rates and logging criteria.

These design choices offered the following advantages:

- As a partner of the team, Viewpoint acted as staff augmentation for ATSI by providing experienced engineers with expert LabVIEW and data acquisition capabilities.

- Flexibility of test sequences, including setpoints and their stabilization criteria.

- Tight integration between the Modicon PLC and LabVIEW-based PC enables critical control and safety to execute reliably and yet adjustably.

- Customized mechanical all-welded skid plugs into end-customer’s test article.

- Setup of data logging including configurable sample rates.

- Ability to add channels by plugging in supplemental DAQmx-based cDAQ modules.

- The LabVIEW application architecture is actor-based for straightforward inclusion of new data sources as needed in the future.

- New data sources are registered with the object-based data aggregator.

- The system handles multiple days of test execution

- The multi-pronged viewer allows verification checks while in setup an operation as well as post-test review.

System Overview

The custom automated test system supplied to the end-customer was a hybrid, made up of PC-based and PLC-based components coupled with the fluid-handling components on the skid. The hardware listed below includes only the data acquisition, control, and safety items, and only a high-level description of the mechanical aspects.

| SOFTWARE FUNCTIONS |

|---|

| NI LabVIEW for Windows [Viewpoint] |

| NI LabVIEW Modbus driver [Viewpoint] |

| NI DAQmx hardware drivers [Viewpoint] |

| Actor-based object-oriented LabVIEW application for the PC [Viewpoint] |

| Modicon Concept software [ATSI] |

| Blue Open Studio HMI software [ATSI] |

| Function Block Programming for the PLC [ATSI] |

| HARDWARE USED |

|---|

| Modicon PLC and modules for pressure, temperature, flow and other process variables |

| NI Compact DAQ modules, including 4-20 mA, RTD, thermocouple, thermistor |

| 600 VDC Power supplies |

| Components to flow fluid, including pumps, valves, pressure regulators |

| Intel Tower PC for LabVIEW |

| Mini Industrial PC for HMI |

Replacing Wire-wrap Boards with Software, FPGAs, and Custom Signal Conditioning

Replacing Wire-wrap Boards with Software, FPGAs, and Custom Signal Conditioning

Electronic components of fielded systems were aging out

Reverse engineering effort converted wire wrap boards to FPGA-based I/O

Client – Amentum – A supplier for Military Range System Support

Challenge

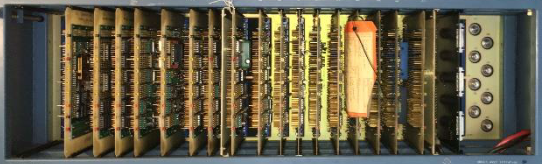

Amentum (www.amentum.com) supports a decades-old system deployed in the early 1980s. While the mechanical subsystems were still functioning, the wire-wrapped discrete logic and analog circuitry was having intermittent problems.

Systems designed and built decades ago can sometimes have wonderful documentation packets. Nevertheless, we’ve been burned too often when the docs don’t incorporate the latest redlines, last-minute changes, or other updates.

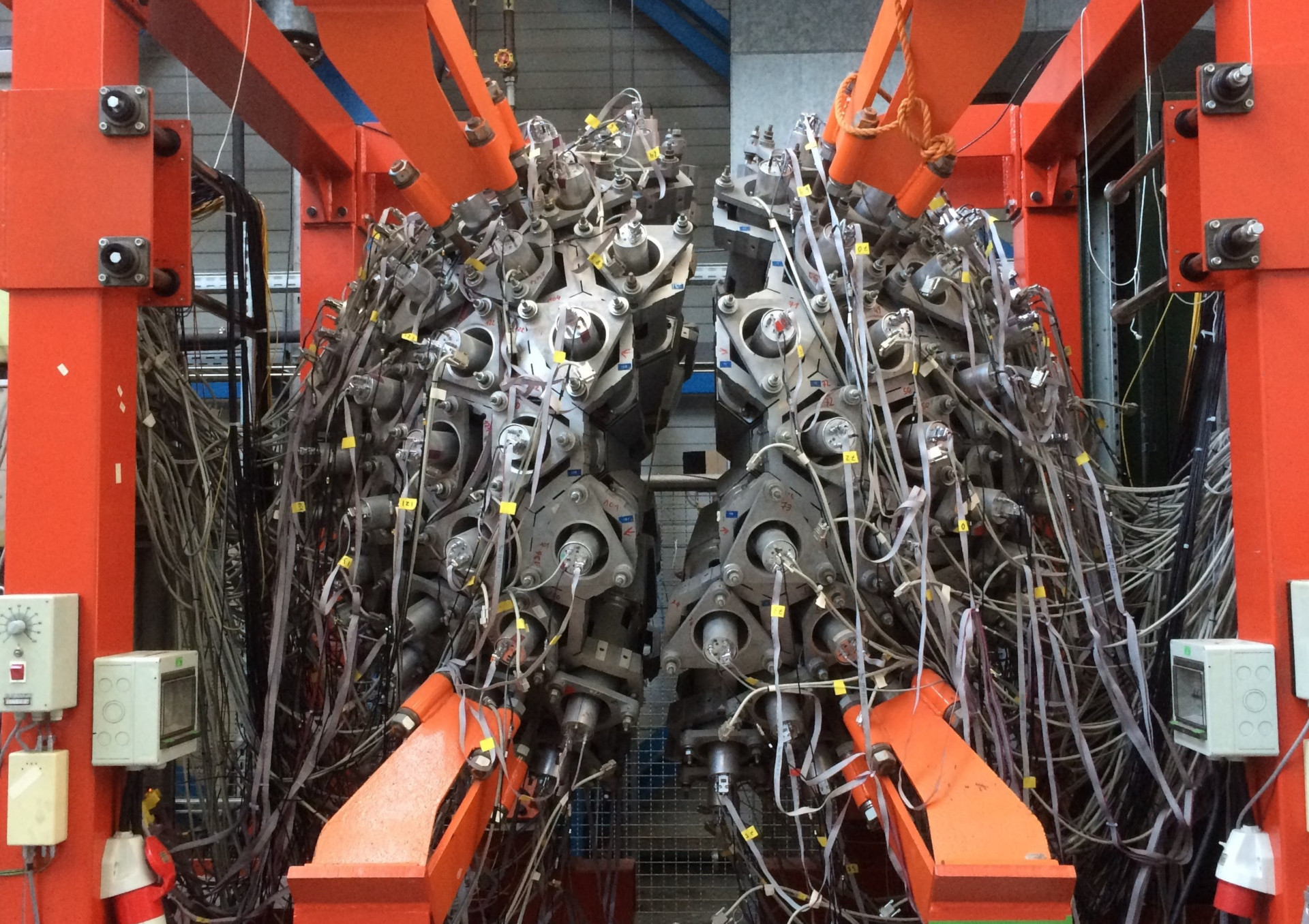

The replacement system needed to be a form-fit-function replacement to land in the same mounting locations as the original equipment with the same behavior and connections. Below is an image of the existing wire-wrap boards and their enclosure. We had to fit the new equipment in this same spot.

Figure 1 – Original wire-wrap boards

Finally, Amentum wanted to work with Viewpoint in a joint development approach. While our joint capabilities looked complementary, we didn’t know at the start how well we would mesh with our technical expertise and work culture – it turns out we worked extremely well together as a team and neither one alone could have easily delivered the solution.

Solution

Since the team treated the existing documentation package with suspicion, we adopted a “trust but verify” approach. We would use the documents to give overall direction, but we would need details from the signals to verify operation.

Leveraging Amentum’s experience with the fielded systems, the team decided early on to record actual signals to understand the real I/O behavior. We used the system’s “test verification” unit to run the system through some check out procedures normally run prior to system usage. This verification unit enabled us to use a logic analyzer for the I/O to and from the discrete logic digital signals and an oscilloscope and DMM for the analog signals. The available schematics were reviewed to assure that the signals made sense.

With a trustable understanding of system operation, Amentum created a requirements document. We jointly worked on the design of the new system. There were both an “inside” system (in a control shelter) and an “outside” system (in the unit’s pedestal).

Some overall tasks were:

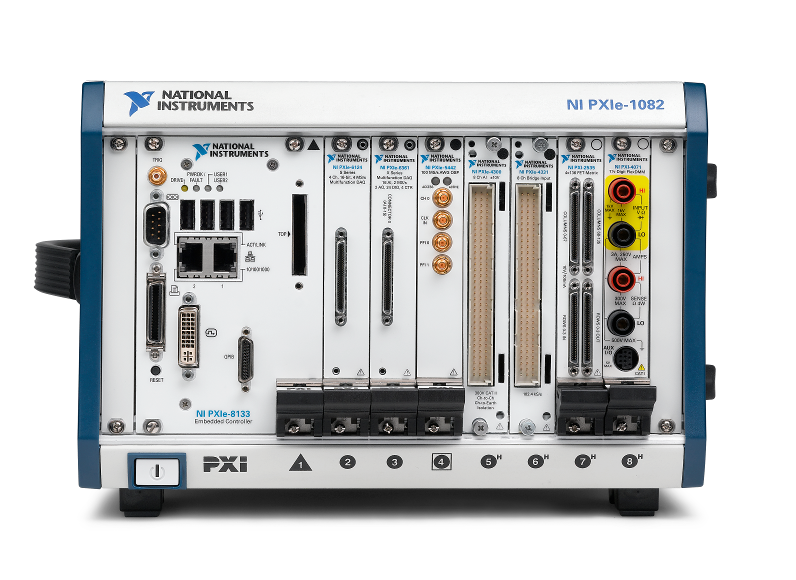

- Viewpoint recommended an architecture for the inside application running on PXIe LabVIEW RT and FPGA layers.

- Amentum created the system control software on a Linux PC.

- Viewpoint developed the more intricate parts of the inside application and mentored Amentum on other parts they developed. This work recreated the existing discrete logic and analog I/O using PXIe NI FPGA boards.

- Viewpoint designed custom interposer boards to connect harnesses to the NI PXIe equipment, including a test point and backplane boards.

- Amentum designed and developed the cRIO-based outside system application and Viewpoint created a set of custom interposer boards to connect harnesses to the cSeries modules.

The PXIe FPGA boards handled the required 60 MHz clock-derived signals with correct phases, polarity, and so on. Furthermore, the wire-wrap boards were register-based so the PXIe had to decode “bus signals” sent over a Thunderbolt bus to emulate the programming and readouts from the various wire-wrap boards.

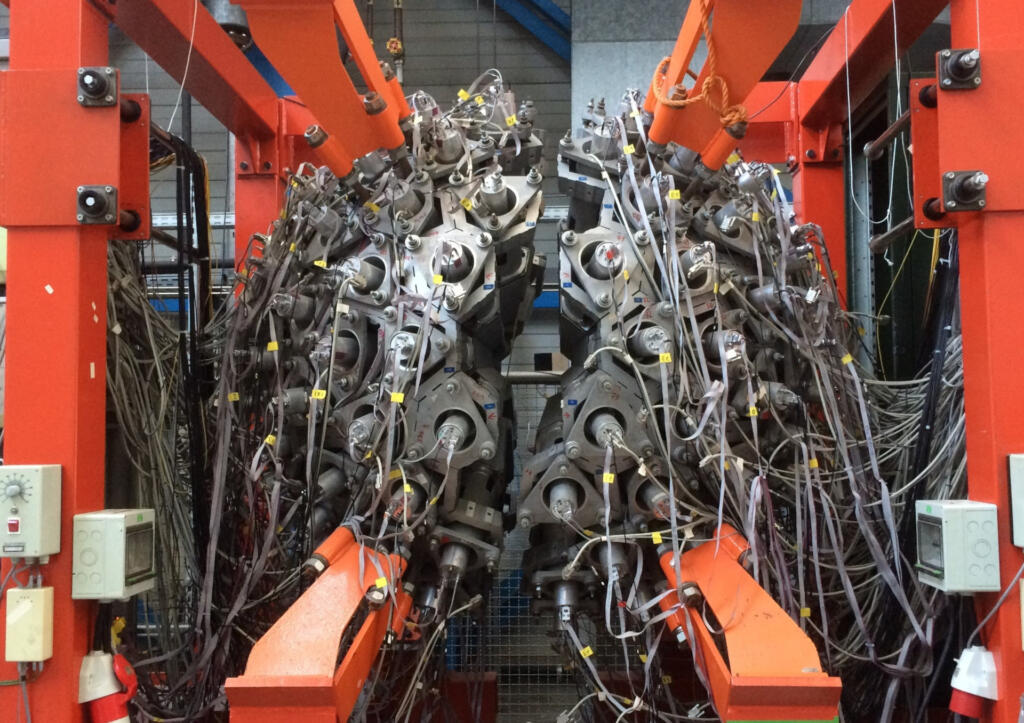

Figure 2 – PXIe replacement to wire-wrap boards

Amentum wanted to be able to support the LabVIEW FPGA VIs used to replace the functionality of the discrete logic. So, Viewpoint acted as mentor and code reviewer with Amentum to ramp them up on using LabVIEW FPGA effectively. Neither one of us alone would have been successful coding the applications in the allotted time. Joint knowledge and experience from both Viewpoint and Amentum were required.

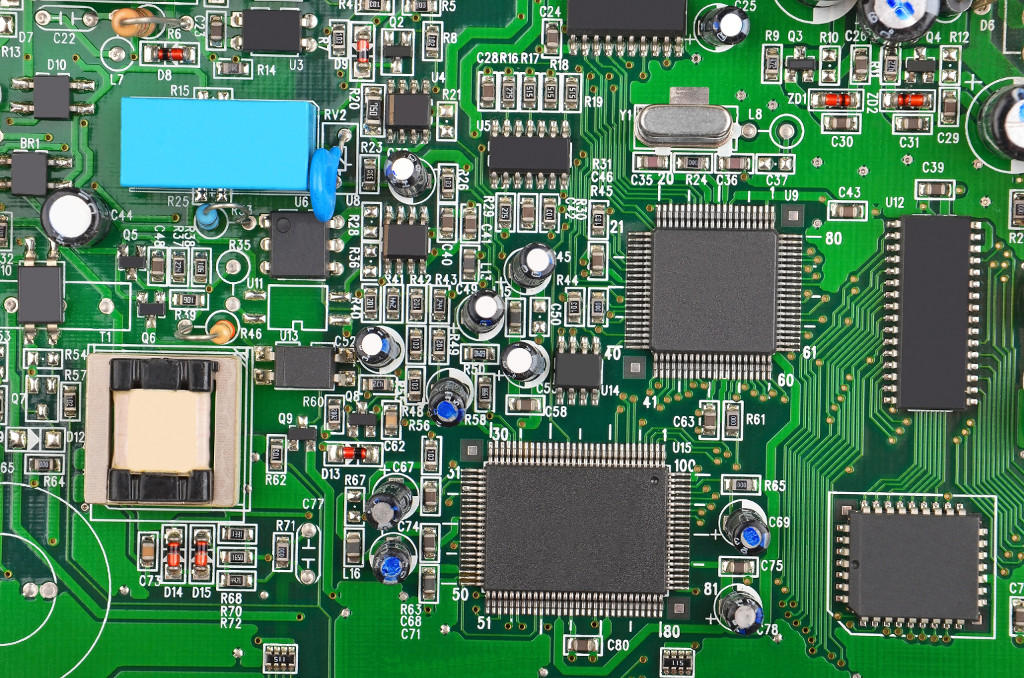

Signal conditioning and harnesses needed to be reworked or replaced as well, of course, since the landing points for the wires were different in the new system. Viewpoint suggested a technique, which we’ve used frequently in past obsolescence upgrade projects, to create PCB boards that accepted existing connectors.

For the cRIO, these interposer “connection” PCBs plugged directly into the cRIO cSeries module. For the PXIe, these interposer PCBs accepted the field wiring connectors and converted them to COTS cables that connected to the PXIe modules. These interposer PCBs could have signal conditioning incorporated as needed. This approach significantly reduced the need for custom harnesses. All told, about 200 signals were passed between the PXIe and various other subsystems, and about 100 for the cRIO. This approach saved significant wiring labor and cost.

Figure 3 – cRIO with interposer boards between cSeries and field harnesses

The work to design and build the signal conditioning custom electronics was split between Viewpoint and Amentum. Viewpoint did more design than build and handed over the schematics and Gerber files to Amentum so they could manage the builds while also being able to make modifications to the boards as needed.

Benefits

Amentum wanted an engineering firm that was willing to work along side them as a partner. Joint discussions about architecture and design led to a collaborative development effort where Amentum benefited from Viewpoint’s extensive expertise and guidance on LabVIEW architectural implementation and FPGA coding style.

The main outcomes were:

- As a partner of the team, Viewpoint acted as staff augmentation by providing experienced engineers with technical capabilities that Amentum initially lacked.

- This team approach delivered a stronger product to the end-customer more quickly than either of us could do alone.

- The combination of Viewpoint’s and Amentum’s experience reduced the amount of reverse engineering needed due to the lack of firm requirements.

- Reduction of electronics obsolescence by using software-centric FPGA-based functionality. Recompiled LabVIEW FPGA could target future boards models.

- Increased software-based functionality simplifies future updates and modifications.

- Decrease in number of parts leading to simpler maintenance.

- Lower wattage consumed eliminated need for an anticipated HVAC upgrade.

- Cybersecurity concerns were reduced by using Linux-based systems and FPGA coding.

System Overview

Using software to emulate the old hardware was a critical success factor. Since the requirements were not 100% solid at the start of the project, some field-testing was required for final verification and validation. The flexibility of the software approach eased modifications and tweaks as development progressed. A hardware-only solution would have necessitated difficult and costly changes. For example, some of the changes occurred very near the final deployment after the system was finally connected to an actual unit in the field.

| SOFTWARE FUNCTIONS |

|---|

| Emulate original discrete logic functions via FPGAs |

| Emulate original analog signal I/O |

| Overall system control via Linux PC |

| Maintain the same user experience as existed before |

| Modern application architecture for simpler maintenance |

| HARDWARE USED |

|---|

| NI cRIO chassis with various cSeries modules |

| NI PXIe chassis with FPGA modules to handle all the analog and digital I/O via a combination of multifunction and digital-only cards |

| Custom PCBs for signal conditioning and connectivity |

Enhanced Portable Data Acquisition and Data Storage System

Enhanced Portable Data Acquisition and Data Storage System

Using a Real-Time Operating System (RTOS) provides a high level of synchronization and determinism for acquired data.

Client

Tier 1 Automotive Design and Manufacturing Supplier

Challenge

Our client had an existing data acquisition system, used for mechanical product validation testing, that had undergone many updates and patches for over 15 years. These updates and patches, performed by multiple developers, had rendered the software portion of the system somewhat unstable. Furthermore, the system hardware was based on NI SCXI, which was becoming obsolete. These issues prompted our client to migrate to an entirely new system.

New requirements for this upgrade included utilizing a PXI controller running NI Linux Real-Time, a RTOS, executing a LabVIEW RT application. The data acquisition software had to support a variable mix of signal conditioning modules in the PXI chassis. In addition, the data acquired from these signal conditioning modules needed to be synchronized within microseconds.

Solution

Viewpoint leveraged another application, developed for the client a few years prior, to harmonize the user interface and to reduce development effort. Most of the development time focused on support and configuration of the multiple module types and ensuring that the data synchronization functioned as required. The result was an ultra-flexible, portable, high-speed data acquisition software/hardware combination that can be used to acquire time-sensitive, synchronized data across multiple modules in a PXI chassis running a real-time operating system.

Benefits

The upgraded system offers the following features:

- Highly configurable real-time data acquisition hardware/software solution based on LabVIEW RT and PXI hardware. Our client works closely with OEMs to assure compatibility and durability with their products, often going to the OEM’s test cells to collect performance data. The configurability in modules and channels affords the fastest possible setup at the OEM’s site which minimizes time and cost in the test cell.

- Configuration files stored in a SQL database format. Saving channel and module setups in SQL allows the test engineer to locate previous hardware and data acquisition configurations. The usual alternative is a bulk save of an entire system setup rather than using a more granular, and hence, more flexible approach afforded by using the database.

- Immediate test feedback through graphs and analog indicators, used to assure data quality before leaving the test cell.

- Data playback features after the data has been acquired, used for in-depth review of data after leaving the test cell.

- Data acquisition on the RTOS provides assurance that the acquisition will not be interrupted by network or other OS activities, which was occasionally an issue with the prior Windows-based application.

- Synchronization between signal conditioning modules ensures time-critical data taken on separate modules can be compared and analyzed.

System Overview

The system consisted of custom LabVIEW RT software intended to run on an engineer’s laptop and the PXI real-time controller and a PXI chassis populated with a flexible assortment of NI signal conditioning modules (provided by the client).

The software used an object-oriented Actor-based architecture, which facilitates adding new signal conditioning modules and flexible communications between the host PC and the real-time controller.

| SOFTWARE FUNCTIONS |

|---|

| DAQ Task Configuration |

| Event-Based DAQ Trigger |

| Data Synchronization |

| Real-Time Data Visualization |

| Data File Playback Utility |

| Datalogging to TDMS File |

| HARDWARE USED |

|---|

| PXIe Chassis (4,9 or 18-Slot) |

| PXI Real-Time Controller |

| PXI Multifunction I/O Module |

| PXI Digital I/O Module |

| PXI Counter/Timer Module |

| PXI Thermocouple Module |

| PXI DSA Module |

| PXI LVDT Module |

| PXI High-Speed Bridge Module |

| PXI Voltage Input Module |

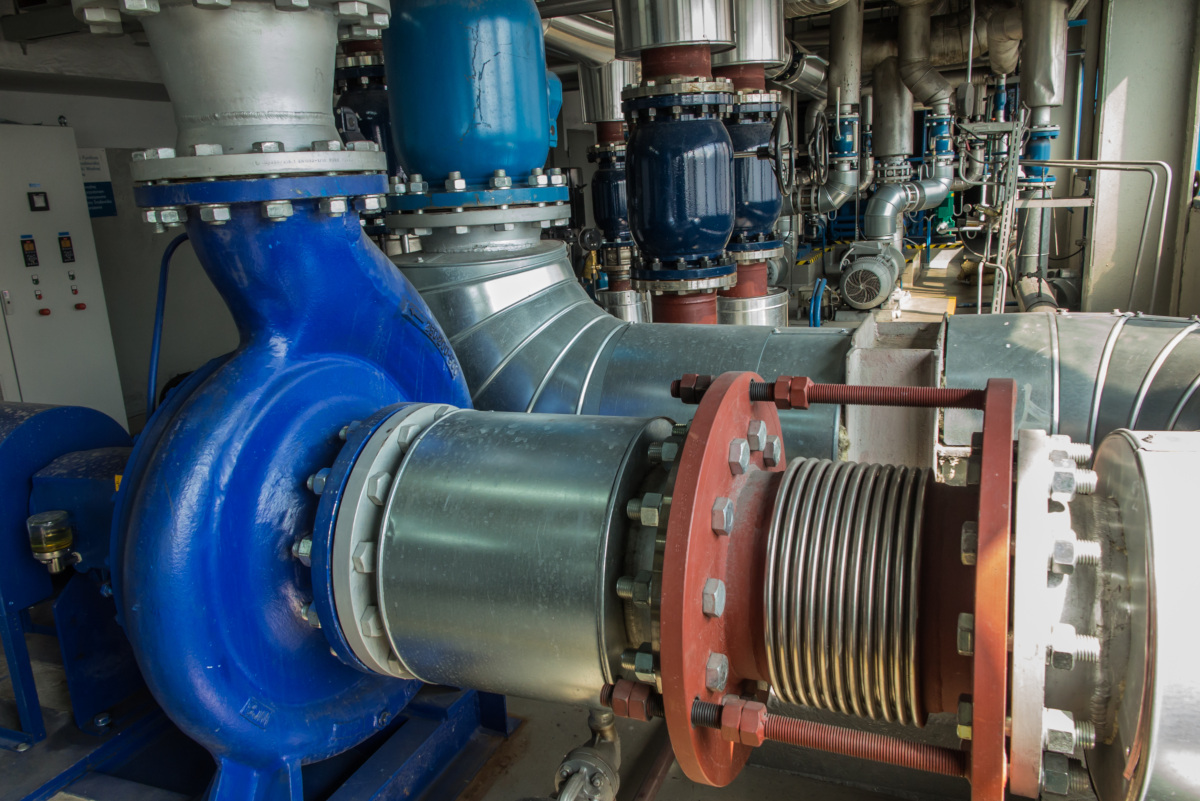

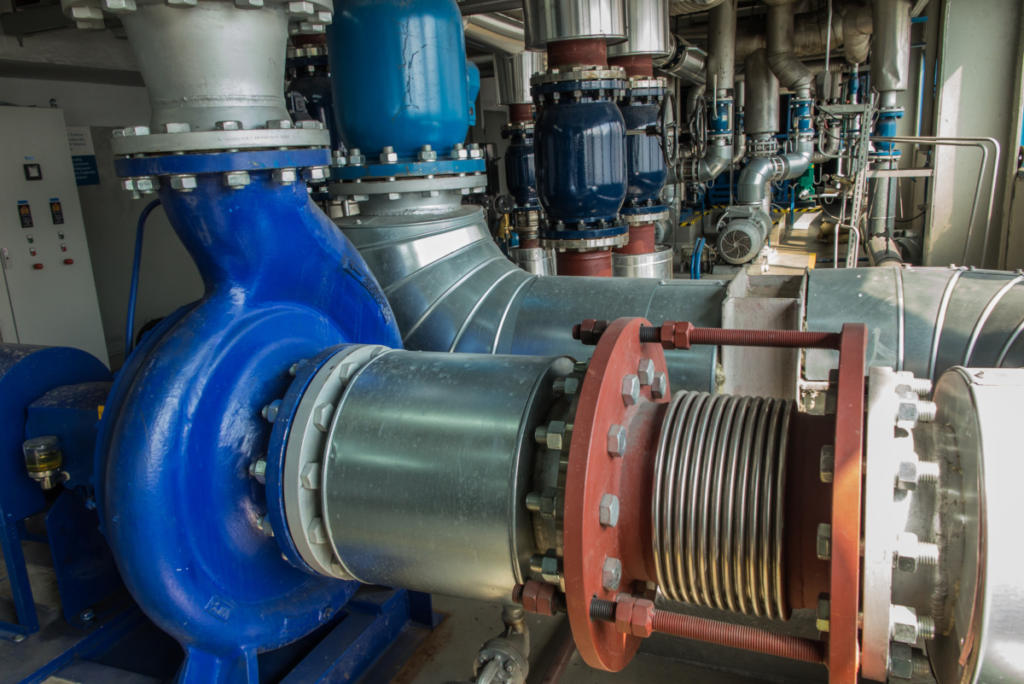

Pump Test Station – Increasing throughput

Pump Test Station – Increasing throughput

Standardizing on testing technique & reporting

Increasing test throughput with automation

Client – Industrial pump manufacturer

Challenge

Pump manufacturers typically test their product in the same facility in which the pumps are created. These tests are well defined and based on standards created by organizations such as API and ANSI to name a few. These tests are run to verify the performance of the pump as well as provide a report to the customer demonstrating that the pump they purchased will meet their needs. Sometimes these tests become factory witness tests where the customer sits in on the testing being performed on the pumps they had purchased.

This particular pump manufacturer had a test facility where many different sizes and types of pumps could be tested. The software provided to them by another integrator to run the test stand had the desired user interface screens, but did not function as requested, and was missing certain desired features.

Our client came to us with the following requests:

- Evaluate the software written by the previous integrator to assess whether any of the code could be reused in the new application.

- Ensure that existing cDAQ hardware would be compatible with changes and improvements to the software.

- Deploy the hardware/software solution on the test site to verify it performed as required.

Solution

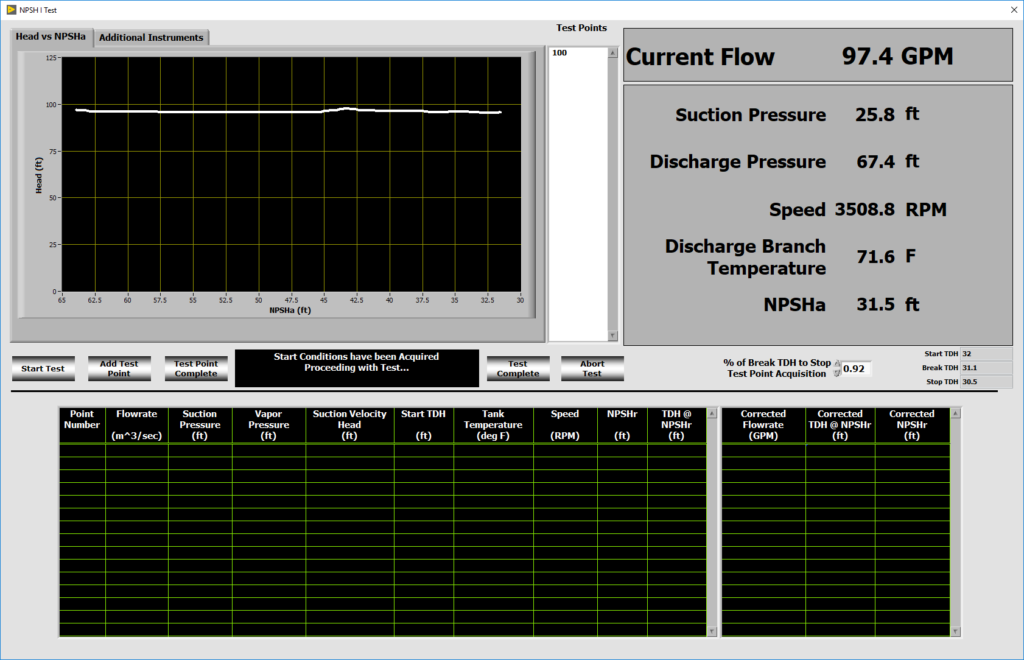

The Pump Test Utility was used for end-of-line test and product validation.

It had the following features:

- A Pump Test application that can run one of the following tests at a time:

- Performance Test.

- Net Positive Suction Head (NPSH) Test.

- Mechanical Test.

- All test configuration and data files generated by the software must be compatible with Microsoft Excel.

- Ability to show vibration data real time while the test is running.

Benefits

- Standardization of testing technique –each pump will be tested with the same procedures and calculations/algorithms.

- Automated generation of report content and presentation – automation of this step will save hours of manually recording data and entering that data into a spreadsheet to generate the same report.

- Automation of the reporting and elimination of the need to manually record data will increase throughput of the testing facility.

System Overview

We developed the Pump Test Utility application to allow our client’s engineers and operators to:

- Run one of three guided tests that visually provides pump performance feedback during the test.

- Create a test configuration user interface that will be used to store configuration information that can be recalled when testing a similar pump.

- Automate the collection of data during the test.

- Automate the population of report templates with the configuration and data acquired during the test.

- View and print out vibration graphs real time during the test.

The pump test software was developed in LabVIEW.

It interfaced with simple delimited text files and Excel workbook templates to save the configuration information necessary to set up and run the required tests.

The resulting data acquired during the test, both raw data acquired from the sensors and calculated data used to characterize the pump being tested, are saved to delimited text files.

Both high-speed (10 kS/s) and low-speed (10 S/s) data are acquired. High-speed data are graphed real time in a separate UI that allows the user to set cursors on the graph for visualization and printing to a pdf report.

Low-speed data is written to a delimited text file for archival storage and retrieval if additional analysis is required.

The high-speed data are for vibration measurements. The low-speed data are for pressure, temperature, RPM and flowrate measurements.

Flow rate and vacuum pressure were automatically adjusted using a PID loop and 4-20 mA controlled valves.

The pump test configuration is performed within the application from a series of drop-down selections populated with sensors found in an Excel workbook. The Excel workbook is updated and maintained outside the application. Once the test sensors and conditions have been selected, those selections are written to an Excel workbook for use in the reports.

The Excel ActiveX interface was used to develop the reports the client provided to their customers for the slow data. The Excel workbook template contained the formatting necessary for the reports. As the software wrote the data into the workbook, the reports were built from the formulas and formatting already configured in the Excel template.

At the end of the test, the software printed the appropriate worksheets containing the elements of the report required. The vibration (high-speed data) is written to a binary file and a pdf.

| SOFTWARE FUNCTIONS |

|---|

| Data Acquisition |

| Test Sequencing |

| 3 Standardized Test Types |

| Generate Standard Table-Based Reports |

| Generate Pump Performance Graphs |

| Generate Vibration Graphs |

| Sensor Management Tools |

| Test Configuration Management Tools |

| HARDWARE USED |

|---|

| NI cDAQ Signal Conditioning Chassis |

| Variety of NI cSeries Signal Conditioning Modules |

| Pressure Sensors |

| Level Sensors |

| Flowmeters |

| Vibration Sensors |

| Displacement Sensors |

| Temperature Sensors |

| Torque Sensors |

| Speed Sensors |

Pump Test Station

Pump Test Station

Client – Industrial pump manufacturer

Standardizing on testing technique & reporting

Reducing the number of pumps in the production queue

Challenge

Pump manufacturers typically test their product in the same facility in which the pumps are created. These tests are well defined and based on standards created by organizations such as API and ANSI to name a few. These tests are run to verify the performance of the pump as well as provide a report to the customer demonstrating that the pump they purchased will meet their needs. Sometimes these tests become factory witness tests where the customer sits in on the testing being performed on the pumps they had purchased.

Most pump manufacturers have more than one testing site at a facility to accommodate different pump types and sizes. The ability to automate these tests and to present a common look to the testing process and reports make the customer experience more positive to those reading the reports and/or witness the testing.

Our client came to us with the following requests:

- Evaluate the software written by the previous integrator to assess whether any of the code could be reused in the new application.

- Specify a hardware and software solution to acquire the signals needed to compute the performance results for standard tests.

- Deploy the hardware/software solution on the first test site to verify it performs as required and then deploy to the remaining test sites at their facility.

Solution

The Pump Test Utility had the following features:

- A Pump Test application that can run one of two different tests; a performance test and a net positive suction head (NPSH) test.

- An Access database was used to store the available sensors for that test site. The user selected the appropriate sensors while configuring the test.

- The test data was stored in an Excel file where each pump received its own Excel file.

- The LabVIEW Report Generation toolkit was used to populate the Excel file with data as well as create the report for the pump

Benefits

- Standardization of testing technique – now each pump will be tested with the same procedures and calculations/algorithms used are standardized across all test sites within the facility.

- Standardization of report content and presentation – now every customer that purchases a pump from our client will receive a report with identical information presented and that information will have been derived from the same calculations/algorithms.

- Reduction of the number of pumps in the production queue (and hence inventory) by roughly as much as 1/2 due to faster data acquisition and especially the archiving of the test results and the generation of the final report and its associated calculations.

System Overview

We developed the Pump Test Utility application to allow our client’s engineers and operators to:

- Run one of two guided tests that visually provides pump performance feedback during the test.

- Create a test configuration file based on an Excel template that will be used to store test data as well as generate a report.

The pump test software was developed in LabVIEW and interfaced with an Access database and Excel workbook to acquire the configuration information necessary to set up and run the required tests. The resulting data acquired during the test, both raw data acquired from the sensors and calculated data used to characterize the pump being tested, are saved to the Excel workbook. Both high speed (10 kS/s) and low speed (10 S/s) data are acquired and stored into one data file for archival storage and retrieval if additional analysis is required. The high-speed data are for vibration and sound measurements and low speed data are for pressure, temperature, RPM and flowrate measurements.

The pump test configuration is performed within the application from a series of drop down selections populated with sensors found in an Access database. The database is updated and maintained by the client through a series of user interfaces within the application. Once the test sensors and conditions have been selected, those selections are written to the Excel workbook for use in the reports.

The LabVIEW Report Generation Toolkit software was used to develop the reports the client provided to their customers. The Excel workbook template contained the formatting necessary for the reports. As the software wrote the data into the workbook, the reports were built from the formulas and formatting already configured in the Excel template. At the end of the test, the software printed the appropriate worksheets containing the elements of the report required.

| SOFTWARE FUNCTIONS |

|---|

| Data Acquisition |

| Test Sequencing |

| Metric or SAE Units |

| Multi-Level User Authentication |

| 2 Standardized Test Types |

| Generate Standard Table-Based Reports |

| Generate Pump Performance Graphs |

| Generate Vibration Graphs |

| Sensor Management Tools |

| Test Configuration Management Tools |

| HARDWARE USED |

|---|

| NI cDAQ Signal Conditioning Chassis |

| Variety of NI cSeries Signal Conditioning Modules |

| Pressure Sensors |

| Flowmeters |

| Vibration Sensors |

| Displacement Sensors |

| Temperature Sensors |

| Torque Sensors |

| Speed Sensors |

Industrial Monitoring for a Harsh Environment

Industrial Monitoring for a Harsh Environment

Developing an industrial monitoring system for ultrasound-based sensing in a harsh environment

Client – Energy Research Lab

Challenge

Our client was experiencing problems making temperature measurements in a hostile, irradiated environment. Traditional temperature sensors don’t last long in this environment, so our client was developing a sensor designed for these conditions.

Special equipment is required to drive this sensor. It’s an active sensor requiring an ultrasound pulser/receiver (P/R) and high-speed digitizer to make it function.

The prior attempt the client made at using an original set of special equipment was having reliability and connectivity issues. This reduced reliability was of critical concern due to the requirement for the sensor to operate for years without downtime.

In addition, the existing application was incapable of displaying live data and lacked a user-friendly interface. On top of that, data analysis had to be done after the application was run, causing delays.

Our client needed reliable and robust hardware to drive the sensors and an application that would eliminate the challenges associated with the existing system.

Solution

Viewpoint accomplished the following:

- Evaluated two different ultrasonic P/R sensor driver hardware solutions to select a solution that would provide the connectivity robustness, configurability, and correct sensor driver characteristics required for the given sensors.

- Decoupled the digitizer embedded in the original P/R by adding a PXI digitizer with better capability.

- Provided backward compatibility with previous measurement hardware to aid in performance comparisons with the new hardware.

- Developed a LabVIEW-based application that corrected all the issues with the existing application including real-time data analysis, real-time data visibility and a modern user interface. The new application also provided sensor performance traceability using the sensor’s serial number.

Benefits

The enhanced measurement system offers the following benefits:

- Reliable sensor subsystem to ensure uninterrupted data acquisition.

- Measurement hardware configurability for sample rate, collection duration, and pulsing repetition rate.

- Application configurability for automating the analysis, historical archiving, and results reporting.

- Real-time data analysis.

- Sensor traceability through serial number and data files.

- Engineering mode to take control of the entire measurement system.

- Improved data logging to include raw and analyzed data.

- Improved application user experience via robust data collection and configurability.

System Overview

The deployed temperature monitoring system consisted of the following components:

- COTS pulser/receiver hardware for driving the sensors.

- COTS high-speed DAQ for retrieving ultrasound signals.

- A LabVIEW-based software application to provide real time data monitoring, error/alarm notification, data analysis, data logging, part traceability and backward compatibility with the older sensor driver hardware.

| SOFTWARE FUNCTIONS |

|---|

| Acquire Data from Sensor Driver Device |

| Data Analysis |

| Write Raw Data to File |

| Write Analyzed Data to File |

| Configuration Utility |

| HARDWARE UTILIZED |

|---|

| Sensor Pulser/Receiver Driver |

| NI PXIe Expansion Chassis |

| NI PXI Oscilloscope Module |

| NI PXI Thunderbolt 3 Module |

| INTERFACES / PROTOCOLS |

|---|

| RS-232 |

| Thunderbolt 3 |

High-Speed Digital Subsystem Emulator

High-Speed Digital Subsystem Emulator

Client: A large company involved in C4ISR

At maximum throughput, the AEDIS systems needed to consume and produce more than about 800 MB/s/slot.

Background

A large company involved in C4ISR was developing a system for a new high-speed digital sensor device. Viewpoint was contracted to build a test system used in design validation and ultimately endurance testing of the sensor. Since the sensor was a component of a larger system which was being developed at the same time, another test system was created to simulate the sensor by feeding signals into the system. This ability to use HIL testing for both the sensor and the downstream sensor electronics enabled parallel development, thus saving time and reducing schedule.

Challenge

Both the amount of data and the frequencies of the various digital signals were nearly at the limit of hardware capabilities. At maximum throughput, the systems needed to consume during record and produce during playback about 800 MB/s/slot. The FPGA clock on the FlexRIO had to run up to 300 MHz. The skew between triggers for data transmission needed to be less than 5 ns even between multiple FlexRIO cards even when the parallel data paths have inherent skews associated with the sensor. Finally, the systems needed to handle clocks that might be out-of-phase.

Achieving these requirements required significant engineering design in the face of multiple possible roadblocks, any one of which could have eliminated a successful outcome.

Furthermore, as usual, the development timeline was tight. In this case, it was a very tight 3 months. Basing the solution on our AEDIS platform was critical to meeting this challenge.

Viewpoint’s Solution

To meet the timeline, we had to work in parallel across several fronts:

- LabVIEW-based application development for both record and playback

- LabVIEW FPGA development for marshalling data between the controller and DRAM

- Custom FAM circuit board design and build

- FlexRIO FPGA CLIP nodes and code for low-level data handling

Technical Highlights

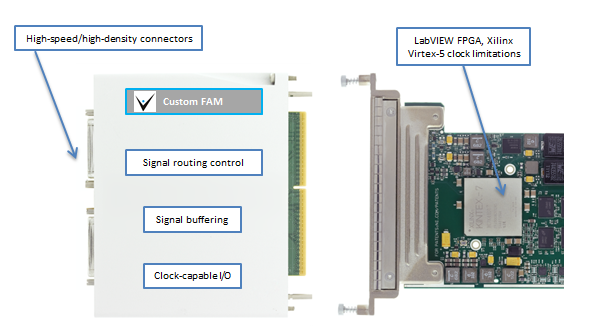

This sensor had several parallel data paths of clock and data lines with clock speeds up to 300 MHz on each path requiring exacting design and build of a custom FlexRIO Adapter Module (FAM) and unique custom CLIP nodes for extending the FlexRIO FPGA capabilities. The FAM also had a special connector for interfacing to the customer’s hardware.

Additional NI hardware and software completed the system components.

Results

The choice to base the AEDIS emulators on NI hardware and software was critical to completing this project. The open architecture in both hardware (custom FAM) and software (CLIP Nodes) enabled us to include some very creative extensions to the base toolset without which the project would not have succeeded in the allotted pressured schedule and on a predetermined budget. We were able to stretch the capabilities of the hardware and software very close to their maximum specifications by combining COTS and custom much more cost effectively than a purely custom design. Further, with HIL tests, both the sensor and the sensor electronics could be developed in parallel, leading to a significant schedule buyback for our client.

LabVIEW Layers

The host application, written in LabVIEW, managed the configuration of the data acquisition and the control of the LabVIEW RT-based FlexRIO systems. The configuration primarily dealt with the number of sensor channels in use, skew settings between digital lines, and other parameters that dealt with the organization of the data passed between the sensor and the FlexRIO.

Two FlexRIO applications were written, one for record and one for playback. Each FlexRIO application was written in LabVIEW, and managed the configuration of the FlexRIO cards and the movement of data between the FlexRIO cards and the RAID drives. Note that Windows supported for the RAID driver. Between 10 and 32 DMA channels were used for streaming, depending on the number of sensor channels being used.

And, each FlexRIO application had an FPGA layer, written in LabVIEW FPGA enhanced with custom CLIP nodes. For the record application, we developed a custom DRAM FIFO on the FPGA to assist with the latencies on the PXIe bus. For the playback application, we were able to stream directly from DRAM.

FlexRIO Considerations

The FlexRIO and stock FAMs from NI were initially considered as candidates for this project. Clearly, working with commercial-off-the-shelf (COTS) components would be most effective. Three options were available at the project start which could accommodate the required clock frequencies, but none offered both the required channel counts and skew/routing limitations. Hence, we had to design a custom FAM. This decision, made before the start of the project, turned out to be wise in hindsight because the parallel development path resulted in some shifts of sensor requirements which could be accommodated with the custom FAM but might have led to a dead-end with a COTS FAM.

FlexRIO CLIP

In LabVIEW FPGA, a CLIP Node is a method to import custom FPGA IP (i.e., code) into a LabVIEW FPGA application. CLIP stands for Component-Level Intellectual Property. We needed to use special Socketed CLIP Nodes (i.e., VHDL that can access FPGA pins) for this project because we could expose additional features of the Xilinx Virtex-5 not exposed in LabVIEW FPGA by accessing Xilinx primitives. Some specific features were:

- Faster FPGA clocking

- Additional clocking options

- Individual clock and skew control

- Custom PLL de-jitter nodes

Essentially, the FPGA design had a majority of FPGA code developed in LabVIEW FPGA and we used CLIP Nodes for interfacing the signals between the FlexRIO and the FAM.

FlexRIO Adapter Module

As mentioned earlier, we had to create a custom FAM because of the need to route high speed signals from customer-specific high density connectors while synchronizing signals across multiple data channels and FPGA modules to within one (300 MHz) clock cycle.

At these high-speeds, the FAM needed careful buffering and impedance matching both on the signals as well internal components on the FAM PCB. At the start of the design, we utilized Mentor Graphics HyperLynx High Speed DDR signaling Simulation software to minimize signal reflections prior to building actual hardware. This step saved countless hours in spinning physical hardware designs.

We designed the FAM to allow channel routing and access to additional clock and trigger pins on the Xilinx chip and PXIe backplane.

Pump Test Station Used Across Multiple Locations Worldwide

Pump Test Station Used Across Multiple Locations Worldwide

Client – ITT Goulds Pumps

Challenge

Pumps are used for everything from sump pumps for the consumer home market all the way to large pumps for industry capable of moving thousands of gallons per minute. Just as varied is the fluid being pumped: from water to slurries to hydrocarbon-based fluids.

Pump manufacturers typically build and test in plants across the world and each of those facilities is responsible for testing every pump manufactured at that site to ensure that the pump will perform as the customer expects. These tests are well defined and based on standards such as API, ANSI and other organizations. These standards provide test procedures but do not give details as to how to perform the tests. Each site typically tests their product without guidance as to how to satisfy the aforementioned standards. As a result, differing hardware and software solutions are usually put in place to test the individual site’s products.

Such varied testing systems make it exceedingly difficult to compare test results across testing sites, both within plants and between plants.

We were asked by our client to create a homogeneous test platform with which they could compare data across manufacturing plants and test sites within the plants as well as automate calculations of plant performance metrics and reporting.

This client engaged us to develop and implement a software and information storage solution that could run the prescribed tests on any testing site and make these data available to their engineers. These tests were to be semi-automated and guide the test operator through a test ensuring that the procedure and the resulting data were collected in the same manner on every test site, worldwide.

Solution

The Pump Test Globalization application consists of the following sub-applications:

- A Pump Test application that can run 1 of five different tests simultaneously to reduce the amount of time the UUT is under test. A separate data file is generated for each test and those data files are stored in the database along with the test results.

- A Test Configuration application that helps to manage the orders and the tests association with those orders.

- A Report Generation application that creates a report for each test run on a pump. Additional performance graphs are generated along with options for graphs depicting vibration and orbital performance of the pump.

Benefits

- Standardization of testing technique – now each pump will be tested with the same procedures and calculations/algorithms used are standardized across all manufacturing test sites.

- Standardization of report content and presentation – now every customer that purchases a pump from our client, regardless of origin of manufacture, will receive a report with identical information presented and that information will have been derived from the same calculations/algorithms.

- Ability to generate manufacturing performance data – metrics such as first pass yield may be calculated for all manufacturing sites. Data from all manufacturing sites may now be compared.

- Abstraction of data acquisition hardware – measurement data can be acquired from a variety of sources including OPC servers and NI DAQ Hardware. With this abstraction, the client’s existing hardware was reused where it made sense and replaced with new hardware as needed.

System Overview

We developed Pump Test, Pump Test Configurator and Pump Test Report Generator applications to allow our client’s engineers and operators to:

- Run one or a series of guided tests that visually provides pump performance feedback during the test.

- Configure a test for a specific pump model number and serial number. This configuration is read in by the Pump Test software to set up the test according to the configuration.

- Generate a report that would be sent with the pump to their customer showing how the pump performed and that it met the customer’s requirements.

The pump test software was developed in LabVIEW and interfaced with a SQL database to acquire the configuration information necessary to set up and run the required tests. The resulting data acquired during the test, both raw data acquired from the sensors and calculated data used to characterize the pump being tested, are saved to the database. Both high speed (10 kS/s) and low speed (10 S/s) data are acquired simultaneously and stored into one data file for archival storage and retrieval if additional analysis is required. The high-speed data are for vibration and orbital measurements and low speed data are for pressure, temperature, rpm and flowrate type measurements.

The pump test configuration software was also developed in LabVIEW and is a separate application that uses a SQL database on the back end. The database is located on a secure server and has been designed to retain the following information:

- Lists of all the manufacturing and test facilities.

- List for all the motors used for running the pumps.

- List for all the available sensors and hardware for each test station for every manufacturing plant.

- Ability to associate each sensor with a hardware channel for acquisition.

- Create and edit orders that contain pump specific information such as model number and serial number.

- Create and edit test configuration information for a given order.

The report generation software was also developed in LabVIEW and provides the user a means to create standard reports for each of the test types. Additional addendums to the standard report can be created to include graphs utilizing the high-speed data such as vibration and orbital information.

| SOFTWARE FUNCTIONS |

|---|

| Data Acquisition |

| Test Sequencing |

| Test Configuration Verification |

| Language Localization |

| Metric or SAE Units |

| Multi-Level User Authentication |

| 5 Standardized Test Types |

| Generate Standard Table-Based Reports |

| Generate Pump Performance Graphs |

| Generate Vibration and Orbital Graphs |

| Pump Order Management Tools |

| Sensor Management Tools |

| Test Configuration Management Tools |

| HARDWARE USED |

|---|

| NI cDAQ Signal Conditioning Chassis |

| Variety of NI cSeries Signal Conditioning Modules |

| Various OPC Servers for PLC Communications |

| Pressure Sensors |

| Flowmeters |

| Vibration Sensors |

| Displacement Sensors |

| Temperature Sensors |

| Torque Sensors |

| Speed Sensors |

Custom Endurance Test System – for a medical device

Custom Endurance Test System – for a medical device

Increased level of automation allows for multi-day and multi-week test runs

Client

A medical device manufacturer

Challenge

Our client wanted to improve the endurance testing of an implantable medical device product to help determine the recommended lifetime of the product. An obsolete test system existed, but the client wanted improved performance, UX and configurability. They wanted to just hit the “go” button and let it run for days or weeks. They also needed to be able to have new features added after the first release.

Solution

The custom product validation endurance test system utilizes NI cDAQ off-the-shelf hardware combined with custom LabVIEW-based software to provide automated N-up endurance testing of the UUT.

Benefits

- Higher fidelity DAQ

- Increased configurability of the system to run tests the way the client wants to

- Increased level of automation allows for multi-day and multi-week test runs.

System Overview

The endurance tester physically stresses the UUT to measure force and eventually breakage events. These events are used to help determine the recommended lifetime of the product. The tester tests multiple UUTs in parallel in order to gather more data faster for statistical validity. The system collects data until all UUTs break or the operator stops the test.

Viewpoint provided the software and advised DAQ hardware selection. The rest of the test system hardware was selected and assembled by the client.

The automated test system applies a varying cyclical force to multiple UUTs while measuring the force applied to the device. The software automates the data acquisition, analysis, load application, and motor during a test. The system measures all forces applied simultaneously while synchronizing that data to a cycle counter. That data is analyzed to determine average, maximum, and minimum force applied to the device over a user configurable number of cycles.

While running there are multiple alarm states that are monitored. When these alarm states occur, a file can be generated to dump a user configurable duration of force measurements to a file. Other alarms generated trigger the system to change a digital output state triggering a text message to be sent to the operators of the system. The system was designed to test for weeks at a time.

| SOFTWARE FUNCTIONS |

|---|

| Test Sequencer |

| UI |

| Data Logging |

| Report Generation |

| Breakage Event Detection |

| HARDWARE USED |

|---|

| NI cDAQ |

| Multiple NI load cell cSeries modules |

| NI cSeries Digital Input module |

| NI cSeries Digital Output module |

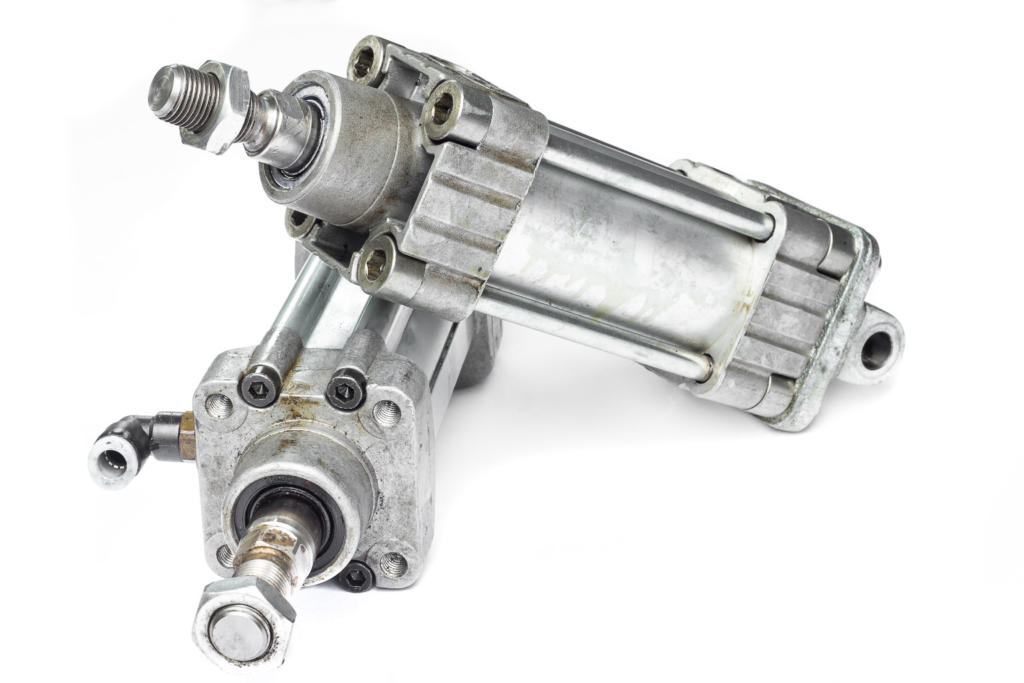

Endurance and Environmental automated test system for electro-mechanical sub-system

(image is representative, not actual)

Endurance and Environmental automated test system for electro-mechanical sub-system

Automating tests that run for weeks at a time

Client – Automotive component supplier

Challenge

Our client was already doing validation, but it was manual, and the client’s customer started requesting faster turnaround of results. Their customer was also requesting data to be sent with the results. Our client chose to automate the validation process to enhance their productivity.

Solution

Viewpoint utilized the (mostly) existing hardware from the manual tester and developed software to automate the testing. The LabVIEW-based automated test system allows for endurance & environmental validation testing of an electro-mechanical sub-system.

Benefits

- Automates tests that run for weeks at a time

- Logs errors during the test (e.g., for continuous monitoring tests, logging the number of instances of when a UUT’s LIN (Local Interconnect Network) response deviates from a static, current draw outside of limits)

- Capable of testing a large variety of product lines

- Logs pertinent data to a database for post-test analysis/inclusion into reports

System Overview

The UUT is an electro-mechanical part that falls under a variety of different product lines. As such, the client had a couple variants of the tester, based on the communication needs of the UUT. A total of more than a dozen testers were deployed. The functionality of the tester evolved over time, specifically modifying software to make the tests faster / decrease cycle time.

| SOFTWARE FUNCTIONS |

|---|

| Extensive diagnostic/manual operation of system for debug of software and electrical connections between the UUT and the test stand/tooling. |

| Product-specific software components to operate unique products. |

| Execute mechanical endurance tests. |

| Execute environmental endurance tests. |

| Database output containing results from every test cycle (either mechanical cycles or time depending on test being run). |

| HARDWARE USED |

|---|

| USB-LIN module |

| USB and PCI CAN Interfaces |

| Analog input card |

| Digital Input card |

| Digital Output card |

| Power Supplies |

| DMMs |

| Switch Matrix |

| INTERFACES / PROTOCOLS |

|---|

| CAN |

| LIN |

| USB |

| GPIB |

Product Validation of Mechanical Subsystem with NI cDAQ

Product Validation of Mechanical Subsystem with NI cDAQ

The updated product validation tester automates long tests, allowing the client to prove more obviously that their part met the specification.

Client – Automotive Component Supplier / Manufacturer

Challenge

The client already had a test system in place, but it was old and was becoming unmaintainable. Increasing demands from the test engineers and the old software architecture not lending itself to clean implementation of these new features (new sequencer capabilities and ECU CAN communication) drove the need for a rewrite of the software application.

Solution

The updated product validation tester supports product validation of the UUT by automating long tests (sometimes a week or more) providing the desired set point control, allowing the client to prove more obviously that their part met the stated specification. Viewpoint developed the software and the client selected the hardware.

Benefits

- Automate long duration tests

- Improved operator UX by making controls and indicators more intuitive to the user as well as providing additional capability within one application.

- Acquire ECU data along with measured UUT data to allow for engineering performance characterization analysis

- Playback utility enables the Test Engineer to quickly view collected data to chart out a path forward for further testing.

- Automate a Design of Experiments matrix of conditions, through new sequencer capabilities, to more quickly arrive at product characterization parameters.

- All collected signals are now housed in one TDMS file instead of multiple files from different applications.

System Overview

The UUT is a complete engine with a focus on one of the mechanical subsystems. Data is collected on over 100 channels, measuring temperature, vibration, strain, RPM, position and pressure. Engine management data (e.g., component location, pressures, engine speed, and status flags) is collected via CAN. The engine speed is set via an analog output, and subsystem setpoints are sent to the ECU via CAN. SCXI still used on some of the old test stands, but is being phased out in favor of cDAQ. The test system software was developed in LabVIEW.

| SOFTWARE FUNCTIONS |

|---|

| Test Sequencing |

| Data Visualization |

| Data Collection |

| Setpoint Control |

| HARDWARE USED |

|---|

| NI cDAQ |

| NI C Series Digital input module |

| NI C Series Digital output module |

| NI C Series Digital input/output module |

| NI C Series analog output module |

| NI C Series temperature input module |

| NI C Series analog input module |

| NI C Series strain/bridge module |

| INTERFACES / PROTOCOLS |

|---|

| Ethernet (TCP) |

| CAN |

Endurance Testing using NI PXI

Endurance Testing using NI PXI

An automated system permits faster validation, unattended test, an increase in throughput, and can free up resources for other tasks during the weeks long endurance test.

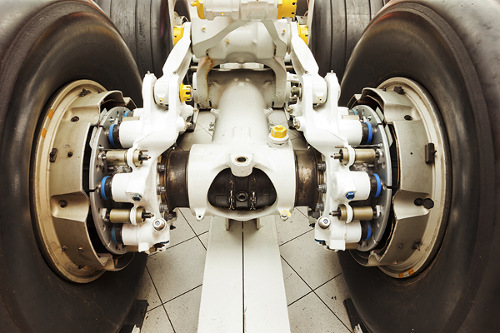

Client – A manufacturer of aircraft components in the mil-aero industry

Challenge

New product development drove the need for a new aerospace endurance test system for product validation. The old systems were not designed to test the newly designed part (aircraft actuators), and the company didn’t have the time or resources to reconfigure existing systems to perform the testing required.

Solution

The new PXI-based endurance test system provides automated electromechanical testing, full data recording, report generation and a diagnostic panel for intelligent debug. Viewpoint selected the NI equipment, while the test consoles, and other components were selected and fabricated by the customer.

Benefits

- This automated aerospace test system permits faster validation, unattended test, an increase in throughput, and can free up resources for other tasks during the weeks long endurance test.

- Full data recording with a data viewer enables post analysis, which provides the ability to review and analyze raw signals captured during execution. Channel examples are actuator LVDT position, load, current, and encoder actuator position.

- Summary report capability allows the customer to document the amount of testing completed against the full endurance test schedules.

- A manual diagnostic operational panel provides the ability to verify particular DUT functionality or components without running an entire schedule.

- Systems can be paused and restarted to allow for “scheduled maintenance” of the DUT such as inspections, lubrication, etc.

System Overview

The PXI-based aerospace endurance test system enables data collection, deterministic PID Loop Control, emergency shutdown and a diagnostic panel for manual test and debug operation. The system runs endurance test schedules, that are defined as a recipe for test execution. These schedules, which are customer-defined and DUT-specific, are designed to simulate the actual conditions the DUT would see in real world application as closely as possible. LabVIEW-RT was used for the deterministic looping for Closed Loop Control of Actuator Position and Load Control. LVDT demodulation was performed on a PXI FPGA card programmed with LabVIEW FPGA.

| SOFTWARE FUNCTIONS |

|---|

| GUI |

| Summary Reports |

| Full Data Collection for Real-Time and Post Analysis |

| Deterministic PID Loop Control |

| E-Stop Management |

| Diagnostics Panel for Manual Test and Debug |

| Endurance Test Schedule Execution |

| Hydraulic Control Panel for Source & Load PSI Control |

| HARDWARE USED |

|---|

| PXI |

| Various PXI-based Data Acquisition Cards |

| PXI RT Controller |

| PXI FPGA Card |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

Endurance Tester for Mission-Critical Mechanical Component using NI cRIO

Endurance Tester for Mission-Critical Mechanical Aerospace Component using NI cRIO

Ability to run tests unattended and overnight reduces operator labor and compresses test schedules

Client – Major Aerospace Component Supplier / Manufacturer

Challenge

The client had an older VB & PLC-based aerospace test system in place already, but it was obsolete. A new endurance test system needed to be developed to validate prototyped components (in this case, aircraft & aerospace bearings). Many of the prototypes are one-off, so it was important that the test system not destroy the component.

Solution

A new endurance test system was developed to validate prototyped aerospace components. The test system can be configured for automatic shutdowns so as not to destroy the component under test in the event of unexpected performance of electro-mechanical subsystem components. The updated endurance tester supports product validation by allowing the product to run under various test conditions (e.g. speed, load, oil flow, temperature) and collecting data for analysis.

Viewpoint developed the software and selected the NI hardware (other hardware was selected by the client).

Benefits

Ability to run tests unattended and overnight eases operator labor and compresses test schedules

Data collection allows for offline engineering analysis

Automatic shutdowns reduce destruction of the prototype component under test

System Overview

The updated cRIO-based endurance tester incorporates configurable profiles, data logging, and automatic shutdown to allow for safer extended validation testing. LabVIEW FPGA and LabVIEW RT were used together to interface with the test hardware sensors and controls. LabVIEW as used create the HMI for the test system.

| SOFTWARE FUNCTIONS |

|---|

| Closed loop control of bearing test oil flow |

| Axial load control |

| Driver for Emerson VFD |

| E-Stop and safety management (shutdowns based on alarm limits) |

| Data collection – temperature, pressure, flow, vibration, frequency |

| Operator/Diagnostic GUI for control of system |

| HARDWARE USED |

|---|

| NI CompactRIO (cRIO) |

| NI C Series Current Input Module |

| NI C Series Voltage Input Module |

| NI C Series Temperature Input Module |

| NI C Series Current Output Module |

| NI C Series Analog Input Module |

| NI C Series Sound and Vibration Input Module |

| NI C Series Digital Module |

| Emerson VFD (Variable Frequency Drive) |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

| TCP Modbus |

Endurance Tester using NI cRIO

Endurance Tester using NI cRIO

Multiple International Deployments Helps Prove Product Meets Spec.

Each endurance test can run upwards of 6 months.

Client: Major Automotive Component Supplier

Challenge

A new endurance test system was developed to give more precision in the control setpoint. This additional precision enabled potential clients to review the product performance in real-life situations. Each endurance test can run upwards of 6 months.

Solution

The updated endurance tester supports product validation by providing the desired parameter control method, allowing the client to prove more obviously that their part met the stated specification.

Viewpoint developed the software and selected the NI hardware for the first unit. The client is now deploying copies of this system to multiple international manufacturing plants.

Benefits

- Able to prove meeting a particular product specification of interest

- Closed loop parameter control

- Data collection

- Configurable Alarms

- Emergency shutdown functionality

System Overview

The cRIO-based endurance tester provides closed loop control, data collection, and alarming with controlled and emergency shutdown functions. The operator can manually configure a test or load a saved configuration. After a manual operator check to make sure the setup is operating correctly, a successful test will run its full duration and stop on its own.

| SOFTWARE FUNCTIONS |

|---|

| Touch PC interface / GUI |

| Closed loop parameter control |

| Data collection |

| Controlled & emergency shutdown |

| Alarming |

| HARDWARE USED |

|---|

| NI CompactRIO |

| NI analog input cSeries module |

| NI analog output cSeries module |

| NI digital input cSeries module |

| NI digital output cSeries module |

| INTERFACES / PROTOCOLS |

|---|

| TCP |

Product Validation using LabVIEW RT & LabVIEW FPGA – Electromechanical Actuator Test Stand

Product Validation using LabVIEW RT & LabVIEW FPGA – An electromechanical test stand for an aerospace actuator

Automated testing reduces operator man hours and increases production throughput.

Client – A manufacturer of actuators in the mil-aero industry.

Challenge

New Product Introduction (in this case a new controller and new actuators) drove the need for a new aerospace electromechanical test stand.

Solution

New NI PXI-based electromechanical test equipment provided automated HIL testing, report generation, and SPC data generation. The sequencing of the test procedure, reporting, and verifiable results were managed with the StepWise test executive platform.

Benefits

- Automated testing reduces operator man hours and increases production throughput.

- Meets strict customer requirements regarding testing and data recording in a verifiable manner.

- Automated Test Report Generation.

- Collects data to support SPC (Statistical Process Control).

- Ability to interact with the internal state of the controller FPGA via the LVDS communication link.

System Overview

Viewpoint developed the software and selected NI data acquisition and control hardware for the test stand. There are several layers of software functionality.

| HOST LABVIEW SOFTWARE LAYER |

|---|

| Test sequencer |

| Test steps (e.g. Frequency Response, Step Response, Dynamic Stiffness, Fault Response, Power Consumption) |

| Test Report Generator |

| GUI |

| REAL-TIME (RT) LABVIEW SOFTWARE LAYER |

|---|

| Data acquisition |

| 1553 comms |

| Function generator |

| Error detection |

| ESTOP |

| LABVIEW FPGA SOFTWARE LAYER |

|---|

| Synch data from 3 sources (tester, UUT, external DAQ device) |

| Stream high-speed data to disk |

| Stream high-speed data to analog outputs for HIL test |

| Custom communication protocol used by UUT over LVDS lines |

| HARDWARE RECOMMENDED |

|---|

| NI PXIe |

| NI FlexRIO card with LVDS adapter module |

| Multiple NI R Series cards |

| High speed, high voltage, isolated analog input cards |

| INTERFACES / PROTOCOLS |

|---|

| MIL-STD 1553 bus |

| LVDS |

| Ethernet |

| Custom TCP/IP |

*- images are conceptual only, not actual

Product Validation & Production Test System – For complex Mission-critical sub-system

Product Validation & Production Test System – For complex Mission-critical sub-system

Upgrade reduces per unit test time by ~40% and improves reliability of software

Challenge

The customer needed to upgrade their existing test system. Their old test system was very manual:

- It did not provide ability for unattended operation

- The thermal control had to be set manually

- They wanted to do less manual review of the data

The client develops mission-critical products, so there’s a desire to reduce manual operations because they have to explain any anomalies, and manual operations are typically more error-prone. They needed repeatable results that they could trust.

Solution

Viewpoint developed a new test system that utilized new hardware and software, augmented by existing low level hardware and firmware. The test system was developed to perform both functional test for production and environmental testing, and was designed to handle up to 4 DUTs at once. The test system utilizes the StepWise test executive software with custom test steps, which allowed the client to create their own highly configurable test sequences. The system was developed in two phases, with the second phase adding support for a FPGA expansion backplane (NI CompactRIO chassis) in order to provide future capability for bringing some of the microcontroller sequence activity into the NI space. In addition, the previous version had a mix of serial, TTL, and USB instrumentation, which was not as robust as Ethernet based instrumentation. Phase II involved upgrading to all Ethernet based instrumentation, and did away with the original test system’s many manual toggle switches that could be used instead of the programmable mode through the SW.

Benefits

- ~40% test time reduction per unit

- ~25% reduction in anomalies that needed to be justified

- ~500 manhours saved in test execution

System Overview

| Software Functions |

|---|

| Test sequencing |

| Test report generation |

| Data recording/logging |

| Error handling |

| Test GUI |

| Oscilloscope interface |

| Thermal chamber interface |

| Power supply interface |

| External custom hardware interface |

Designing an Automated Fuel Cell Validation Test Stand

Designing an Automated Fuel Cell Validation Test Stand

Verifying a New Fuel Cell Design Through Automated Operation

Client: A major automotive manufacturer

Problem Scope

Micro Instrument, an automation vendor that builds test and validation stands, has extensive experience with programmable logic controllers (PLCs) and stand-alone controllers for controlling repetitive motion, safeties, and other “environmental” parameters such as pressure and temperature. The company typically uses PLCs to reliably deliver discrete I/O control and standard PID loop control.

However, Micro Instrument’s customer, a major automotive company, was interested in investigating fuel cells as a power source and they needed to run these fuel cells under a wide range of conditions for extended durations, for both design validation testing and durability testing purposes. Furthermore, the client wanted to implement more advanced control algorithms than simple PID.

Challenge

The customer knew they needed control loops that predicted system response so we could eliminate overshoot and/or achieve a faster approach to a setpoint. But, because the customer did not know in advance exactly what such “smart” controls would entail, it was beneficial to have the full power of LabVIEW to develop such controls. Providing this functionality with a PLC would be cumbersome, if not impossible.

The customer had some Compact FieldPoint which they wanted to use for this project, so we needed to ensure that this equipment would be sufficient to deliver the required control performance and tolerances. Also, the system needed to conduct PID control in two forms – PWM and continuous control. Importantly, this Fieldpoint hardware had a real-time controller running LabVIEW Real-Time.

Solution

We developed a flexible control environment using NI Compact FieldPoint and LabVIEW Real-Time to meet the customer’s system control demands. For example, to predict system response, we programmed the Compact FieldPoint to run control loops that were aware of imminent system-state changes and changed their control schemes accordingly.