What to do with your Manufacturing Test Data after you collect it.

Collecting a bunch of data without having a plan for how to utilize it doesn’t help anyone.

Why it matters:

All that data you collected is very important for understanding,

- how your device is performing

- how under control your manufacturing is

- any inefficiencies in manufacturing

If you don’t have identifiers on the type of data being collected it could get mixed in with the data from unrelated tests. This makes it much more time consuming to analyze the data. You could also miss things in your data since you haven’t identified well.

Tips for what to do instead:

- Add a unique prefix when storing your data to make it easier to sort and analyze. For example, you may have two tests that record BERT values. If you name the test data BERT test for both it will be impossible to differentiate between the two. Instead you may want to add prefixes or unique identifiers.

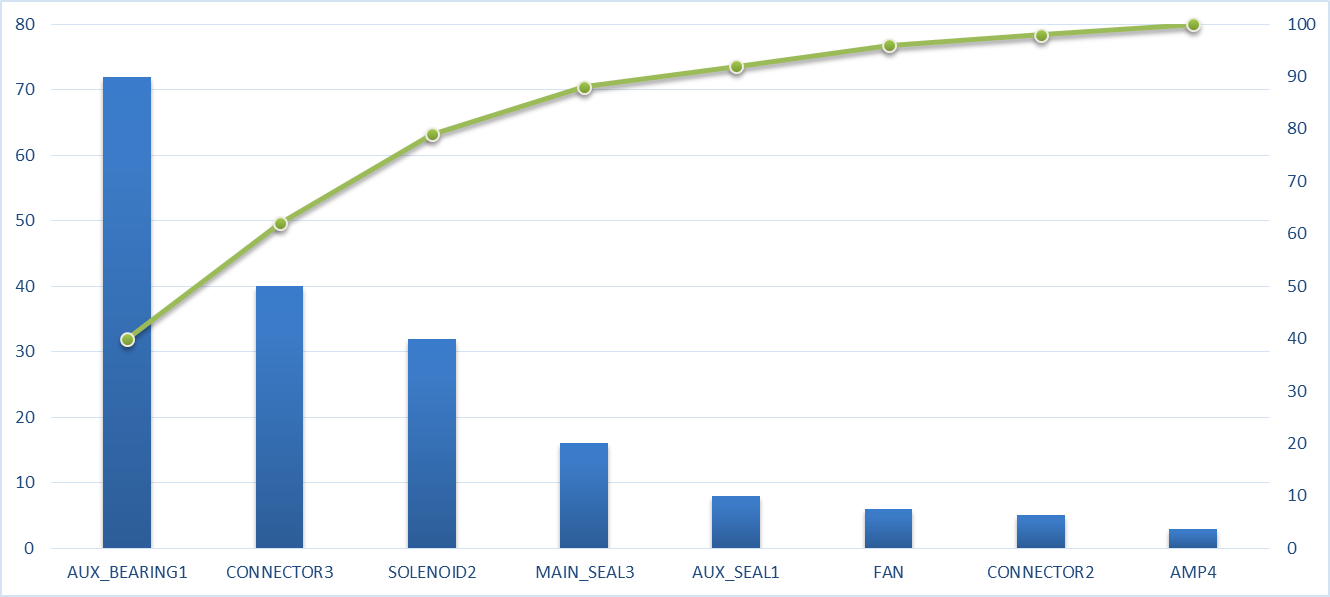

- Use the data to improve your manufacturing efficiency by running a pareto analysis to identify your most frequent failures. You may want to create a pivot table from your data.

- Check out this report on reducing production costs by integrating test and business systems and embracing electronic records.

Poll – Test engineering leaders: What would help you most? Vote and see how your peers voted!

We’ve often seen people put together test stations to collect data, but have no idea what to do with those test results. It’s important to think about what sort of information you want to derive from the data. Do you want to look at trends for power out on a unit, or missed or corrupt bits in gigabytes of digital data? Make sure you consider your data analysis goals before you finalize your test so that the data can be collected in a manner that facilitates the type of analysis you want to perform.

Not knowing what you are doing with your data after you collect it can cause multiple issues. If you don’t know what information you are targeting you may not construct your test in a way that collects that data. Determine the key metrics before you write the test to make sure that the information isn’t missed.

Organize your data in a scheme that makes it easy to retrieve later on. If you don’t have identifiers on the type of data being collected it could get mixed in with the data from unrelated tests. Using a common prefix when storing your data can help with this. For example, you may have two tests that record BERT values. If you name the test data BERT test for both it will be impossible to differentiate between the two. Instead you may want to add prefixes or unique identifiers. For example, 1.1.1 Uplink BERT = [measured BERT] and 2.1.1 Downlink BERT = [measured BERT].

If your goal is to improve manufacturing efficiency by identifying your most frequent failures, you may want to create a pareto chart from your data.

This charting can only be done well if you store the data in a way that is specific enough to identify the failures. For example, saying serial communications failure isn’t as useful as providing the specifics of the failure such as unable to communicate due to no response, frame error, incorrect response, response timeout, etc. Having this level of resolution can really help when trying to slay these systematic issues with your test.

Using your data to drive manufacturing efficiency is important. We’ve worked with customers to reduce their production costs as much as 30% across multiple product lines. Check out this report for more information on how we did this.

Next Steps

Want help organizing your manufacturing test data?

If you’re deep into learning mode, check these out:

- Making Good Measurements for Automated Test

- 9 Considerations Before you Outsource your Custom Test Equipment Development

- Test Automation Best Practices – for automated hardware testing

- Product Testing Methods – for industrial hardware products

- Webinar: How Aerospace and Defense Manufacturers Can Make the Assembly and Test Process a Competitive Advantage

- An argument gainst Universal Test Equipment

- How to prepare for when your test team starts to retire

- Practical manufacturing test and assembly improvements with I4.0 digitalization

- What to do with your manufacturing test data after you collect it

- 5 Keys to Upgrading Obsolete Manufacturing Test Systems

- Reduce Manufacturing Costs Report

- Improving Manufacturing Test Stations – Test Systems as Lean Manufacturing Enablers To Reduce Errors & Waste