Automated Test Systems for Automated Hardware Test

Who, what, where, when, why, how

Questions we’ll answer:

- What is an automated test system?

- Why/when are they needed?

- How are they used?

- Where are they used?

- Who uses them?

What an automated test system is

An automated test system is a combination of hardware and software that automates the hardware testing process for the product being tested. The test system could be for validating the product during the design phase, or for verifying the product during manufacturing. There are various levels of automation implemented based on factors relating to (1) production volume, (2) safety, and (3) product cost.

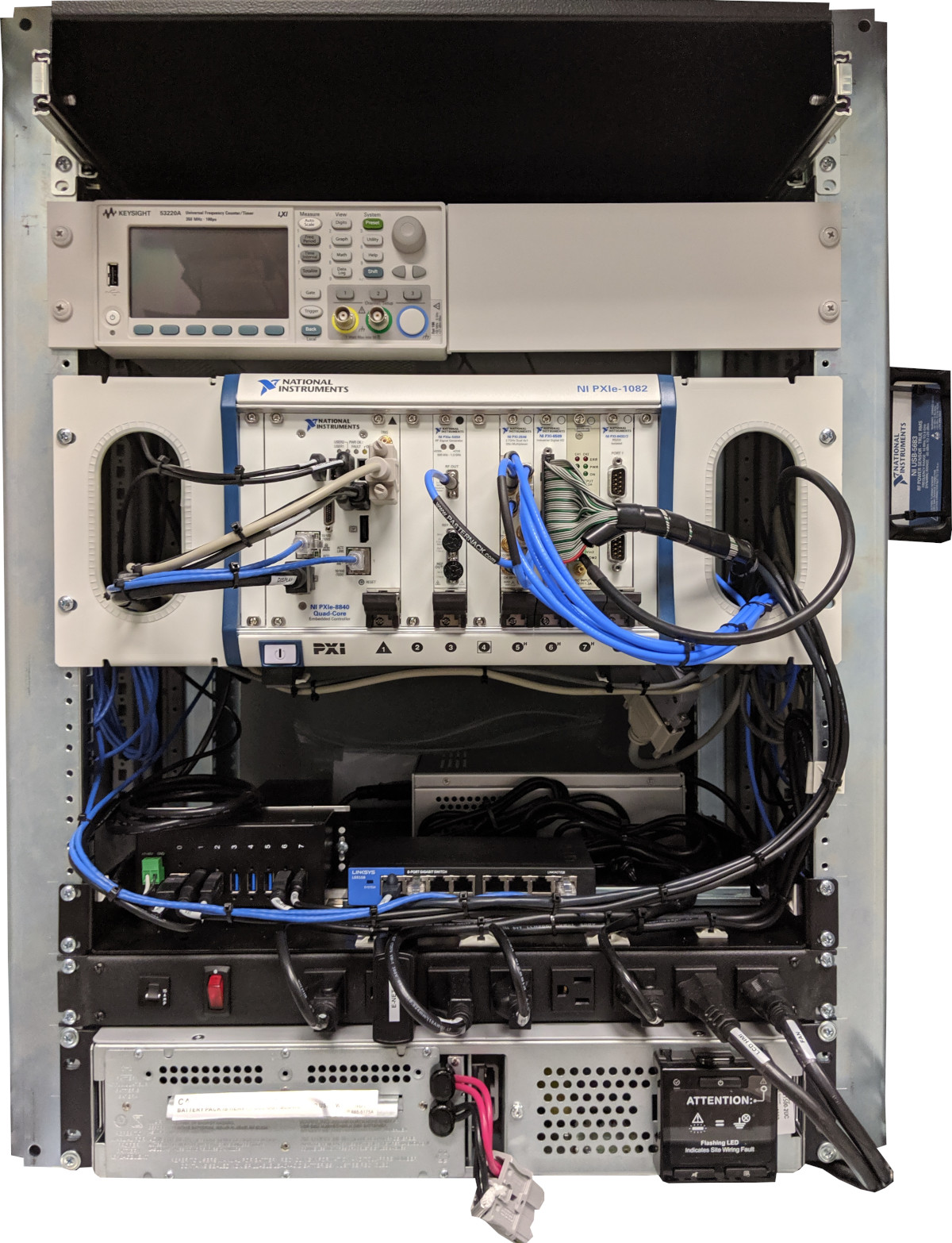

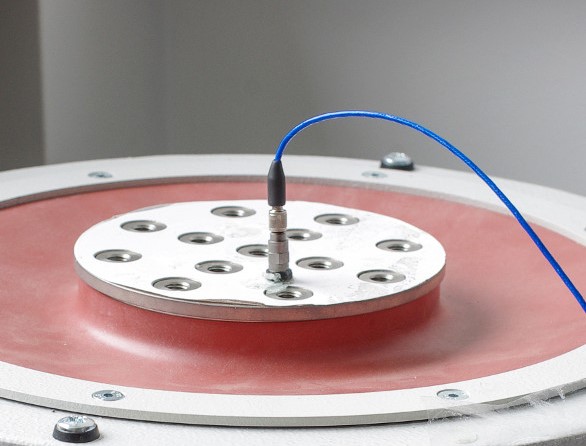

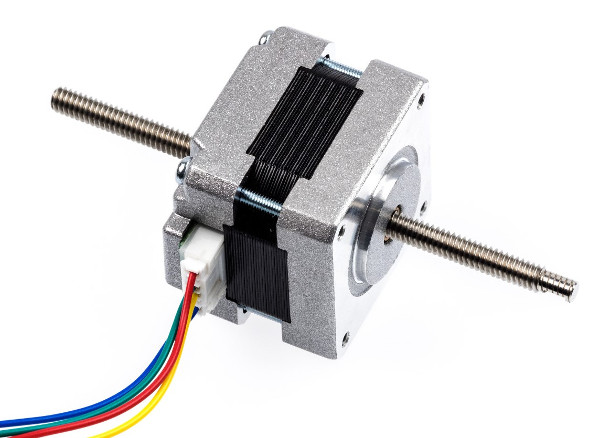

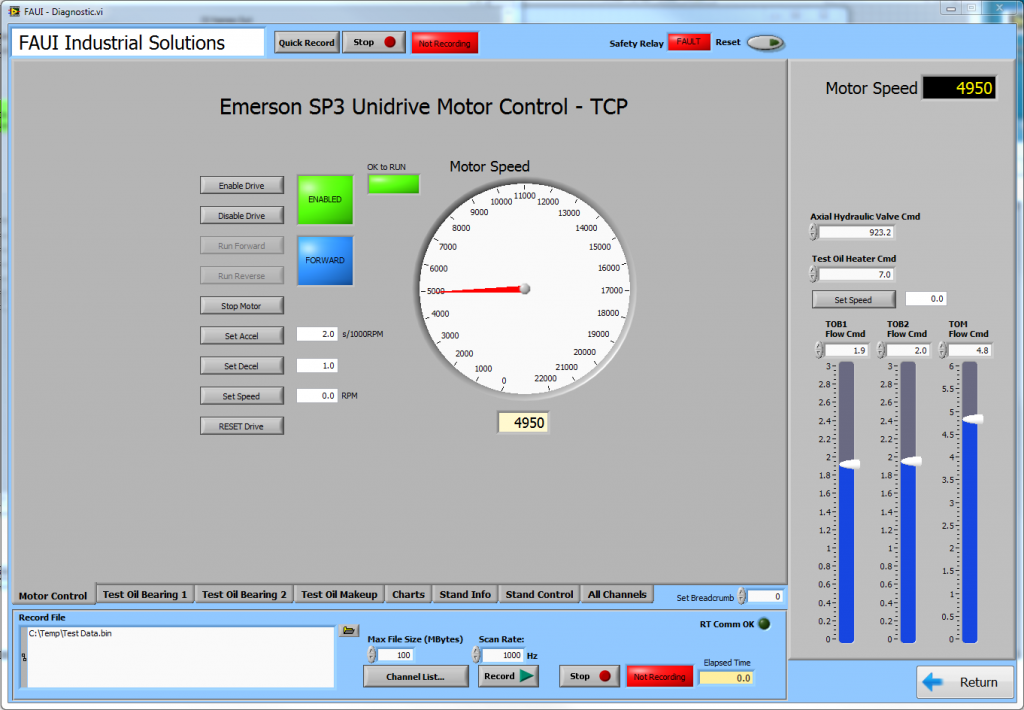

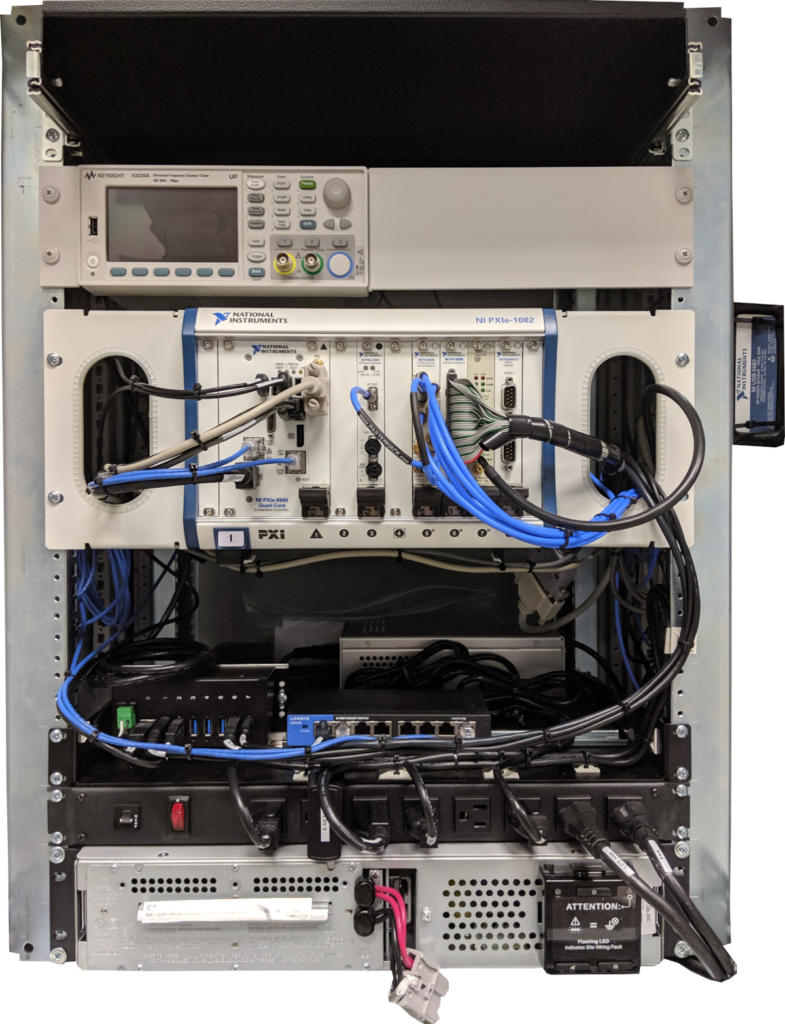

With a picture still being worth a thousand words, here are a few examples of automated test systems:

An automated test system usually consists of the following core components:

The core components are often augmented by various additional components, such as:

- Test fixture

- Benchtop instruments

- Power supplies

- Test rack / enclosure

- Connecting cables

- Standalone controllers

- Computer

- IT infrastructure (e.g., database, storage)

- Integration with various business systems (e.g., historian, manufacturing execution system, enterprise resource planning software)

When/why automated test systems exist

Test systems for automated hardware testing generally exist for one or more of the following reasons:

- Reduce labor costs

- Reduce human error

- Improve personnel safety

- Reduce the probability of damaging the product during validation

How automated test systems are used

Manual testing requires a technician/operator to probe around the UUT (Unit Under Test) and take various measurements, make calculations, and record results. Automated test systems are used to reduce or eliminate human involvement in the hardware testing process. Automation can consist of one or more of these types:

- Part placement into and out of a test fixture

- Measurements – temperatures, pressures, vibration, voltage, current, load, force, proximity, location, etc.

- Stimulation – waveforms, pulses, actuation, power, etc.

- Analysis –calculations, limit checking, frequency domain analysis, filtering, etc.

- Test report generation – pass/fail, statistical data, raw waveforms, etc.

- Test data archive

Where automated test systems are used

Automated test systems are used in all sorts of manufacturing facilities (both in manufacturing plants & R&D labs), in industries such as:

- Aerospace

- Automotive

- Rail

- Defense

- Medical device

- Industrial component Manufacturing

- Semiconductor

- Energy/power.

Who automated test systems are used by

- Test engineers, both on the design validation side and the manufacturing test side.

- Manufacturing operators/technicians/assemblers.

Off-the-shelf vs custom automated test systems/equipment

Anyone would want an out-of-the-box solution whenever possible. For some applications (like any testing meant to verify that a standard is being met, such as from SAE, IEEE, API, ASTM, UL, and so on), the commonality is there to justify the creation of a ready-to-configure tester.

In many other cases, the product being tested is different enough from previous products and competing products, or does not have to meet an operational standard, that a custom (or, more commonly, a semi-custom) automated test system has to be developed for that specific UUT. When that’s the case, usually many of the hardware components (except maybe the fixture that attaches the UUT to the tester) are available off-the-shelf. There are also often pieces of software that can be re-used. These pieces of hardware and software then need to be integrated together into an automated test system.

How custom automated test systems are developed

Automated test systems are developed by:

- Understanding the requirements for proper UUT operation

- Selecting, integrating and developing the right pieces of test hardware

- Integrating and developing various pieces of test software

Hardware components to be selected and integrated

- Sensors (with corresponding signal conditioning, which may not be built in) – temperature, pressure, accelerometer, strain, etc.

- Actuators – motion controllers, motors, air cylinder clamps, hydraulic cylinders, etc.

- Benchtop instruments – network analyzer, power meter, spectrum analyzer, oscilloscope, etc.

- Measurement hardware – we like National Instruments hardware as the core measurement hardware (see our article on Which NI Platform is Right for Your Automated Test Needs? cRIO, PXI, cDAQ, sbRIO?) , but there are certainly other measurement hardware options out there as well: for example PXI Products | Keysight and Data Acquisition – DAQ | Keysight

- Power supplies – to power up the UUT

- Test rack / enclosure

Hardware components that are often developed on an as-needed basis:

- Cabling and/or harnessing

- Test Fixture

Common test development software used to develop custom test software

- LabVIEW – the de facto test software development environment

- C# – a good alternative when you don’t have LabVIEW experience or want to include extensive database and web support

- Python – the newcomer, but seems to be gaining traction

Next steps

If you need a custom automated test system, you can reach out here. If you need some help with your LabVIEW, see here. If you’re interested in other automated test resources, check out our Automated Test Systems – Resources page.

A few other resources that may be of interest:

- Commissioning Custom Test Equipment – process, pre-commissioning checklist, and gotchas

- Hardware Product Testing Strategy – for complex or mission-critical parts & systems

- Have a Question? Ask a LabVIEW Expert

- Automated Test System Cost Calculator

- LabVIEW Test Automation – Custom Automated Test System Buyers Guide

- Test Systems as Lean Manufacturing Enablers To Reduce Errors & Waste

- How to Improve a Manual Testing Process