LabVIEW Consultants / LabVIEW Programming Services | LabVIEW System Integration

US-based manufacturers: Need a LabVIEW Expert?

Need some existing code updated? Need a whole new LabVIEW-based test system?

While we go by many names (e.g. LabVIEW experts, LabVIEW system integrators, LabVIEW consultants, LabVIEW specialists, LabVIEW programmers, LabVIEW developers), the key takeaway is that we can take the software development and hardware integration off your plate.

Capabilities & Expertise (LabVIEW and NI hardware related)

- LabVIEW-based automated test system development

Test system architectures including, as needed, state machines, actor framework, OOP, real-time on RT and FPGA, machine control, C#, and Python

- Agile Development (leveraging Microsoft Azure DevOps)

SVN & Git for source code control

LabVIEW data management

LabVIEW-based advanced test report development

LabVIEW-based remote access and remote monitoring

SQL database design and interfacing

Integrate with RESTful APIs in LabVIEW

Leverage gRPC Services in LabVIEW

Integrate .NET on CompactRIO

- Custom electronics design including signal conditioning

Communications using MIL-STD-1553, IEEE-1394b, and ARINC, Ethernet, gRPC, …

ITAR Registered

ISO 9001 certified

We have one or more:

Certified LabVIEW Architect

Certified LabVIEW Developer

Certified TestStand Architect

Talk to a LabVIEW Consultant. |

|---|

We’ve helped teams at some of the world’s most innovative companies

Testimonials

“Very impressed…kudos to Viewpoint”

I really want to thank you for all your help getting us to this stage in automating our testing. We had our customer in this week to oversee some testing and they were very impressed, which is definitely kudos to Viewpoint.

“Significant value”

The Viewpoint team provides significant value to our projects, and I really enjoy working with Viewpoint.

“Valuable part of our global team”

I have been working with Viewpoint for 15+ years on multiple projects. They have always provided creative and quick solutions to all of the problems we have placed in front of them. I have always considered them a valuable part of our global team.

LabVIEW Case Studies | Projects

Custom Test System Using NI PXI for Electrical Test

Custom Test System Using NI PXI for Electrical Test

Updating an obsolete tester that maintains functionality

Client – Medical Device Manufacturer

Challenge

Our client already had a test system in place, but the tester (really two test systems testing two different product variants) was becoming obsolete. The tester was old, hardware was failing, and it was getting harder and harder to keep it reliably running. They wanted a new tester to improve reliability, but maintain the functionality of the existing tester to keep the FDA-mandated verification and validation time to a minimum.

Solution

The updated end-of-line manufacturing test system maintains the functionality of the old test systems, but with updated hardware and software. The same software is utilized for both the manual test system update and the automated test system update. Our client deployed 6 manual testers and 1 automated tester.

Benefits

- Improved maintainability and reliability with updated hardware and software

- Maintains existing test system functionality to keep certification time down

System Overview

There were two variants of the new test system. One was for an older product line that utilized manual test, with an operator that connected/disconnected the UUT, and initiated the test. The other was an automated tester, integrated into a manufacturing machine. Both testers utilized custom fixtures (provided by the client), off-the-shelf NI measurement hardware (selected by Viewpoint), and custom test software (developed by Viewpoint). The software is configurable for both the manual test system and the automated test system.

| SOFTWARE FUNCTIONS |

|---|

| Read UUT limits from config file |

| Perform tester self-test |

| Measure impedance |

| Power UUT |

| Pressurize UUT |

| Measure UUT output |

| Perform leak down pressure test |

| PLC interface (for automated tester) for start, done, pass, fail |

| HARDWARE USED |

|---|

| Custom test fixture (provided by client) |

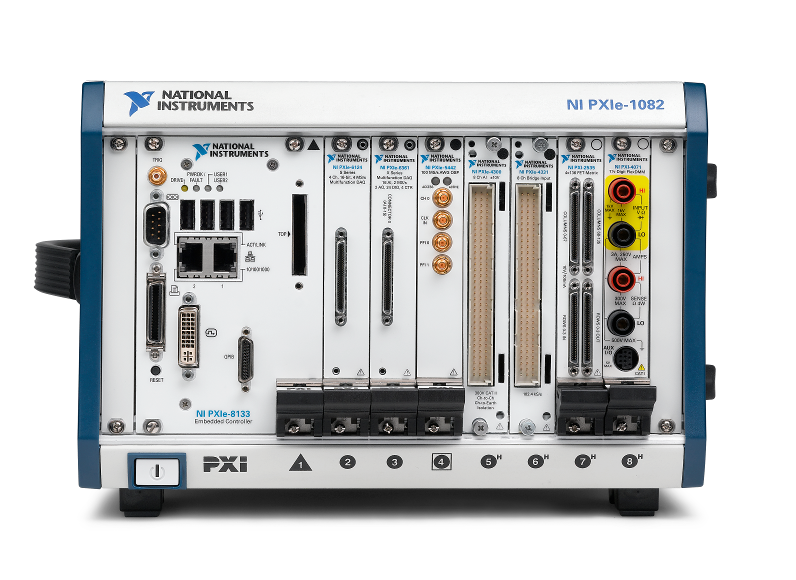

| NI PXI |

| PXI Multifunction I/O Module |

| PXI Digital I/O Module |

| PXI Relay Module |

| PXI Digital Multimeter Module |

| PXI Switch Matrix Module |

*- images are conceptual, not actual

Manufacturing Inspection System Uses Machine Vision to verify assembly and labeling

Manufacturing Inspection System Uses Machine Vision to verify assembly and labeling

Reducing human error with automated inspection

Client – Automotive Component Manufacturer

Challenge

Our client already had an end-of-line tester in place. However, preventing incorrect product shipments drove them to add machine vision capabilities to verify that the part being packed is of the correct physical configuration and that the part was labeled correctly. They also wanted a more automated way to track which serial numbers were being shipped.

Solution

Viewpoint enhanced the existing end-of-line tester by adding machine vision capabilities to verify correct part assembly and part labeling. This capability also allowed for automated tracking of which parts went into which shipping container.

Benefits

- Automated part assembly verification to reduce human error from manual visual inspection

- Automated label verification to reduce the chance of shipping the wrong product

System Overview

The enhanced system added machine vision-based capabilities to an existing end-of-line manufacturing test system. New hardware (cameras, lighting, fixture) was selected and integrated by the client. Viewpoint developed the image analysis routines using the Cognex In-Sight software. These routines were then downloaded and controlled using LabVIEW software developed by Viewpoint. In addition, the LabVIEW GUI contained the image acquired by the camera and the results of the image analysis. The tester can inspect four different part types.

The software essentially performs the following functions:

- Look up the expected characteristics of the part being inspected.

- Populate the on-camera In-Sight “spreadsheet” with configuration information used in the image analysis/inspection.

- Trigger the image capture and read results from the on-camera spreadsheet.

- Use the on-camera image analysis to check a critical angle of the part as the part is set in the nest fixture.

- Check the information laser etched on the part and compare the results with what should be on the part (relative to the barcode read in for the lot and the 2D barcode on the part) using the OCR/OCV capabilities of the camera.

- Perform other physical part characterization image analyses to verify the part was correctly labeled & assembled.

| SOFTWARE FUNCTIONS |

|---|

| Look up expected part characteristics |

| Trigger image capture |

| Read results of on-camera image analysis |

| Display image taken by camera and show if test passed or failed |

| Monitor contiguous part failures & initiate shutdown |

| Log vision test failures to database |

| HARDWARE USED |

|---|

| Existing end-of-line tester |

| Test Fixture |

| (qty 2) Cognex camera |

| Lighting for camera |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

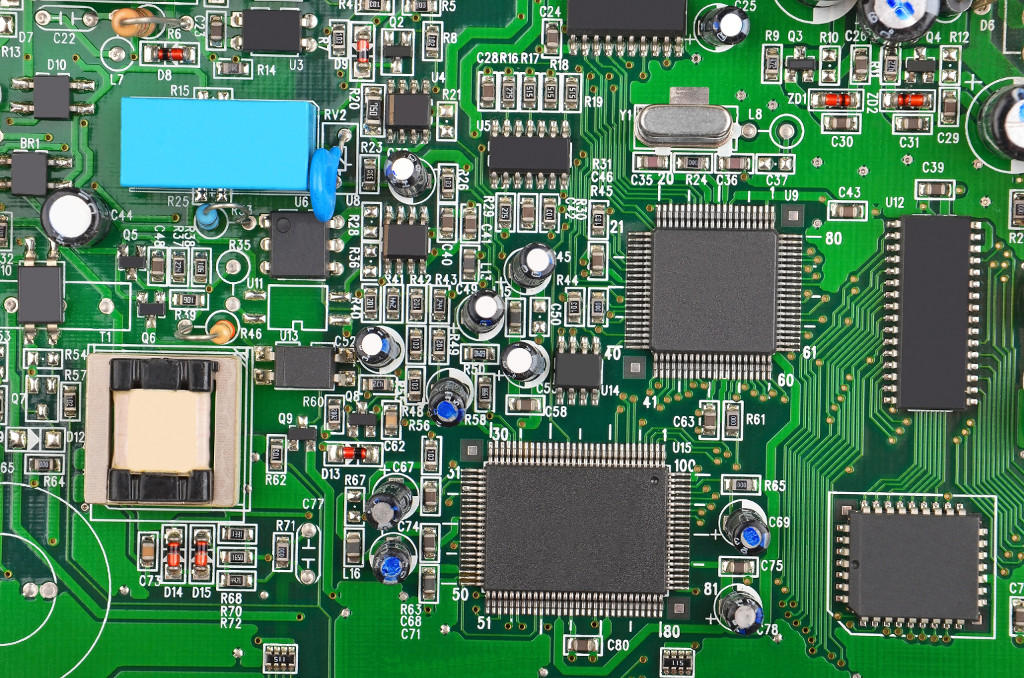

Automated Manufacturing Test System for Electronic Medical Devices

Automated Manufacturing Test System for Electronic Medical Devices

Using PXI and LabVIEW for modular testing of over 1,000 different models

Client – a medical device manufacturer and repair depot

Challenge

Our client manufactures hospital patient pendants used to control bed frame, nurse calling, and TV functions. The company was also growing after adapting a business model of being a repair depot for older designs for their own and the pendants of other manufacturers. As such, their products are very high mix and medium volume.

The basic functions for all these pendant models are closely related, so the client wanted a means to build a single automated test system that could verify functionality for 1000s of models. And, since the products are medical devices, the testers needed to comply to 21 CFR Part 820 and Part 11.

Solution

The testers were designed to support the common measurements needed to test the circuitry of the devices as well as the complex signals required to drive TVs and entertainment systems. A test sequence editor was created which allowed the client to create as many test sequences as needed to test each specific pendant model by creating a list from pre-defined basic measurement steps configured for each specific measurement.

For example, each device had a power supply, the voltage of which needed to be tested. To test a specific model, a voltage measurement step was added to the model-specific sequence and configured with the upper and lower measurement limits for the power supply. The complete test sequence was created by adding and configuring other measurements test steps as needed. Each test step could also be configured with switch configurations to connect the measurement equipment, such as a DMM, to the proper pins on the device circuit board.

Using this configuration process, the client was able to support the testing of well over 1000 models without any programming. A separate application was developed to create these test sequences which were saved as XML and fed to the test system for selection and execution.

The test execution was managed by NI TestStand and the pre-defined common test steps were written in LabVIEW. The test sequences and test results were interfaced to the client SQL database which they used in their ERP system. This ERP system used the results produced by the test system to help manage the workflow of production, for example by assuring that all units had passed testing before being shipped. Part 11 compliance was handled through checksums used to check if results had been modified.

Benefits

- Test sequence editor used to develop and maintain tests for 1000s of device models

- Enabling our client to create test sequences without programming reduced overall development costs by about 50%.

- Test sequences and test results were stored in the client’s ERP SQL-compliant database for integration with manufacturing workflow

- Modular and common software developed for the test systems reduced the V&V effort during IQ & OQ by allowing testing of the test execution application separate from the individual test sequences.

System Overview

The automated test system was able to execute each test sequence in three different modes: engineering, service, and production. Each mode has been specifically designed for various departments throughout the manufacturing floor. Typically, the manufacturing engineer would verify the sequence by executing it in engineering mode. Once the test sequence parameters pass, it was then approved for production testing.

During actual product testing, an approved and digitally-signed test sequence is loaded and executed via the test sequencer, designed for automated production. During execution, test results are displayed to the operator and simultaneously pushed to a database. The automated test system produces a record for each tested device, indicating the disposition of each test step and the overall performance of the device. All result data are digitally signed and protected from tampering.

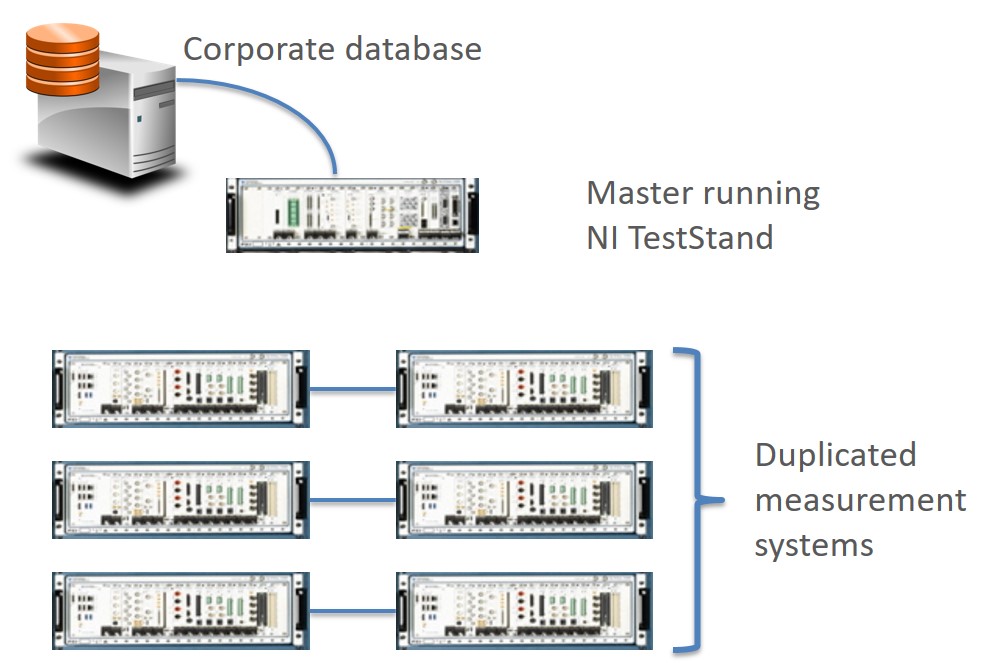

The architecture of the test system follows a typical client – server model.

All client stations communicate with a central ERP and SQL server and each computer is secured by applying operating system security. The SQL server contains all of the test definitions, device history records and results. Information from it can be queried at any time by quality engineers throughout the organization, assuming they have proper login access. This provides real time status about products ready for shipment. Also, other than the software running on the client stations, no other user has permission to write or modify any information in this database. The client is able to keep the server in a protected area separating it from the manufacturing environment while the client test stations are placed throughout the manufacturing area.

Surprisingly, there were only twelve test steps needed to uniquely configure and be combined to create sequences to test well over 2000 unique models. Test steps are capable of measuring basic resistance, current and voltage parameters as well as perform sound quality measurements and high speed digital waveform analysis. Several tests were designed to be subjective while others are fully automated and test to a specified acceptable tolerance. During configuration, each test step requires the manufacturing engineer to enter expected values and tolerance limits to define pass – fail status. Upon testing, the devices are attached to a generic interface connection box and the test system makes the appropriate connections and measurements.

| SOFTWARE FUNCTIONS |

|---|

| NI TestStand |

| Low-level measurement drivers to interface to a DMM, signal generator, switches, and data acquisition cards. |

| Measurement-based test steps |

| Test sequence execution |

| Test sequence management |

| User access management |

| Test report creation and management |

| Verification of test sequence content and ability of user to execute |

| Verification of the content of the test results |

| HARDWARE USED |

|---|

| NI PXI chassis and controller |

| NI PXI acquisition cards for analog measurements |

| NI PXI acquisition cards for digital input and output |

| NI PXI DMM for precision voltage and resistance measurements |

| Audio amplifier for speaker tests |

| INTERFACES / PROTOCOLS |

|---|

| Ethernet |

*- images are conceptual, not actual

Automated Manufacturing Test Systems for Medical Diagnostic Equipment

Automated Manufacturing Test Systems for Medical Diagnostic Equipment

Using NI PXI and LabVIEW as a common architecture for multiple test systems testing several subassemblies

Client: a manufacturer of automated blood analysis machines

Challenge

Our client was embarking on a complete redesign of their flagship automated in-vitro Class 1 blood diagnostic machine. In order to meet schedule goals, the design and build of several automated test systems needed to occur in parallel with the overall machine. In a major design paradigm shift, many components of the machine were being manufactured as modular subassemblies, every one of which was an electro-mechanical device. Thus, multiple testers were required to test each of the specific subassemblies in the machine. And, since this was a medical device, the testers needed to comply to 21 CFR Part 820 and Part 11.

Solution

With a looming deadline, the testers needed a common architecture, so that all testers could leverage the development from the others. Since each subassembly could be tested independently of the overall machine prior to final assembly, the design of the testers was based on a common measurement and reporting architecture, written in LabVIEW, that interfaced to the customers Part 11 compliant database for testing procedures and measurement results. Furthermore, procedures and validation checks for calibration of the testers were part of the overall test architecture.

Benefits

- Modularization of the test system architecture aided development and maintenance

- Reduced overall development costs due to standardization of test sequence steps and reporting

- Both test sequences and test results were stored in a managed database that satisfied 21 CFR Part 11 requirements

- Modular and common software developed for the test systems reduced the V&V effort during IQ & OQ.

System Overview

Since multiple subassemblies were being tested, with one part-specific test system per part, the automated test systems used as much common hardware as possible to simplify the development effort through common hardware drivers and test steps. Measurements were made with PXI equipment. Test steps and the test executive that executed the test sequence(s) were developed using LabVIEW.

The types of test steps required to verify the proper operation of each subassembly were categorized into basic operations, such as voltage reading, pulse counting, temperature reading, and communications with on-board microcontrollers. The specifics of each measurement could be configured for each of these measurement types so that each test step accommodated the needs of the specifics of each subassembly. For example, one subassembly might have needed to run the pulse counting for 2 seconds to accumulate enough pulses for accurate RPM calculation while another subassembly might have only needed 0.5 seconds to accomplish that calculation.

The configuration of a test step algorithm was accomplished via an XML description. The accumulation of these XML descriptions of each test step defined the test sequence run on that specific subassembly.

Test results were associated with these test sequences by completing the entries initially left blank in the test sequence, so that all results were explicitly bound to the test sequence.

The operator user interface distinguished between released and unreleased test sequences. With unreleased test sequences, engineers could try the most recent subassembly designs without needing to wait for final validation. The released sequences were only available to test operators. This login-driven branching was managed using the Windows login, so that the client employees could use their company badge-driven login process. Once logged in, the user would be able to execute the test sequence in automated mode, where all steps happen automatically, or manual mode, where one step could be operated at a time.

Furthermore, the Windows environment was locked down using built-in user account group policies to designate the level at which a user could access Windows or be locked into accessing only the test application.

V&V Effort

During the V&V effort, each test sequence was verified for expected operation, against both known good and bad parts. Once verified, the sequence was validated against the requirements and, when assured to be as expected, a checksum was applied to the resulting XML test sequence file and all was saved in a Part 11 compliant database. Upon retrieval, when ready to run a test, the sequence was checked against this checksum to assure that a sequence had not been tampered.

Test results, saved as XML in the same file format as the test sequence, were also surrounded by a checksum to verify that no tampering had occurred.

The IQ/OQ efforts were handled in a traditional manner with the client developing the IQ/OQ documentation, with our assistance, and then executing these procedures, again with our assistance.

| SOFTWARE FUNCTIONS |

|---|

| Low-level measurement drivers |

| Measurement-based test steps |

| Test sequence execution |

| Test sequence management |

| User access management |

| Test report creation and management |

| Verification of test sequence content and ability of user to execute |

| Verification of the content of the test results |

| HARDWARE USED |

|---|

| PXI chassis and controller |

| PXI acquisition cards for analog measurements |

| PXI acquisition cards for digital input and output |

| CAN card |

| INTERFACES / PROTOCOLS |

|---|

| Ethernet |

| CAN |

*- images are conceptual, not actual

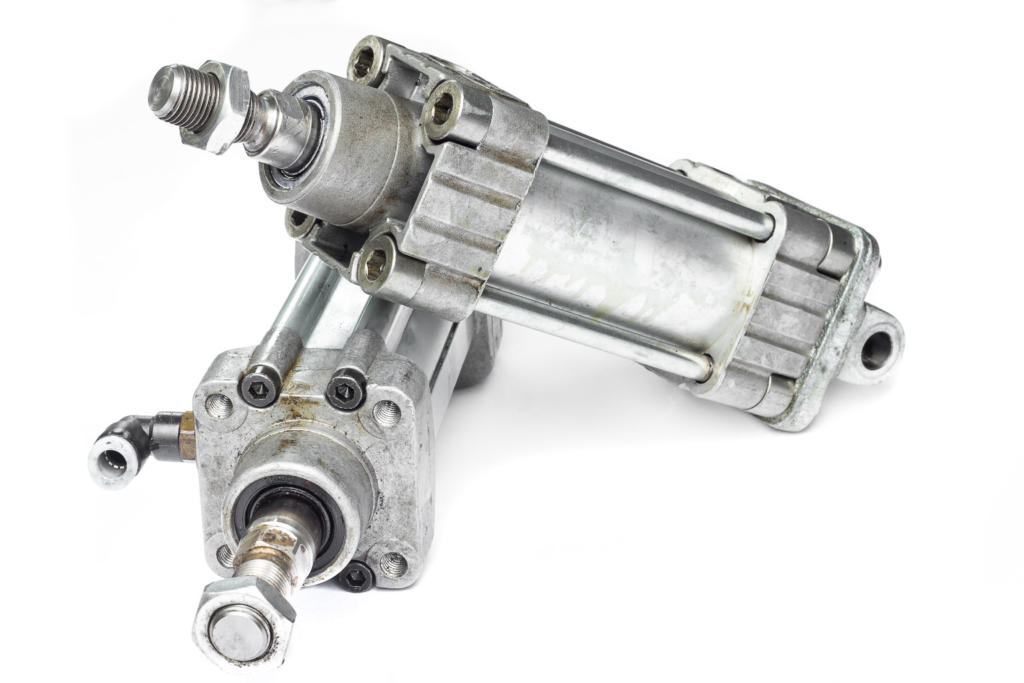

Endurance and Environmental automated test system for electro-mechanical sub-system

(image is representative, not actual)

Endurance and Environmental automated test system for electro-mechanical sub-system

Automating tests that run for weeks at a time

Client – Automotive component supplier

Challenge

Our client was already doing validation, but it was manual, and the client’s customer started requesting faster turnaround of results. Their customer was also requesting data to be sent with the results. Our client chose to automate the validation process to enhance their productivity.

Solution

Viewpoint utilized the (mostly) existing hardware from the manual tester and developed software to automate the testing. The LabVIEW-based automated test system allows for endurance & environmental validation testing of an electro-mechanical sub-system.

Benefits

- Automates tests that run for weeks at a time

- Logs errors during the test (e.g., for continuous monitoring tests, logging the number of instances of when a UUT’s LIN (Local Interconnect Network) response deviates from a static, current draw outside of limits)

- Capable of testing a large variety of product lines

- Logs pertinent data to a database for post-test analysis/inclusion into reports

System Overview

The UUT is an electro-mechanical part that falls under a variety of different product lines. As such, the client had a couple variants of the tester, based on the communication needs of the UUT. A total of more than a dozen testers were deployed. The functionality of the tester evolved over time, specifically modifying software to make the tests faster / decrease cycle time.

| SOFTWARE FUNCTIONS |

|---|

| Extensive diagnostic/manual operation of system for debug of software and electrical connections between the UUT and the test stand/tooling. |

| Product-specific software components to operate unique products. |

| Execute mechanical endurance tests. |

| Execute environmental endurance tests. |

| Database output containing results from every test cycle (either mechanical cycles or time depending on test being run). |

| HARDWARE USED |

|---|

| USB-LIN module |

| USB and PCI CAN Interfaces |

| Analog input card |

| Digital Input card |

| Digital Output card |

| Power Supplies |

| DMMs |

| Switch Matrix |

| INTERFACES / PROTOCOLS |

|---|

| CAN |

| LIN |

| USB |

| GPIB |

Product Validation of Mechanical Subsystem with NI cDAQ

Product Validation of Mechanical Subsystem with NI cDAQ

The updated product validation tester automates long tests, allowing the client to prove more obviously that their part met the specification.

Client – Automotive Component Supplier / Manufacturer

Challenge

The client already had a test system in place, but it was old and was becoming unmaintainable. Increasing demands from the test engineers and the old software architecture not lending itself to clean implementation of these new features (new sequencer capabilities and ECU CAN communication) drove the need for a rewrite of the software application.

Solution

The updated product validation tester supports product validation of the UUT by automating long tests (sometimes a week or more) providing the desired set point control, allowing the client to prove more obviously that their part met the stated specification. Viewpoint developed the software and the client selected the hardware.

Benefits

- Automate long duration tests

- Improved operator UX by making controls and indicators more intuitive to the user as well as providing additional capability within one application.

- Acquire ECU data along with measured UUT data to allow for engineering performance characterization analysis

- Playback utility enables the Test Engineer to quickly view collected data to chart out a path forward for further testing.

- Automate a Design of Experiments matrix of conditions, through new sequencer capabilities, to more quickly arrive at product characterization parameters.

- All collected signals are now housed in one TDMS file instead of multiple files from different applications.

System Overview

The UUT is a complete engine with a focus on one of the mechanical subsystems. Data is collected on over 100 channels, measuring temperature, vibration, strain, RPM, position and pressure. Engine management data (e.g., component location, pressures, engine speed, and status flags) is collected via CAN. The engine speed is set via an analog output, and subsystem setpoints are sent to the ECU via CAN. SCXI still used on some of the old test stands, but is being phased out in favor of cDAQ. The test system software was developed in LabVIEW.

| SOFTWARE FUNCTIONS |

|---|

| Test Sequencing |

| Data Visualization |

| Data Collection |

| Setpoint Control |

| HARDWARE USED |

|---|

| NI cDAQ |

| NI C Series Digital input module |

| NI C Series Digital output module |

| NI C Series Digital input/output module |

| NI C Series analog output module |

| NI C Series temperature input module |

| NI C Series analog input module |

| NI C Series strain/bridge module |

| INTERFACES / PROTOCOLS |

|---|

| Ethernet (TCP) |

| CAN |

LabVIEW-based Data Logger for Product Validation of Commercial Equipment

LabVIEW-based Data Logger for Product Validation of Commercial Equipment

Synchronizing data from multiple data logging instruments

Client – Manufacturer of commercial equipment

Challenge

The client already had a method in place to log data needed for validation testing. However, this data was acquired from multiple independent data logging applications. They needed something to aggregate the data and align/synchronize the data across multiple instruments.

Solution

Viewpoint developed a LabVIEW-based product validation solution that continued to utilize the existing data logging hardware, but uses software to aggregate & synchronize the data from multiple sources. This simplifies post-processing.

Benefits

- Synchronized & aggregated data from multiple instruments

- Ability to add capability for new instruments later on

- Real time graphing of all channels

- Channel averaging across multiple instruments

- Ability to save data acquisition configurations for future use

- Faster channel configuration than current data logging applications

System Overview

The data logging software unifies the collection of data for a particular validation test. The software configures each instrument, kicks them off, logs the data to a TDMS file, and also graphs data and displays real-time values.

| SOFTWARE FUNCTIONS |

|---|

| Instrument configuration |

| GUI |

| Data Acquisition |

| Data Synchronization |

| Data Logging |

| Multi-channel averaging |

| HARDWARE USED |

|---|

| Keysight Data Logger |

| Fluke Data Acquisition DMM |

| INTERFACES / PROTOCOLS |

|---|

| RS-232 |

| USB |

| Ethernet |

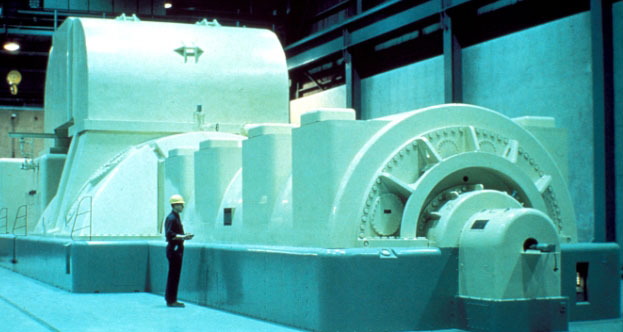

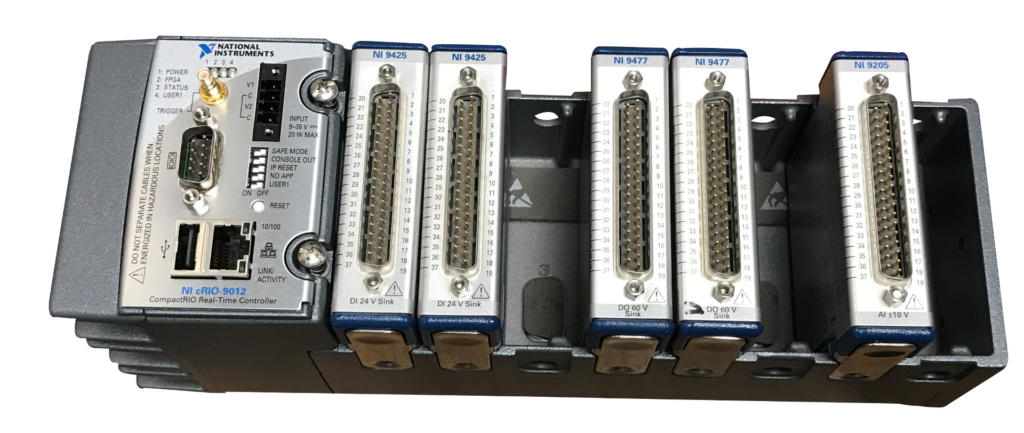

Online Monitoring of Industrial Equipment using NI CompactRIO

Online Monitoring of Industrial Equipment using NI CompactRIO

Improving Maintenance of expensive industrial equipment

Client – Large Industrial Equipment Manufacturer

Challenge

The maintenance of the equipment was not always done at the prescribed intervals because the cost of shutting down the plant is significant. This sometimes resulted in an equipment failure. This particular application is for equipment/machinery in the energy/power industry (a generator).

Solution

The online monitoring system monitors a particular parameter of interest to send warnings and alarms to the control room so that the operators know when maintenance needs to be performed on the particular part of interest. This system has been installed in multiple plants.

Benefits

- Enables condition-influenced maintenance intervals vs periodic intervals

- Reduces probability of catastrophic failure by providing warning indicator

System Overview

The system monitors the generator collector health. NI-based data acquisition hardware acquires the signal of interest, logs the raw data, processes the parameter of interest, and triggers/sends warnings and alarms to the control room. LabVIEW FPGA was used for analog and digital IO and a sensor check. LabVIEW Real Time was used for the calculation, data logging, serving data to the HMI and alarm/warning checking.

| SOFTWARE FUNCTIONS |

|---|

| Touchscreen GUI for data/alarm display and system configuration |

| Data logging |

| Signal processing and alarming |

| HARDWARE USED (selected by customer) |

|---|

| NI cRIO |

| NI Touch Panel Computer |

| Multiple NI C Series Modules |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

*- images are representative, not actual

Endurance Testing using NI PXI

Endurance Testing using NI PXI

An automated system permits faster validation, unattended test, an increase in throughput, and can free up resources for other tasks during the weeks long endurance test.

Client – A manufacturer of aircraft components in the mil-aero industry

Challenge

New product development drove the need for a new aerospace endurance test system for product validation. The old systems were not designed to test the newly designed part (aircraft actuators), and the company didn’t have the time or resources to reconfigure existing systems to perform the testing required.

Solution

The new PXI-based endurance test system provides automated electromechanical testing, full data recording, report generation and a diagnostic panel for intelligent debug. Viewpoint selected the NI equipment, while the test consoles, and other components were selected and fabricated by the customer.

Benefits

- This automated aerospace test system permits faster validation, unattended test, an increase in throughput, and can free up resources for other tasks during the weeks long endurance test.

- Full data recording with a data viewer enables post analysis, which provides the ability to review and analyze raw signals captured during execution. Channel examples are actuator LVDT position, load, current, and encoder actuator position.

- Summary report capability allows the customer to document the amount of testing completed against the full endurance test schedules.

- A manual diagnostic operational panel provides the ability to verify particular DUT functionality or components without running an entire schedule.

- Systems can be paused and restarted to allow for “scheduled maintenance” of the DUT such as inspections, lubrication, etc.

System Overview

The PXI-based aerospace endurance test system enables data collection, deterministic PID Loop Control, emergency shutdown and a diagnostic panel for manual test and debug operation. The system runs endurance test schedules, that are defined as a recipe for test execution. These schedules, which are customer-defined and DUT-specific, are designed to simulate the actual conditions the DUT would see in real world application as closely as possible. LabVIEW-RT was used for the deterministic looping for Closed Loop Control of Actuator Position and Load Control. LVDT demodulation was performed on a PXI FPGA card programmed with LabVIEW FPGA.

| SOFTWARE FUNCTIONS |

|---|

| GUI |

| Summary Reports |

| Full Data Collection for Real-Time and Post Analysis |

| Deterministic PID Loop Control |

| E-Stop Management |

| Diagnostics Panel for Manual Test and Debug |

| Endurance Test Schedule Execution |

| Hydraulic Control Panel for Source & Load PSI Control |

| HARDWARE USED |

|---|

| PXI |

| Various PXI-based Data Acquisition Cards |

| PXI RT Controller |

| PXI FPGA Card |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

Endurance Tester for Mission-Critical Mechanical Component using NI cRIO

Endurance Tester for Mission-Critical Mechanical Aerospace Component using NI cRIO

Ability to run tests unattended and overnight reduces operator labor and compresses test schedules

Client – Major Aerospace Component Supplier / Manufacturer

Challenge

The client had an older VB & PLC-based aerospace test system in place already, but it was obsolete. A new endurance test system needed to be developed to validate prototyped components (in this case, aircraft & aerospace bearings). Many of the prototypes are one-off, so it was important that the test system not destroy the component.

Solution

A new endurance test system was developed to validate prototyped aerospace components. The test system can be configured for automatic shutdowns so as not to destroy the component under test in the event of unexpected performance of electro-mechanical subsystem components. The updated endurance tester supports product validation by allowing the product to run under various test conditions (e.g. speed, load, oil flow, temperature) and collecting data for analysis.

Viewpoint developed the software and selected the NI hardware (other hardware was selected by the client).

Benefits

Ability to run tests unattended and overnight eases operator labor and compresses test schedules

Data collection allows for offline engineering analysis

Automatic shutdowns reduce destruction of the prototype component under test

System Overview

The updated cRIO-based endurance tester incorporates configurable profiles, data logging, and automatic shutdown to allow for safer extended validation testing. LabVIEW FPGA and LabVIEW RT were used together to interface with the test hardware sensors and controls. LabVIEW as used create the HMI for the test system.

| SOFTWARE FUNCTIONS |

|---|

| Closed loop control of bearing test oil flow |

| Axial load control |

| Driver for Emerson VFD |

| E-Stop and safety management (shutdowns based on alarm limits) |

| Data collection – temperature, pressure, flow, vibration, frequency |

| Operator/Diagnostic GUI for control of system |

| HARDWARE USED |

|---|

| NI CompactRIO (cRIO) |

| NI C Series Current Input Module |

| NI C Series Voltage Input Module |

| NI C Series Temperature Input Module |

| NI C Series Current Output Module |

| NI C Series Analog Input Module |

| NI C Series Sound and Vibration Input Module |

| NI C Series Digital Module |

| Emerson VFD (Variable Frequency Drive) |

| INTERFACES / PROTOCOLS |

|---|

| TCP/IP |

| TCP Modbus |

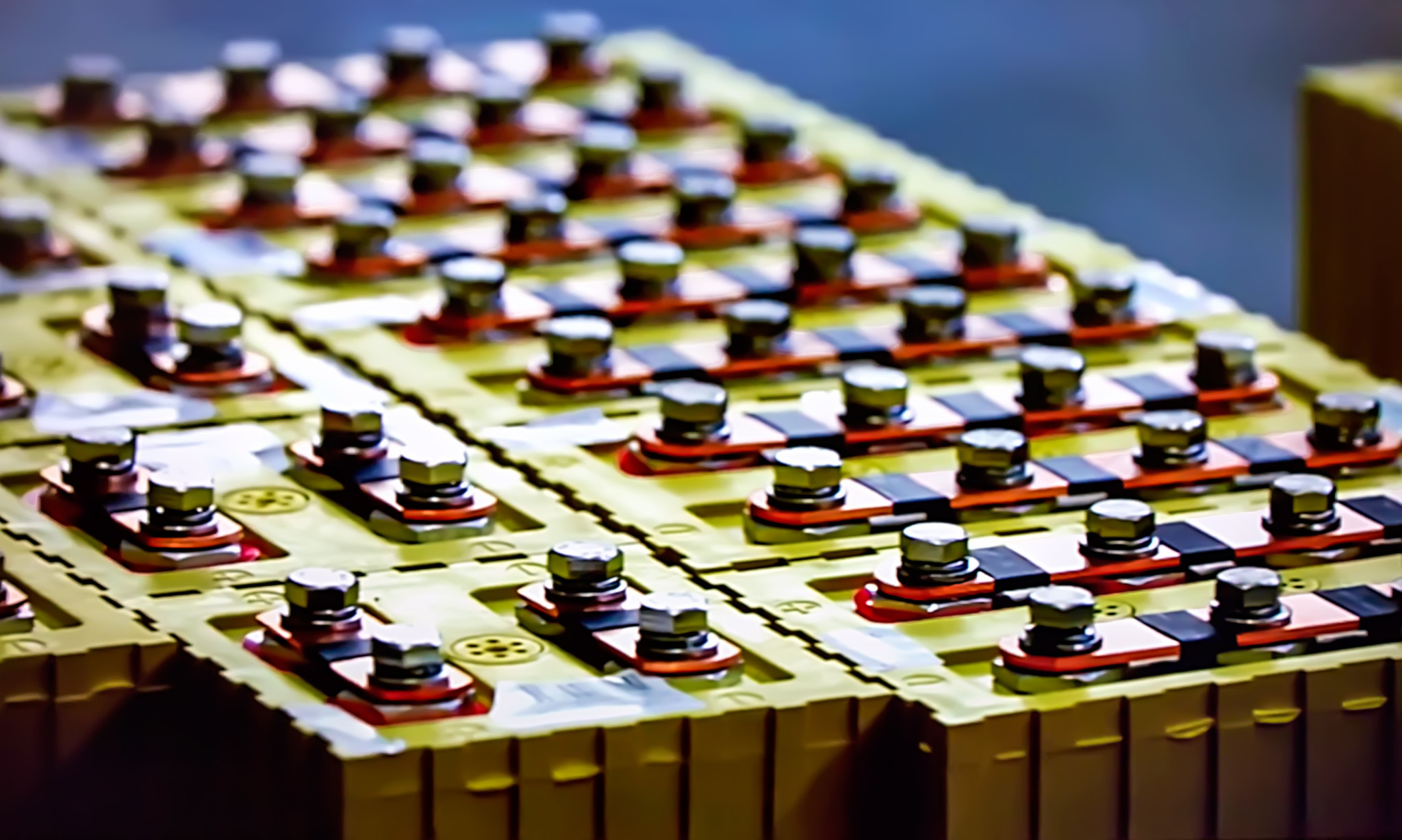

Industrial Automation – Improving Manufacturing Process with a semi-automated welder

Industrial Automation – Improving Manufacturing Process with a semi-automated welder

Automating a battery welder to improve consistency and increase throughput

Client

Industrial manufacturer of battery stacks

Challenge

The previous welding method was all manual, prone to errors and inconsistency. The old system also required the operator be in contact with the module while welding without any safety shielding.

Solution

The welder semi-automates the ultrasonic welding of terminals on a battery module as part of the manufacturing process. It allows for welds to be conducted in the same place for every module, reducing variability and operator errors. This system is also quicker than doing the welds manually.

Benefits

- Increased weld consistency

- Improved operator safety

- Increased welder throughput

System Overview

The system semi-automates the ultrasonic welding of terminals on a battery module. The system consists of an ultrasonic welder, XYZ table, and safety interlocks. The table moves the battery module to the correct welding position. Once in position, the Z portion of the table lowers the welder to the correct welding height. The application sends the signal to the welder to conduct the weld. Weld data is saved to a file from the welder Ethernet interface for later analysis. Viewpoint provided the software for this system, while the client provided the hardware for us to interface with.

Considerable attention was paid to addressing faults in the production process to avoid damage to the operator and the battery module during the welding process, due to the high current output available from the battery module.

| SOFTWARE FUNCTIONS |

|---|

| Welding routing configuration |

| Operator GUI |

| Maintenance mode |

| Interface to welder |

| Interface to table & controller |

| Interface to E-Stop & interlocks |

| INTERFACES / PROTOCOLS |

|---|

| RS-485 |

| Ethernet |

| 24V Digital IO |

Endurance Tester using NI cRIO

Endurance Tester using NI cRIO

Multiple International Deployments Helps Prove Product Meets Spec.

Each endurance test can run upwards of 6 months.

Client: Major Automotive Component Supplier

Challenge

A new endurance test system was developed to give more precision in the control setpoint. This additional precision enabled potential clients to review the product performance in real-life situations. Each endurance test can run upwards of 6 months.

Solution

The updated endurance tester supports product validation by providing the desired parameter control method, allowing the client to prove more obviously that their part met the stated specification.

Viewpoint developed the software and selected the NI hardware for the first unit. The client is now deploying copies of this system to multiple international manufacturing plants.

Benefits

- Able to prove meeting a particular product specification of interest

- Closed loop parameter control

- Data collection

- Configurable Alarms

- Emergency shutdown functionality

System Overview

The cRIO-based endurance tester provides closed loop control, data collection, and alarming with controlled and emergency shutdown functions. The operator can manually configure a test or load a saved configuration. After a manual operator check to make sure the setup is operating correctly, a successful test will run its full duration and stop on its own.

| SOFTWARE FUNCTIONS |

|---|

| Touch PC interface / GUI |

| Closed loop parameter control |

| Data collection |

| Controlled & emergency shutdown |

| Alarming |

| HARDWARE USED |

|---|

| NI CompactRIO |

| NI analog input cSeries module |

| NI analog output cSeries module |

| NI digital input cSeries module |

| NI digital output cSeries module |

| INTERFACES / PROTOCOLS |

|---|

| TCP |

Product Validation using LabVIEW RT & LabVIEW FPGA – Electromechanical Actuator Test Stand

Product Validation using LabVIEW RT & LabVIEW FPGA – An electromechanical test stand for an aerospace actuator

Automated testing reduces operator man hours and increases production throughput.

Client – A manufacturer of actuators in the mil-aero industry.

Challenge

New Product Introduction (in this case a new controller and new actuators) drove the need for a new aerospace electromechanical test stand.

Solution

New NI PXI-based electromechanical test equipment provided automated HIL testing, report generation, and SPC data generation. The sequencing of the test procedure, reporting, and verifiable results were managed with the StepWise test executive platform.

Benefits

- Automated testing reduces operator man hours and increases production throughput.

- Meets strict customer requirements regarding testing and data recording in a verifiable manner.

- Automated Test Report Generation.

- Collects data to support SPC (Statistical Process Control).

- Ability to interact with the internal state of the controller FPGA via the LVDS communication link.

System Overview

Viewpoint developed the software and selected NI data acquisition and control hardware for the test stand. There are several layers of software functionality.

| HOST LABVIEW SOFTWARE LAYER |

|---|

| Test sequencer |

| Test steps (e.g. Frequency Response, Step Response, Dynamic Stiffness, Fault Response, Power Consumption) |

| Test Report Generator |

| GUI |

| REAL-TIME (RT) LABVIEW SOFTWARE LAYER |

|---|

| Data acquisition |

| 1553 comms |

| Function generator |

| Error detection |

| ESTOP |

| LABVIEW FPGA SOFTWARE LAYER |

|---|

| Synch data from 3 sources (tester, UUT, external DAQ device) |

| Stream high-speed data to disk |

| Stream high-speed data to analog outputs for HIL test |

| Custom communication protocol used by UUT over LVDS lines |

| HARDWARE RECOMMENDED |

|---|

| NI PXIe |

| NI FlexRIO card with LVDS adapter module |

| Multiple NI R Series cards |

| High speed, high voltage, isolated analog input cards |

| INTERFACES / PROTOCOLS |

|---|

| MIL-STD 1553 bus |

| LVDS |

| Ethernet |

| Custom TCP/IP |

*- images are conceptual only, not actual

Creating an N-Up Tester to handle increased production volume demands

Creating an N-Up Tester to handle increased production volume demands

Enhanced throughput offers ROI payback period of less than 1 year

Client

Automotive Components Supplier / Manufacturer

Challenge

The company makes automotive components in very large volume, several part models each at more than 1 million per year.

The client’s primary concern was conserving floor space. They were completely out of spare manufacturing space.

Solution

Viewpoint created an N-up NI PXI-based Manufacturing Test System. In this case, N=6 because analysis showed that a 6-up electronic part tester allowed the test operator to cover the test time with the load/unload time.

At the high volumes needed, the client needed to parallelize as much as possible. The cost of 6 sets of test equipment and device sockets was less important than speed. Using the equation:

ProfitPerUnit x NumberAdditionalPartsPerYearAfterParallelizing > CostOfTestEquipment,

being able to completely parallelize made the number of extra units per year large enough that the payback time for completely duplicating the measurement instrumentation for each UUT socket was less than about 1 year.

Benefits

- Paid for itself in less than 1 year by the enhanced throughput.

- This approach consumed about 20% the floor space that would have been used for duplicating the test system 5 more times (for a total of 6 testers)

System Overview

Viewpoint developed an NI TestStand application that ran 6 instances of the test sequence independently of each other utilizing the duplicated PXI-based test equipment. The common parts of the overall master sequence were:

- Startup check for the entire test stand

- Shutdown of the entire test stand

- Archiving the test results into the database

Part handling was managed by a PLC and robot which delivered the parts from a tray into the UUT sockets. Digital bits were used for signaling the test sequence which parts were present in their sockets and ready to test.

| SOFTWARE FUNCTIONS |

|---|

| Test System GUI |

| Test sequencer |

| Startup checker |

| Test Results Archiver |

Increasing Test System Automation for Existing Tester to handle Production Volume Demand Increase

Increasing Test System Automation for Existing Tester to handle Production Volume Demand Increase

Reduced test time across several products by an average of ~25% and reduced time to create paperwork by ~3x

Client

Manufacturer of high-voltage power supplies

Challenge

The client already had an existing manufacturing test system in place. They wanted Viewpoint to enhance the tester due to an increase in production volume demand. Viewpoint reviewed the existing test system and noted 3 areas for improvement:

- Automation available in the measurement instruments – most of the test equipment was automatable, via some combination of serial, GPIB, or Ethernet interfaces. Furthermore, some equipment, such as an oscilloscope, had the ability to store and recall setup configurations. The test operators already used these configurations to decrease setup time for the next test step. Most test equipment did not have automated setup.

- Operator time spent on each test step – the client had been through a Lean assessment and had already done a good job of timing operations. However, we specifically noted that the operator was manually connecting to the test points and manually transcribing to paper the measurement results from instrument displays.

- Automating the connections – many types of product models were being tested at this test system. Connecting the test equipment to all sorts of products would require either 1) many types of test harnesses and connectors or 2) a redesign of the products to make test connections simpler and quicker.

Solution

The enhanced automated test system included automation of instrumentation interfaces, a test executive to run the test sequences, automated test report generation, and automated test data archiving for the electronic UUT.

Benefits

- Reduced total test time across several products by an average of ~25%.

- Time to create paperwork was reduced by ~2/3 due to automated data collection.

System Overview

The enhanced test system included the following updates:

- Test sequence automation

- Automated test report generation

- Automated test data archiving

- Automation of instrumentation interfaces

- Configurable automated test steps associated with each type of measurement instrument. The test operators would create a sequence of steps to setup each instrument and record the resulting measurement. The sequence of steps could be saved and recalled for each product to be tested, so the instruments could be used automatically.

- New programmable meter – integrated the new DMM meter with a programmable interface to replace the one that was not automatable.

- Foot switch integration – Since the connections to the test points were manual, a foot switch allowed the operator to take the measurement and advance to the next step.

The StepWise test executive platform managed the multiple test procedures created for the different products. StepWise also handled creation of HTML reports for every part tested.

| SOFTWARE FUNCTIONS |

|---|

| Test GUI |

| Test Sequencer |

| Report Generator |

| Test Data Archiving |

| Instrument interfaces |

How to select a LabVIEW consultant

Maybe you’re LabVIEW programmer quit or retired, or maybe you’ve got some internal capabilities but need some additional support because everyone’s too busy. From hourly rates to a range of skills, there are several factors to consider. We’ll help you weigh each one. See How to Select a LabView Consultant.

LabVIEW developers: local vs remote

Headquartered in Rochester NY, we help customers all over the U.S. See the Pros and Cons of a local vs remote supplier for LabVIEW-based test system development.

3,000+

LabVIEW solutions deliveredGreat for automated measurement & control: manufacturing test, product validation, machine control and condition monitoring.

700+

LabVIEW FPGA systems deliveredGreat for applications requiring seriously deterministic timing, reliable code execution, and multi-channel synchronized processing.

1,000+

LabVIEW RT systems deliveredThe combination of LabVIEW RT and the RTOS on which it runs allows for the creation of applications with bounded jitter and latency.

500+

cRIO-based systems deliveredCombining a cRIO controller with the multitude of C Series modules creates a functional real-time controller in a small footprint.

1,500+

PXI-based solutions deliveredBroad range of off-the-shelf expansion cards & processing horsepower make PXI a formidable choice for many automated test applications.