LabVIEW Consultants / LabVIEW Programming Services | LabVIEW System Integration

US-based manufacturers: Need a LabVIEW Expert?

Need some existing code updated? Need a whole new LabVIEW-based test system?

While we go by many names (e.g. LabVIEW experts, LabVIEW system integrators, LabVIEW consultants, LabVIEW specialists, LabVIEW programmers, LabVIEW developers), the key takeaway is that we can take the software development and hardware integration off your plate.

Capabilities & Expertise (LabVIEW and NI hardware related)

- LabVIEW-based automated test system development

Test system architectures including, as needed, state machines, actor framework, OOP, real-time on RT and FPGA, machine control, C#, and Python

- Agile Development (leveraging Microsoft Azure DevOps)

SVN & Git for source code control

LabVIEW data management

LabVIEW-based advanced test report development

LabVIEW-based remote access and remote monitoring

SQL database design and interfacing

Integrate with RESTful APIs in LabVIEW

Leverage gRPC Services in LabVIEW

Integrate .NET on CompactRIO

- Custom electronics design including signal conditioning

Communications using MIL-STD-1553, IEEE-1394b, and ARINC, Ethernet, gRPC, …

ITAR Registered

ISO 9001 certified

We have one or more:

Certified LabVIEW Architect

Certified LabVIEW Developer

Certified TestStand Architect

Talk to a LabVIEW Consultant. |

|---|

We’ve helped teams at some of the world’s most innovative companies

Testimonials

“Very impressed…kudos to Viewpoint”

I really want to thank you for all your help getting us to this stage in automating our testing. We had our customer in this week to oversee some testing and they were very impressed, which is definitely kudos to Viewpoint.

“Significant value”

The Viewpoint team provides significant value to our projects, and I really enjoy working with Viewpoint.

“Valuable part of our global team”

I have been working with Viewpoint for 15+ years on multiple projects. They have always provided creative and quick solutions to all of the problems we have placed in front of them. I have always considered them a valuable part of our global team.

LabVIEW Case Studies | Projects

Condition Monitoring for Electric Power Generation

Condition Monitoring for Electric Power Generation

Monitoring generator and turbine components of power generation equipment

The CompactRIO-based system has allowed for continuous monitoring, rather than just a periodic review of turbine and generator performance. In addition, by combining the FPGA and the RT processor in a physically small device, the solution has been able to ensure very fast data acquisition, data reduction, and sophisticated analysis.

Client: A multi-national power generation equipment manufacturer

Background

Continuous monitoring of power generation equipment can have a great impact on maintaining a reliable flow of power to consumers as well as alerting the power generation equipment operator to potential equipment damage if timely repairs are not made.

This case study will focus on two measurement systems utilized by a multi-national power generation equipment manufacturer to monitor the generator and turbine components of their power generation equipment.

The manufacturer’s systems needed relatively high-speed waveform sampling, well-suited to the National Instruments CompactRIO platform. Viewpoint Systems provided technical assistance in the development of these systems.

Challenges

The difference in the types of analyses and data rates of the measurement systems required a flexible yet capable hardware platform. Each system needed to work on a generator outputting 50 Hz AC or 60 Hz AC.

Viewpoint’s Solution

The CompactRIO platform and LabVIEW proved to be an excellent solution for the electric power generation condition monitoring system’s data acquisition and analysis needs. The small size and robustness of CompactRIO allowed the system to be placed at a preferred location. In both the flux probe and the blade tip timing, the CompactRIO FPGA could acquire and pre-process the data. The CompactRIO successfully managed – and continues to manage – all analysis, data archiving, and communication with a host PC.

In the case of the tip timing, the data rates were high enough that the detection of the tip location for each signal needed to be performed in the FPGA so that the real-time (RT) layer received a much-reduced data rate of tip locations. The RT processor was able to perform higher level analyses on these timings. Occasionally, a snapshot of a raw tip timing waveform could be passed to the RT processor for archiving and presentation to an engineer. However, due to the data bandwidth and processor loading of the CompactRIO, such snapshots must be infrequent.

For both systems, a master PC managed the operator user interface, long-term data collating, reporting, and archiving of files and statistics. Each CompactRIO connected to this master PC via a TCP/IP connection.

Results

The CompactRIO-based system has allowed for continuous monitoring, rather than just a periodic review of turbine and generator performance. In addition, by combining the FPGA and the RT processor in a physically small device, the solution has been able to ensure very fast data acquisition, data reduction, and sophisticated analysis. By deploying CompactRIO devices, the multi-national power generation equipment manufacturer achieved a cost-effective method of monitoring the power generation facility equipment, ensuring detection of operational issues quickly and easily.

Technical Highlights

Both measurement systems described required sampling rates greater than 10 kHz, restricting the use of traditional PLC-based data acquisition devices and requiring a programmable automation controller (PAC). Each system measured the performance by connecting to special sensors and associated signal conditioning, provided by our customer, such that the data acquisition equipment only needed to support ±10 V signals. Furthermore, each of these systems needed to push data to a master PC for data trending, result archiving, and operator display.

Despite the significant differences in the measurement types, Viewpoint Systems was able to utilize a common set of data acquisition, processing, and connectivity tools, based on the NI CompactRIO platform and LabVIEW, to monitor the system.

More information about each measurement system follows.

Flux Probe

The flux probe system looks for shorts in the windings of the generator. Each time a winding passes under the flux probe, the probe output increases. When a winding is shorted, the field created by the winding is reduced and detected as a lower amplitude output by the flux probe. The position of a shorted winding inside the generator can be located by measuring a key-phasor signal that pulses once per revolution and converting the timing offset of this weakened signal into an angular position. Both flux and key-phasor signals are measured at about 50 kS/s.

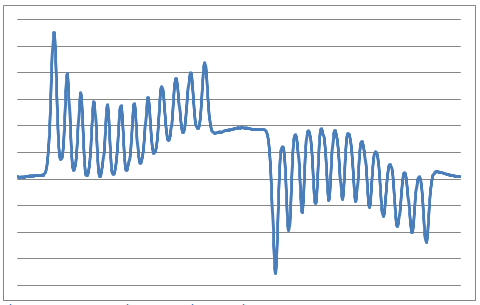

Figure 1 shows an example signal output by a flux probe. The local peaks are indicative of winding current. Automated analysis of the amplitudes of the flux signals can be challenging due to changing waveform shape as a function of generator load and severity of shorts.

Figure 1 – Example flux signal over a single rotation

A good reference of the flux probe technique is described in the Iris Power Engineering article, “Continuous Automated Flux Monitoring for Turbine Generator Rotor Condition Assessment.”

Turbine Tip Timing

The turbine tip timing system looks for displacement of each turbine blade tip from nominal position. At slow rotational speeds, the spacing between each tip closely follows the uniform blade spacing. At higher speeds, vibrations and resonances can make the blade tips wobble slightly, causing small deviations in the timing of the tip passing by a sensor.

A special proximity sensor detects the tip of the turbine blade, and can be based on optical, eddy-current, microwave, and other techniques. Any positional deviations of a tip from nominal give indications about the mechanical forces on the blade as well as compliance of the blade to those forces as the blade ages. Specifically, each blade has natural resonances and compliance, both of which can change if the blade cracks.

A turbine typically contains several stages and each stage contains many blades. See Figure 2 below for an example. The number of tip sensors per stage is variable; if blade twist is measured, at least two sensors are oriented perpendicular to the rotation direction. Also, the acquisition rate from each sensor is fast. For example, consider a stage with 60 blades, the width of each blade occupying about 1/10 the space between adjacent blades, and a generator running at 3600 RPM (60 Hz). The tip sensor would detect a pulse every 1/3600 s, lasting for less than about 1/36000 s, as the blades passed by. Accurate location of the pulse peak or zero-crossing then requires sample rates over 100 kS/s. Because multiple sensors are typically used, tip timing measurement systems can easily generate 10s of MBs of data per second.

Figure 2 – Example generator turbine blades

A good reference for the tip timing technique is described in the article by ITWL Air Force Institute of Technology – Poland, “Application of Blade-Tip Sensors to Blade-Vibration Monitoring in Gas Turbines.”

Remotely Monitoring Electrical Power Signals with a Single-Board RIO

Remotely Monitoring Electrical Power Signals with a Single-Board RIO

Electronics Design for sbRIO Mezzanine Card Combines Custom Needs with Flexibility

Client: A designer and manufacturer of leading-edge electrical power monitoring equipment.

Problem Scope

Smart Grid investment is growing. Two important premises for Smart Grid design are access to local power sources and an understanding of loads and disturbances on the grid at various locations. These local power sources are typically alternative, such as solar and wind, which have intermittent power levels. Since the levels fluctuate, an important feature of proper Smart Grid operation is handling these erratic supplies. Optimal understanding of these disturbances and load changes increasingly requires measurements on individual AC power cycles.

Challenge

Local power analysis systems typically have constraints in equipment cost, size, and power usage balanced against the need for simultaneous sampling front-end circuitry and custom data processing algorithms on the back-end. Furthermore, many of these systems are presently deployed as prototypes or short-run productions, requiring a combination of off-the-shelf and custom-designed components.

Technical Highlights

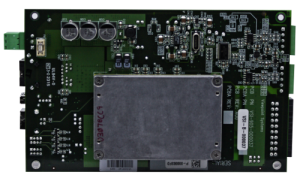

A custom RIO Mezzanine card was designed and built for the National Instruments Single-Board RIO platform to provide access to simultaneously-sampled signals from the 3-phase and neutral lines of an AC power source. Timing synchronization between physically-separated installations was provided by monitoring GPS timing signals. Custom VIs were developed to retrieve the sampled data points and GPS timing for subsequent processing and analysis.

Solution

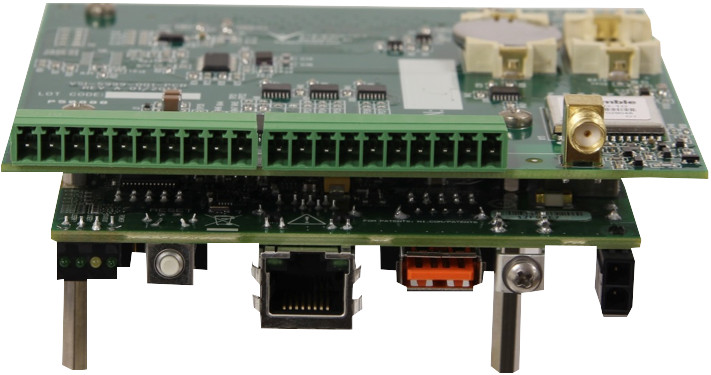

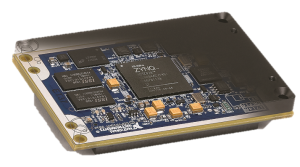

Figure 1 – Power Line Data Acquisition sbRIO RMC Module with GPS Timing

We needed 8 channels of simultaneously-sampled analog inputs (AI), each capable of sampling at least 50 kHz. These AI channels sample the voltage and current of the neutral and three phase power lines. Furthermore, to coordinate power and load fluctuations across many measurement locations, a world-wide synchronization signal is needed.

The Single-Board RIO (sbRIO) platform from National Instruments offers an excellent balance between off-the-shelf capability and custom design needs in a reasonably small package. The sbRIO provides the processor, memory, and connectivity while the RIO Mezzanine Card (RMC) provides the I/O and signal conditioning needs. See our white paper, Developing Embedded Systems: Comparing Off-the-Shelf to Custom Designs, for a discussion of the benefits of using this approach.

We designed the RMC for the simultaneously-sampled analog inputs and a GPS receiver. The RMC was mounted to a sbRIO-9606. Some design specifications were:

- 8 analog input channels: simultaneous sampling at 50 kHz, ±10 V range, 16-bit resolution

- GPS receiver with Pulse Per Second (PPS) timing signal with 60 ns accuracy

- SMA Connector for external GPS active antenna

- 20 position terminal block for analog inputs and shields, removable for wiring

- Operates inside an enclosure with internal conditions -40 to 55 °C temperature

An image of the designed RMC and the sbRIO-9606 is shown below. Since the A/Ds reside on the RMC, the data bytes are accessed by sbRIO FPGA VIs code communicating through an SPI data bus designed into the RMC. The internal real time clock coupled with the GPS PPS signal allowed for timing accuracy within a GPS region well under +/- 1 uS of accuracy for all data sampled no matter the location, internally or from unit to unit within feet or 1000s of miles away.

Conclusion

The combination of the sbRIO off-the-shelf platform and the custom RIO mezzanine card (RMC) for I/O makes a powerful, cost-effective, and yet configurable solution for measurements of AC power signals. With the GPS component on the RMC, measurement units can be placed at dispersed locations while still providing adequate synchronization of acquired waveforms for localizing and understanding disturbances in power transmission and distribution, irrespective of any specific application. If you have an embedded monitoring application that you’d like help with, you can reach out to chat here. If you’d like to learn more about our circuit board design capabilities, go here.

Industrial Embedded – Industrial Equipment Control

Industrial Embedded – Equipment Control – VAR Compensator

Keeping the Electrical Grid Healthy with VAR Compensation

Modular Embedded System Shortens Development Time and Reduces Risk in Static VAR Compensation System

Client: T-Star Engineering & Technical Services: A manufacturer of electrical power delivery equipment.

Background

The U.S. power grid is a large electrical circuit that, although has some amount of isolation between loads, is certainly interconnected at drop points, which is what customers care about most.

SVCs are generally worth considering in scenarios where large electric motors are being utilized (e.g. mills, recycling plants, mines). Problems such as voltage sag, voltage flicker, and current harmonics can cause reduced motor torque, lights to flicker, and equipment damage.

Challenge

T-Star has significant domain expertise in stabilizing medium voltage power systems. Viewpoint has significant domain expertise in the realm of measurement and control systems. The team at T-Star needed a well-supported intelligent device for their new generation Static VAR Compensator (SVC). They wanted a highly reliable solution that had minimized the time-to-market and a highly predictable future migration path for higher volume production. They also needed multi-channel precision timing, and high speed logging in a device certified for operation in dirty industrial environments.

Solution

Viewpoint was asked to develop the controller for T-Star’s Static VAR Compensator (SVC) using a carefully constructed specification. The chosen controller platform is a National Instruments (NI) Compact RIO due to its modular feature set, networking capabilities, and associated supportability and quality that comes with an industrial-grade off-the-shelf controller. T-Star and Viewpoint have made very complementary GSD (Get Stuff Done) teammates.

As the grid gains intelligence, this class of smart/dynamic power quality system will likely become more critical.

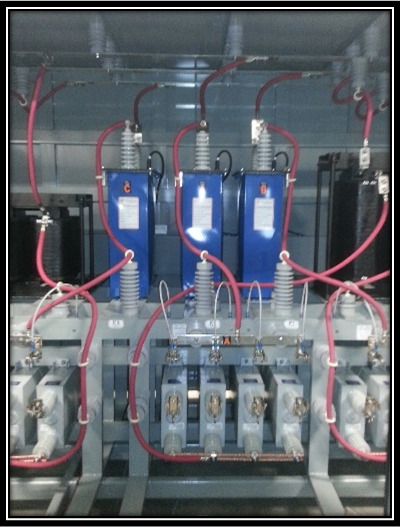

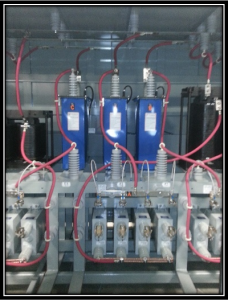

Cabinets for an SVC located at a remote mine in British Columbia

Inside an SVC

Benefits

- The platform supports other future configurations that are outside the phase one scope of this project.

- Time-to-market is critical for T-Star. The initial proof of concept was completed in weeks.

- The Linux-based OS, well known in the embedded community, provides a rich ecosystem for enhanced usability (e.g. network stack), and real-time operation.

- Secure access through VPN with built-in firewall and user account control and permissions allows for remote diagnosis, health monitoring, and gathering of online information.

- An FPGA allows for deterministic timing and parallel processing.

- With COTS hardware, future upgrades are simplified with code base reuse and recompiling for new hardware.

- The NI platform provides a migration path to a lower-cost solution once hardware configurations are locked down and production volumes increase above a certain level.

- The NI control hardware is certified (certifications in the domains of CE, FCC, UL, etc.) for marine applications and other challenging environments.

System Overview

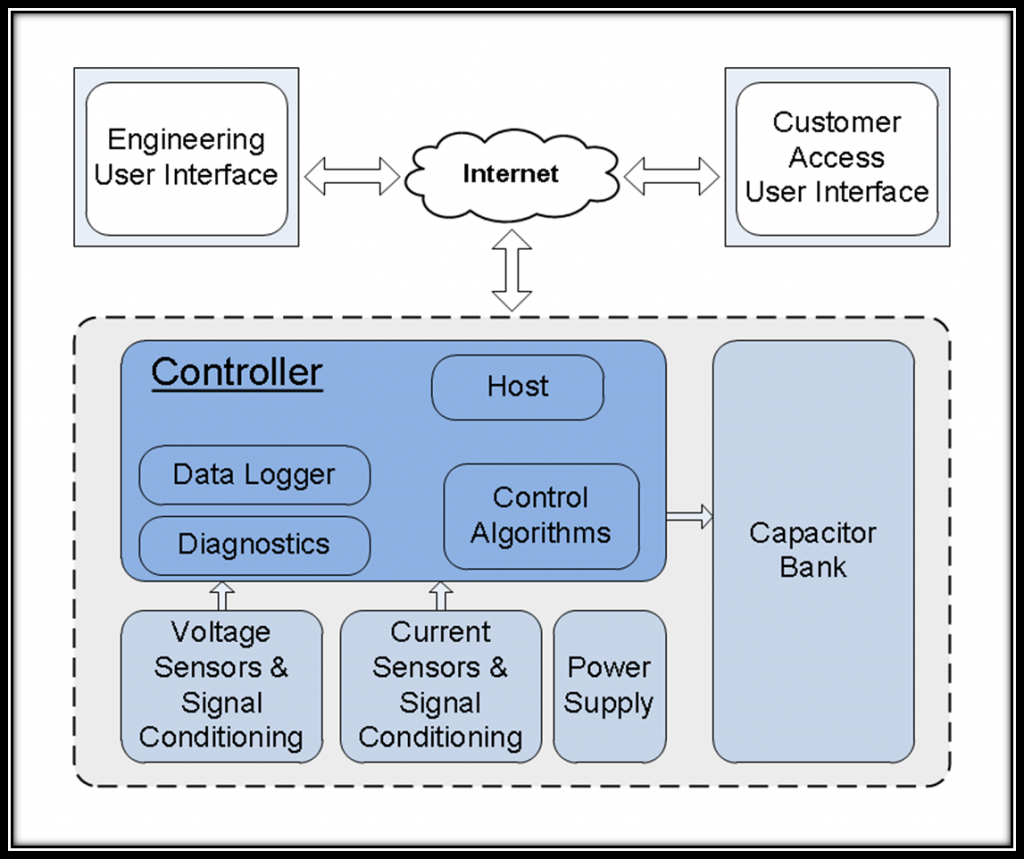

The SVC tunes a highly inductive load by dynamically injecting a variable amount of capacitance due to the measured load. Voltage and current sensors feed a series of control algorithms which determine the voltage and current imbalance in order to inject the appropriate amount of capacitance into the power system. This algorithm acts on a cycle-by-cycle basis. The figure below illustrates the system makeup.

Embedded Control for Industrial Machine – Gear Lapper

Embedded Control for Industrial Machine – Gear Lapping

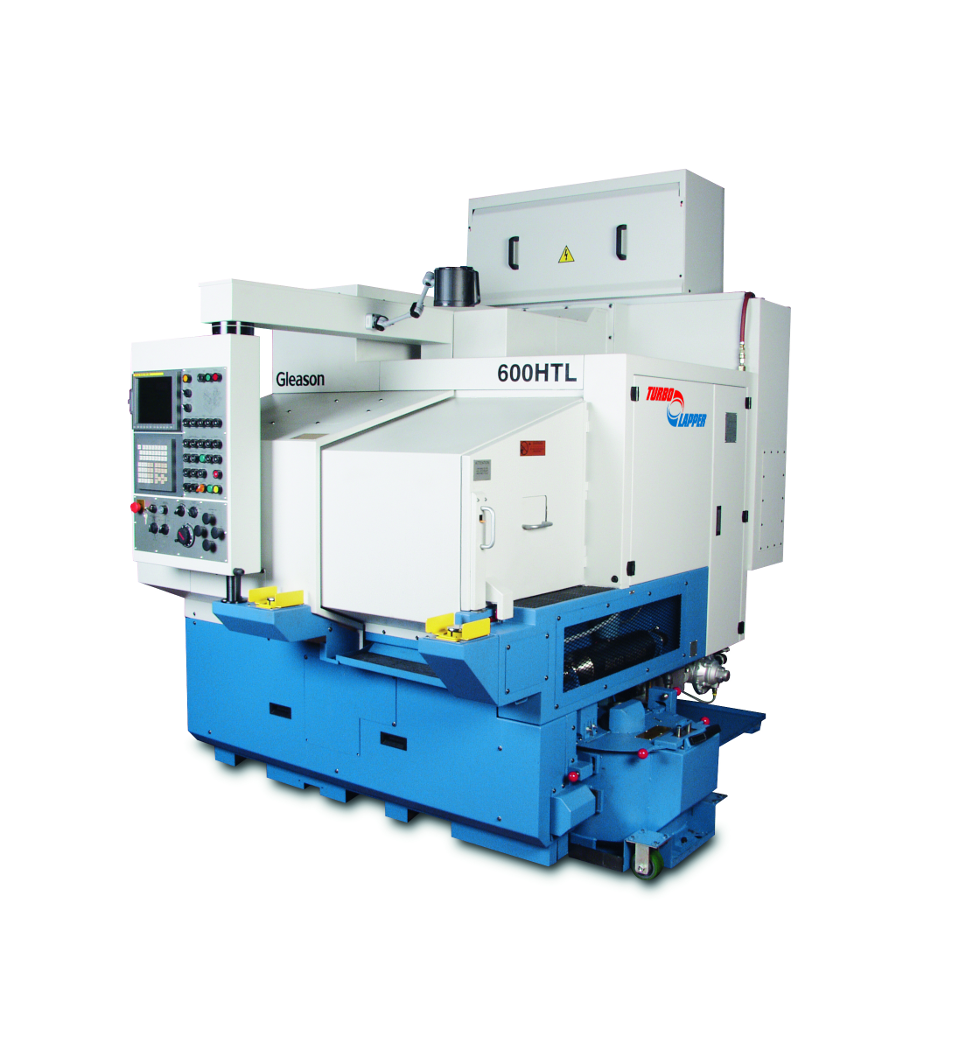

VIEWPOINT SYSTEMS IMPROVES GEAR FINISHING USING REAL-TIME EMBEDDED CONTROL SYSTEM WITH NI RIO HARDWARE.

THE GLEASON WORKS’ BEST-IN-CLASS GEAR MANUFACTURING SYSTEMS NOW PRODUCE HIGHER QUALITY GEARS IN 30% LESS TIME

With the embedded control system that Viewpoint created using NI

RIO hardware and LabVIEW FPGA, our customers can increase gear

quality and save cost at the same time.

Challenge

The Gleason Works sought to create a dynamic, torque-controlled lapping solution with responsive, realtime feedback to create better quality gears and reduce cycle time for its gear lapping machines.

Solution

Viewpoint Systems provided system integration using NI RIO technology and LabVIEW FPGA code for real-time measurement and control.

Background

Gleason Corporation and The Gleason Works create the machines, tooling, processes, services, and technologies needed to produce the bevel and cylindrical gears found virtually everywhere – from automobiles and airplanes to trucks and tractors, and from giant wind turbines that can power a thousand homes to the lawn mowers and power tools found at these homes. Gear tooth surfaces and spacing are never perfectly machined, and consequently, noise and vibration are often present in applications where the gears are later used. Gears, after the typical heat treatment process, are commonly lapped or ground to smooth the gear teeth surfaces and improve operational characteristics. The goal of lapping is to reduce surface and tooth spacing deviations that may produce noisy gear sets.

Gleason machines lap gears in pairs, the mating gear and pinion members rotating together at a high speed with an abrasive lapping slurry applied. After machining and heat treatment, however, the spacing deviations that need to be lapped are at unknown locations on the gears and can show themselves as run-out (i.e., an off-center axis). To further complicate finding the deviations, the run-out is actually composed of multiple orders, likely making the run-out for each order different than the others.

One conventional approach to lapping employs machines with relatively high-inertia spindles to carry the gearset members. At moderate speeds, this configuration can somewhat reduce spacing errors during lapping, but is far from optimal in refining the tooth surfaces. Another approach employs at least one low-inertia spindle. This configuration can refine tooth surfaces well, but tends to increase spacing errors—especially at higher speeds. In both conventional cases, one spindle is operated in a simple constant torque command mode to control lapping force, but the critically important dynamic torque components are left to passive physics.

To get the best of both worlds, Gleason could no longer rely on passive physics, and turned to Viewpoint Systems to help develop and implement an embedded control system that could measure deviations in real-time and apply dynamic corrective torque.

Results

With this new, patent-pending system founded on embedded control and dynamic real-time process monitoring technologies, Gleason and Viewpoint bring exciting new capabilities to a worldwide and well-established gear finishing process. The unprecedented ability to improve gearset quality during lapping, and to do so at higher speeds provides a winning market proposition—one made possible by intelligent application of today’s leading-edge technologies. With its new solutions, Gleason gear manufacturing systems now produce higher quality gears in 30 percent less time. Throughout the process, Gleason appreciated Viewpoint’s expertise and synergy achieved when working together. More than just an implementer, Viewpoint’s experts worked alongside their own to develop new techniques and solutions in an agile and collaborative environment.

Process

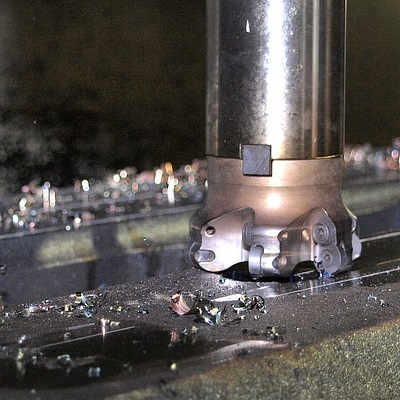

Gleason engaged Viewpoint Systems to implement this real-time measurement and control system because of their expertise with the leading reconfigurable I/O (RIO) hardware from National Instruments. Viewpoint used the NI RIO technology and developed LabVIEW FPGA code to create a real-time measurement and control solution for the lapping machine. Viewpoint equipped an NI cRIO-9076 controller with an NI 9411 digital input (DI) module and an NI 9263 analog output (AO) module. The DI module monitors two digital rotational encoders, one on each spindle carrying the bevel gear set members. Innovative analysis of these angular signals can tease out subtle variations in the average rotational speed. Coupled with sophisticated order analysis, these variations are used to modify the torque applied to the gear set at the proper angular positions and with the appropriate amplitude. Thus, the high-frequency dynamic torque components experienced by the gearset during lapping are no longer dominated by passive physics, but are actively controlled to achieve desired results. Viewpoint created the system to manage all of the measurements, analyses, and torque corrections in the RIO FPGA with specific, efficient coding in LabVIEW FPGA using Viewpoint’s FPGA IP toolset. The cRIO controller provides data collection and even data archiving functions to support other advanced post-processing. The controller also provides an API to control the adaptive lapping process from a supervisory application.

Improving Efficiency in Industrial Manufacturing Test

Improving Efficiency in Industrial Manufacturing

Simplifying Report Generation for High-Mix, Low-Volume Industrial Servo Valve Tests

Client: A major industrial servo valve manufacturer

Challenge

A manufacturer of components for both commercial and military aircraft built a large number of different models of servo valves. Some models were made only a few times each year, while other models were made with an order of magnitude higher volume. Each unit underwent rigorous testing during and after assembly.

Our client needed to submit the results of that testing to their customers but since the production and testing of each unit happened in many locations, possibly even around the world, many hours were spent locating the appropriate datasets and assembling the report.

Furthermore, our client wanted to improve their responsiveness to requests from their customers by having rapid retrieval of the test report for any part after it had been delivered into the field.

Solution

Since the test datasets were varied due to the large numbers of different valve models and associated test procedures, a database was created using a platform based on the Resource Description Framework (RDF). An RDF database can accept arbitrary types of data, manage that data through metadata tags, and adjust gracefully to changes in content and shape of the connections between objects in the database.

This adaptability was key to our client being able to leap past some of the issues in standard SQL-based relational databases.

The results from each test run on each part at each (PXI-based) test system were tagged with metadata and pushed into the RDF database. The StepWise test executive platform interfaced to the RDF database by outputting XML content which was scanned by a routine created for the RDF database and converted into the RDF data and links. The part ID was a critical tag since this allowed searching the RDF database for all results associated with that specific part. This database resided on a server at the client’s headquarters and accepted data from worldwide locations.

Once the data for each part was housed in the database, a report could be generated. To accommodate the variety of data in that report, web technology was used to render the report pages based on the types of data entered into the database, as described by the metadata tags. For example, data identified as waveforms could be plotted or listed in tabular format. Having reports rendered based on the data types made it possible to handle adjustments to the types of data measured by the test system.

Results

With the ability to render reports quickly, our client could produce detailed reports for their customers indicating the performance of any specific requested servo valve.

Our client was able to trim the time to create reports to less than 1 day from the previous effort of 3-5 days and with less error.

- Data are now organized uniformly, simplifying the location of desired information, as compared with files stored on various test PCs and file servers.

- The client has the ability to generate automatic emails to their customers with the required reports already attached and ready to go.

- In potential warranty and customer service situations, having the ability to send the customer a report within hours represented great customer service.

All these features are available consistently across worldwide manufacturing facilities, reducing training and maintenance of procedures. And, of course, the reports handle using metric or English units as appropriate for the end customer.

Decreasing Test Time for Aircraft Landing Gear

Decreasing Test Time for Aircraft Landing Gear

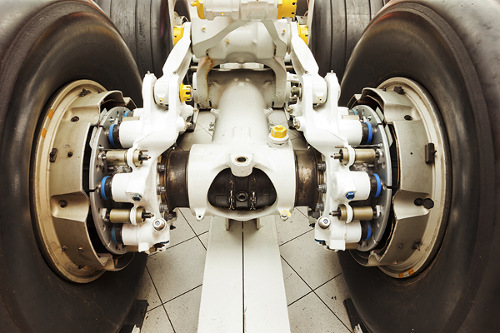

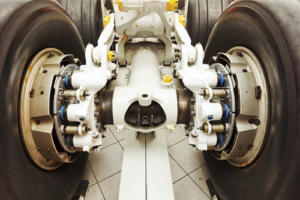

Endurance Testing for Aircraft Nose Landing Gear Steering

Client: A major manufacturer of aircraft landing systems

Challenge

A major manufacturer of aircraft landing equipment needed to develop a means of endurance and fatigue testing new designs for aircraft steering. The actuators involved in steering the nose landing gear (NLG) required precise and reliable control through thousands of steering cycles.

Control loops needed to be closed at faster than 1 ms.

Prior systems were handled manually without real-time control and monitoring.

Solution

Our customer designed and built a test rig to provide the hydraulics and environmental conditions for the endurance testing on the NLG. Viewpoint Systems supplied the electronic data acquisition and control hardware coupled with real-time software to provide the required fast control loops. The configuration and execution of the 1000s of steering cycles were managed by the same data acquisition and control system through a set of configuration screens that allowed specification of turn rates, min/max angles, drive and resistive torque settings, and so on. The flexibility offered with this HIL test capability mimicked the variety of conditions that the NLG would encounter in actual use.

- The various PID control loop configurations were also configurable along with gain scheduling required under different operating conditions.

- The environmental conditions were supported by controlling a temperature chamber through ramp and soak settings occurring during the steering tests.

- Measurements on the steering performance were collected from commanded setpoints, sensor readings, and controller outputs during the entire test run.

- Alarm and fault conditions, such as force exceedance, were monitored continuously during operation so that the system could safely run unattended.

Since the deployed solution was an aerospace test system, the entire system underwent an extremely rigorous acceptance testing procedure to verify proper and safe operation.

| SOFTWARE FUNCTIONS |

|---|

| Arbitrary Load and Position Profiles |

| Flight Position Control |

| Load Position/Force Control |

| Endurance/Flight Schedule Execution |

| Deterministic RT for DAQ and PID Control |

| HARDWARE |

|---|

| PXI/SCXI Hybrid RT Chassis |

| Discrete Pump Skid Interface |

| Custom Control Panel/Console |

| INTERFACES |

|---|

| Ethernet TCP/IP |

| SCXI |

Results

Prior to deployment of our system, setup of a test was much more manual and operators needed to be around to monitor operation.

With our new system, complete endurance testing could be specified and executed with minimal supervision. Furthermore, the tight integration of real-time control, HIL testing, and coordinated data collection made report creation much simpler than before.

The rigorous acceptance test gave trustworthiness to the data and allowed the design engineers to validate performance more quickly than the prior semi-automatic and manual methods of operation.

Setup of tests has been improved from prior operations. The endurance testing itself operated over a huge number of cycles lasting weeks to months between scheduled lubrication and maintenance.

The deployed system measures performance during the entire testing, even between the scheduled downtime.

Industrial Embedded Equipment – Leak Tester

Industrial Embedded Equipment – Leak Tester

Shortened Product Development Cycle for Industrial Equipment – A Leak Tester

Background

Leak testing sounds simple. It seems like all you have to do is wait for the pressure (or vacuum) to drop by a detectable amount and estimate the leak rate based on the time it takes to reach that detected decrease. But, in an assembly line, it’s not, mostly due to the desire to do everything as quickly as possible.

Many manufactured products need to be tested for leaks to be sure they hold pressure or vacuum. Examples are fuel cells, braking systems, air bags, air conditioner components, balloon catheters, and so on. The list is almost endless.

Our client needed to develop a new leak tester with lower cost and more sensitivity and same small size.

Technical Highlights

The manufacturer wants the test to run as fast as possible – production volumes can’t tolerate a long wait to sense a leak. And, don’t forget, these products are not supposed to leak, so the “bad” ones leak very s-l-o-w-l-y. This is where the complexity in performing a leak test in a manufacturing environment arises.

The tester must be super-sensitive – to be able to sense a leak as soon as possible balanced by cost constraints and the need for the tester to be physically small so it fits on the production line

The tester needs to provide a solid user experience – so it needs to be robust and smart so the production test operator can just use it without hassle.

Challenges

Our client had been building commercial leak testers for many years. Their development tools were built on in-house hardware designs and a software library for making measurements and interacting with the operator via buttons and a display.

The typical development cycle extended to over 1 year and they wanted to shorten that development timeline by utilizing more Commercial Off The Shelf (COTS) components, especially since embedded controllers had improved dramatically over the recent years, and they did not sell a huge number of these specialized product per year. Put another way, they were looking for a supplier that would pay better attention to them since they were competing for responsiveness from say the microcontroller vendors when those vendors were used to customers purchasing 100s of thousands of microcontroller per year. They were ready for a change in design tools and subcomponent vendors.

Another issue was the need for extremely accurate pressure detection (so the leak test could be fast!). They wanted to go with COTS components, but they could not find a COTS detection system (sensor and digitizer combination) with enough accuracy and responsiveness. They needed a hybrid approach of COTS for the controller and custom for the signal conditioning and acquisition I/O.

Results

The prototype unit was designed, built, and ready for testing of the leak testing capability in about 2 months after the requirements were completed. The collapsed single-board solution was then designed, built, and unit tested about 1 ½ months later.

Leak Tester Sub-assembly and enclosure

The custom circuitry combined with some proprietary algorithms executed on the NI SOM RIO was able to measure with about 10 times better sensitivity than the previous generations. This sensitivity translated into faster leak measurement times – a real selling point to our customer’s customers.

The customer was ready to do their validation in about 4 months after we had the green light to build. The ready-to-go VERDI prototyping system was a huge time-saver.

Viewpoint’s Solution

We worked with our client to develop a system based on the NI RIO platform from National Instruments (NI). We initially considered the NI sbRIO but chose the NI SOM RIO (sbRIO-9651) because of its size and slightly lower costs.

NI SOM

After an initial review of the customer’s design goals and requirements, a concerted effort was spent to morph those goals and adjust those requirements by iterative discussion between both of our engineering teams. It was truly a collaborative requirements gathering and design activity. We brought our knowledge of the NI SOM RIO I/O and LabVIEW programmability capabilities and the customer shared their understanding of leak detection and their customer needs.

VERDI – Chassis with modules

Enter VERDI – Once the requirements and initial design were complete, we designed and built a custom A/D and signal conditioning circuit board that could interface with the NI SOM RIO. The initial version of this board was designed to connect to our VERDI prototyping system so we could rapidly validate the performance of the circuitry without needing to build the complete single-board system (with SOM and other circuitry all on one board).

After some tweaking to improve this custom circuitry, we essentially copied the board layout from all the necessary I/O (SOM controller board, digital I/O, display I/O, and the custom leak-detection circuitry onto a single-board system. This effort was reduced, since we had a large amount of ready-to-reuse hardware designs already developed for the VERDI prototyping system.

Industrial Embedded Monitoring – Remote Structural Health Monitoring using a cRIO

Industrial Embedded Monitoring – Remote Structural Health Monitoring

Using a cRIO to remotely assess structural health

By connecting these systems with a host PC, we can monitor continuous vibration activity and alarm conditions on a variety of structures despite inclement weather.

Challenge

Continuously monitoring the structural health of the Long Island Railroad (LIRR) Viaduct despite the relative inaccessibility of the structure.

Solution

Using CompactRIO, LabVIEW FPGA, and the LabVIEW Digital Filter Design Toolkit to measure the modal analysis of vibration data generated from ambient excitation, capture this data remotely, and analyze significant events.

Background

Engineers use structural vibrations to assess the conditions of many constructions and machines, including buildings, bridges, dams, towers, cranes, and mountings. Although we have had tools to monitor structural vibration for decades, these tools restrict data collection to short durations of high-fidelity waveforms or longer durations of summarized power in frequency band results. Many structures vibrate in meaningful ways only in the presence of ambient forces such as wind, vehicle activity, nearby construction, or random events such as earthquakes and tornados. Therefore, data collection needs to be active during these events.

Due to recent improvements in memory storage, processor speed, and wideband wireless communications technology, we can collect high-fidelity waveforms over long periods. We can also communicate to host PCs that aggregate structural vibration data across multiple collection locations, providing permanent data collection and superior analysis and reporting capabilities.

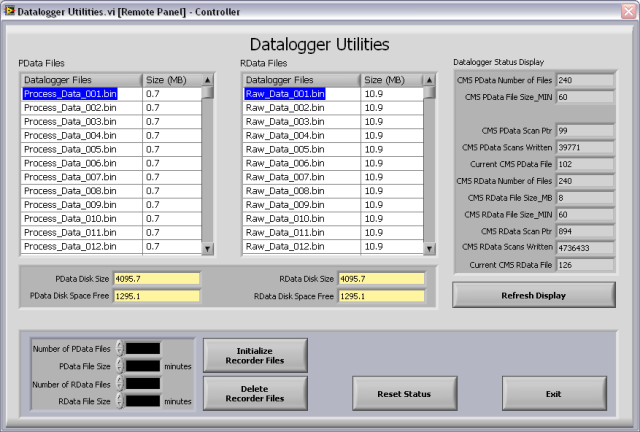

STRAAM Corporation, a leader in structural integrity assessment, and Viewpoint Systems, a Select National Instruments Alliance Partner, collaborated to develop a system that functions outdoors and in other less-accessible sites and maintains the capabilities of the available PC-based solution. Ultimately, we produced an enhanced version of STRAAM’s SKG CMS™ system to install on a Long Island railroad bridge.

System Requirements

The system needed to perform the following operations:

- Collect data from accelerometers and other environmental sensors

- Store weeks of data locally at full acquisition rates

- Analyze custom data in real time

- Publish summary statistics periodically to the host

- Upload waveforms to host on request

- Offer rugged, lightweight, cost-effective, reliable OEM deployment

- Contain flexible architecture to handle future capabilities

- Ensure secure user access control

System Design

We chose a system based on the NI CompactRIO platform and dynamic signal acquisition (DSA) C Series modules. The CompactRIO and associated C Series signal conditioning modules have an operating temperature range of -40 to 70 °C, well within typical environmental extremes for most installation locations. Additionally, the CompactRIO controller has no moving parts, increasing the mean time between failure and ensuring it can withstand physical mishandling during shipment and installation. For software, we decided to use the NI LabVIEW Real-Time Module and the LabVIEW FPGA Module. We used LabVIEW FPGA for basic signal acquisition as well as some custom antialiasing filtering to allow for sampling rates below the capabilities of the DSA module.

Figure 1 – Equipment mounted to LIRR Support Beam

Data Acquisition and Filtering

The DSA module acquired acceleration signals via special sensors, supplied by STRAAM, that output information about tilt and acceleration. Because large structures resonate at low frequencies, it is important that these sensors have extremely low noise, high dynamic range, and low frequency response to gather information about structures at less than 1 Hz. The low frequency range and long-term data storage need combine to create a maximum data collection rate frequency of 200 samples per second (S/s). The NI 9239 does not sample that slowly due to its delta-sigma converter technology, so we sampled at 2,000 S/s and used lowpass digital filtering on the field-programmable gate array (FPGA) to produce an antialiased signal at 200 S/s. Simple subsampling through decimation would violate the Nyquist criterion. Using the LabVIEW Digital Filter Design Toolkit, we produced a 28-tap infinite impulse response (IIR) filter with a 3 dB roll-off at 0.8 times the sample rate with a stopband attenuation greater than 90 dB. The Digital Filter Design Toolkit includes tools to automatically generate code to deploy the filter to the FPGA. We carefully selected fixed-point arithmetic to ensure proper operation without using excessive FPGA resources. The final filter was a 24-bit fixed-point solution with a 4-bit mantissa.

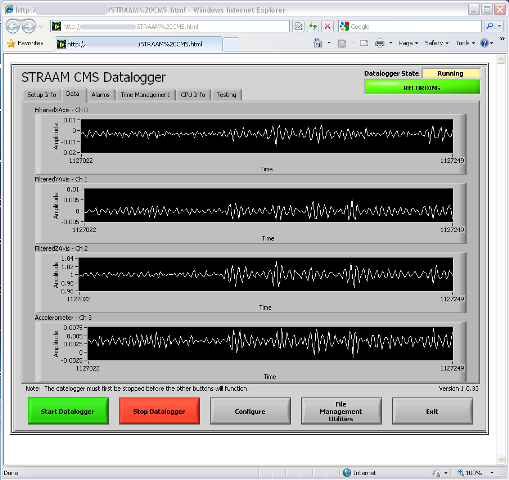

Figure 2: Remote Front Panel Displaying Acceleration Waveform Capture

Configuration, Signal Processing, and Alerts

STRAAM uses proprietary analysis routines, based on the structure’s resonant frequencies, to extract relevant information from the continuous stream of acceleration data. Because ambient energy excites the structures, we analyzed some initial data to locate these resonances. After this initial period, we configured the CompactRIO to perform the proprietary analyses based on the location of these resonances. We handled all activity in this initial setup remotely via wireless communications. We connect to CompactRIO over a wireless connection, then to a LabVIEW remote panel where we initially acquire and assign resonance bands.

The signal processing requires the spectral power and time-domain structure of the waveforms inside those resonant bands. The CompactRIO processor and FPGA module can calculate fast Fourier transform (FFT)-based power spectrums and perform time-domain filtering calculation so we can base calculations on the complicated algorithms provided by STRAAM. Furthermore, the large CompactRIO RAM can archive raw acceleration waveforms for later retrieval. The LabVIEW development environment greatly simplifies adjusting these calculations. We apply additional calculations to identify noteworthy events to alert the engineers when important conditions occur. These conditions may signify the presence of a meaningful ambient excitation or that considerable changes to the structure have occurred.

Host Communication

In order to successfully operate, this system needs to communicate effectively to the host PC. Because the system is deployed in almost-inaccessible and outdoor locations, all interactions with the system should occur remotely. Using cellular modems, the system connects via TCP/IP to upload important information, issue event alerts, and allow remote configuration. We designed the LabVIEW application to send periodic summary information via custom binary messages to the host with information about the condition of the structure and the CompactRIO system. The host then tallies this information along with all other SKG CMS™ systems deployed in the field. In addition to this summary information, the host can pull raw waveform data from the CompactRIO RAM. To avoid tampering and unauthorized access, we password protected all connections.

Figure 3 – Data File Configuration Screen

Summary

We have successfully installed several functional SKG CMS™ systems based on the CompactRIO platform. By connecting these systems with a host PC, we can monitor continuous vibration activity and alarm conditions on a variety of structures despite inclement weather. Our customers enjoy the benefits of modern Ethernet-driven, Web-based connectivity to verify the status of their structures and we enjoy the benefits of the rugged, reliable, low-cost, and reprogrammable CompactRIO system for data collection.

Digital Record And Playback – For a RF Receiver

Digital Record And Playback – For a RF Receiver

Collect hours of data at >1 GB/s

Client: A large high-tech R&D-oriented company.

Challenge

- Record hours of data at >1GB/s

- Play back digital test patterns for the RF receiver at real-time rates to understand bit-error rates

- Understand effects of RF chain prior to digitization

- Allow for platform to assist with algorithm development, debug and optimization

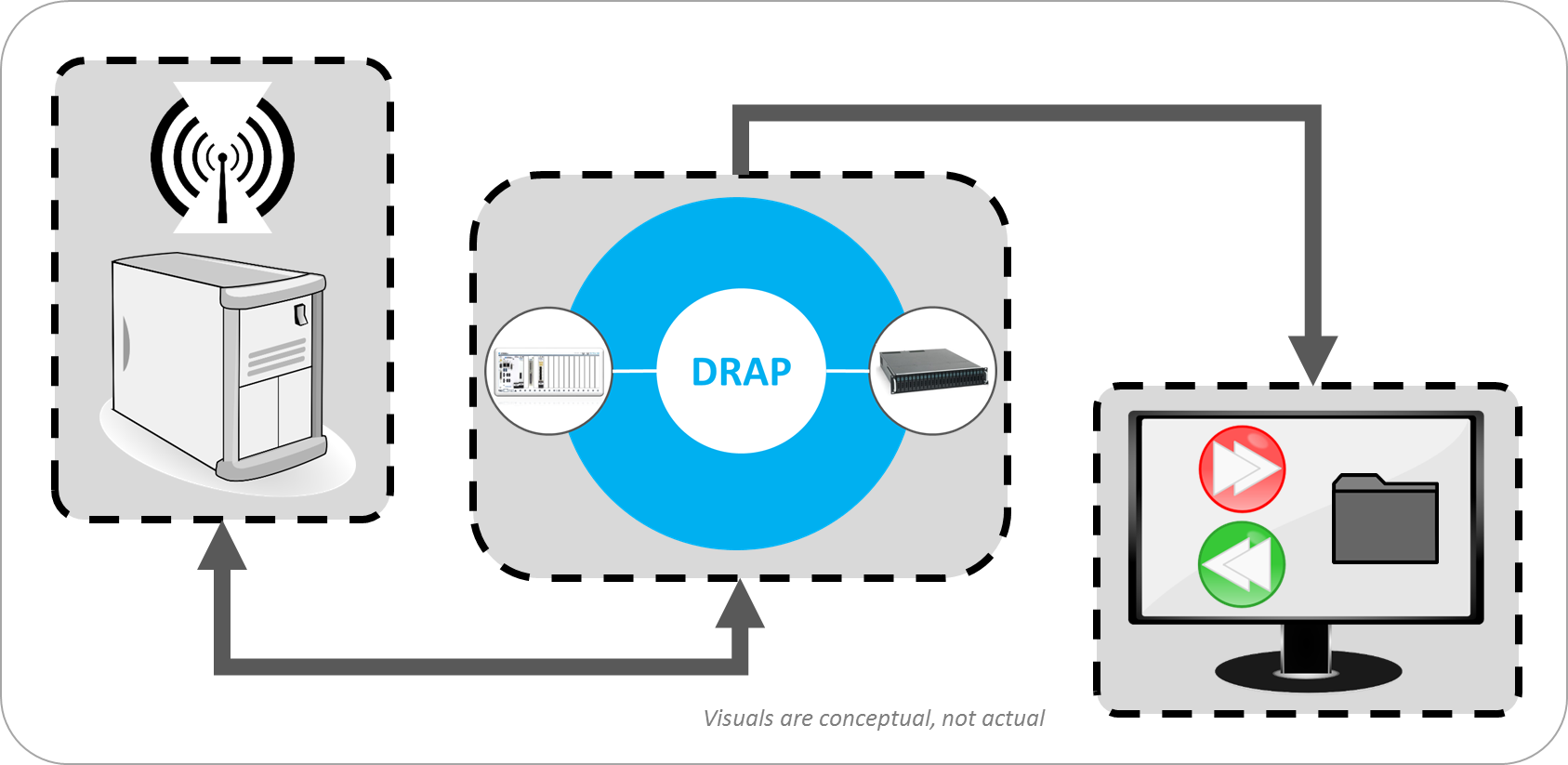

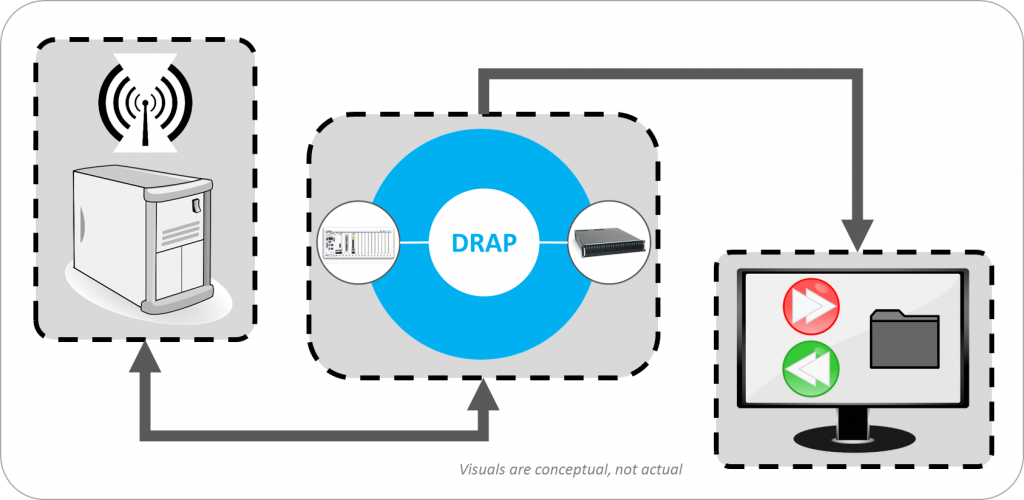

Solution

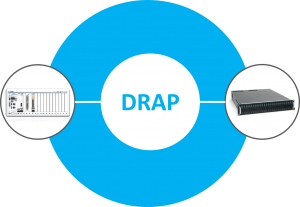

We utilized off-the-shelf hardware combined with custom software and had a working system after ~7 man-weeks of effort. The DRAP system records and plays back digital data only, with A/D conversion being handled by the DUT. The system was developed on the National Instruments PXI Express platform. A RAID array of disks is used to continuously record data. Data manipulation is performed on a Xilinx Kintex-7 FPGA that forms the basis of a National Instruments High Speed Serial board. The DRAP system is connected to the RF receiver using standard SFP+ connectors. A UI connects to the system locally or over Ethernet to monitor and control DRAP during record/playback. The customer can also control the system via an API so that it can be integrated into a larger test system.

Benefits

- Allows for repeatable data through the processing chain.

- Can re-sample data, inject new headers into data packets, and re-pack new data.

System Overview

Manufacturing Test System for Electrical Components

Manufacturing Test System for Electrical Components

Replacing Obsolete Custom Electronics with cRIOs in High-Power Capacitor Testing

Modular Embedded cRIO Systems Shortens Development and Reduces Risk in Complex PC-based Test System

Client: A major manufacturer of electrical power generation and distribution equipment.

Problem Scope

This project involved retrofitting a test system used to verify operation of a high-power capacitor used in electrical power distribution. This system was originally built around 1990. Critical sections of the original test system relied on custom, wire-wrapped analog and digital circuitry to process, analyze, and isolate the high-voltage and high-current signals created by the capacitor. Analog filters, rectifiers, and comparators produced pass/fail status signals. A master PC, other measurement and control equipment, the analog circuits, and a six-position carousel were integrated to create the entire automated test and control system.

For each unit under test (UUT), test specifications are obtained from a Manufacturing Execution System (MES) and cached locally. The subsystems at each carousel position are designed to run independently. This parallel capability allows greater throughput and reduced test time per capacitor unit. In addition, as different capacitor models move through the carousel stations, the test parameters and conditions must be aware of the particular model being tested.

Test results for UUT are pushed back to the MES system for record retention and data mining. The existing MES interfaces were retained exactly for the retrofit.

Challenge

All capacitors require 100% testing prior to shipment, so the test system is critical for the facility operation. Two or even three shifts are common depending on production needs and the facility cannot afford any significant downtime. Thus, a challenge was to design and build a test system that worked and was very robust.

Another huge challenge was the lack of documentation on the existing system, requiring a sizable amount of reverse engineering to understand the test system operation before development on the new system could begin.

Furthermore, one of the most important challenges surrounded replacement of substantial amounts of original test equipment before the new test equipment could be installed. Thus, we absolutely had to minimize the time and risk in this upgrade changeover.

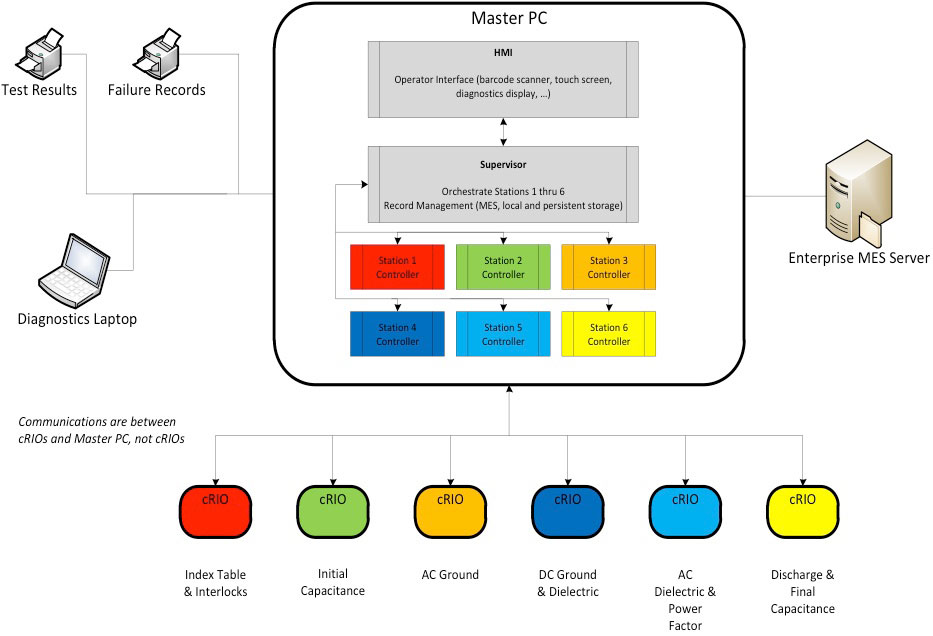

Technical Highlights

A schematic of the overall system architecture is shown in the figure. The major components of the system are:

- Master PC for supervisory control and test execution management

- NI cRIOs with FPGAs and Ethernet for independent yet PC-supervised operation

- Station-specific FPGA code for replacing wire-wrap circuitry functionality

- Integration with existing MES, safety equipment, tooling, and measurement hardware

The architecture chosen was made very modular by the capabilities offered by the cRIO. The Master PC interfaced with station-specific measurement instrumentation as needed, such as GPIB controlled equipment, and coordinated control and outcomes from the cRIOs. This additional equipment is not shown in the figure.

Solution

The Master PC coordinated all the activities including interfacing with the existing MES database and printers at the manufacturing facility. In addition, this PC provided the operator interface and, when needed, access to engineering screen on a diagnostic laptop.

The cRIOs were essential to the success of this test system. Each cRIO functioned as the equivalent of a high-speed standalone instrument.

The cRIOs at each carousel test position had to provide the following features:

- Digital I/O for machine feedback, safeties, and fault conditions

- State machines to coordinate with external commands and signals

- Perform numeric calculations to emulate the old analog circuitry

- Control loops for currents associated with voltages needed by different capacitors

- Communication support with the master PC

- Computation and detection of internal fault and UUT pass/fail conditions

We were able to duplicate the behavior of the wire-wrapped circuitry by converting the schematic diagrams of these circuits into FPGA code and then tweaking that code to mimicking the actual signals we measured with data acquisition equipment on the original test hardware.

The outputs of the circuitry were reconstructed on the FPGA with band-pass filtering, calibration compensation, point-to-point RMS, and phase & frequency functions. This functionality was implemented in fixed-point math and the 24-bit inputs on the A/D provided sufficient resolution and bandwidth for a faithful reproduction of the electronic circuitry. These embedded cRIOs provided a very effective solution to what otherwise might have required another set of costly and rigid custom circuits.

Finally, for optimizing the task of replacing the old equipment, we used a set of cRIOs, not shown in Figure 1, to provide Hardware-In-the-Loop (HIL) simulation of the manufacturing and measurement equipment. These cRIOs imitated the rest of the machine by providing inputs to and reacting to outputs from the embedded cRIO controllers, thus supporting comprehensive verification of the new test system before the tear-out of the existing hardware. Furthermore, these HIL cRIOs enabled fault injection for conditions that would have been difficult and possibly dangerous to create on the actual equipment.

How to select a LabVIEW consultant

Maybe you’re LabVIEW programmer quit or retired, or maybe you’ve got some internal capabilities but need some additional support because everyone’s too busy. From hourly rates to a range of skills, there are several factors to consider. We’ll help you weigh each one. See How to Select a LabView Consultant.

LabVIEW developers: local vs remote

Headquartered in Rochester NY, we help customers all over the U.S. See the Pros and Cons of a local vs remote supplier for LabVIEW-based test system development.

3,000+

LabVIEW solutions deliveredGreat for automated measurement & control: manufacturing test, product validation, machine control and condition monitoring.

700+

LabVIEW FPGA systems deliveredGreat for applications requiring seriously deterministic timing, reliable code execution, and multi-channel synchronized processing.

1,000+

LabVIEW RT systems deliveredThe combination of LabVIEW RT and the RTOS on which it runs allows for the creation of applications with bounded jitter and latency.

500+

cRIO-based systems deliveredCombining a cRIO controller with the multitude of C Series modules creates a functional real-time controller in a small footprint.

1,500+

PXI-based solutions deliveredBroad range of off-the-shelf expansion cards & processing horsepower make PXI a formidable choice for many automated test applications.