Hidden Factory of Waste

Merging business systems with test systems to reduce manufacturing overhead and waste

What You Care About

Your manufacturing has too much overhead, rework, and transactional waste and you’d like to streamline your production processes. Your indirect costs are just too high relative to your direct costs.

Your plant likely already has manual or automated test stations but you’d like to link the business database with the test systems in order to share data for such things as:

- WIP status – automatically retrieve the status of your partially assembled inventory

- Order information (e.g., version of part being assembled) – make sure your operators are building the proper part for the present customer order

- Predominant reject modes – assess the large issues and fix them first

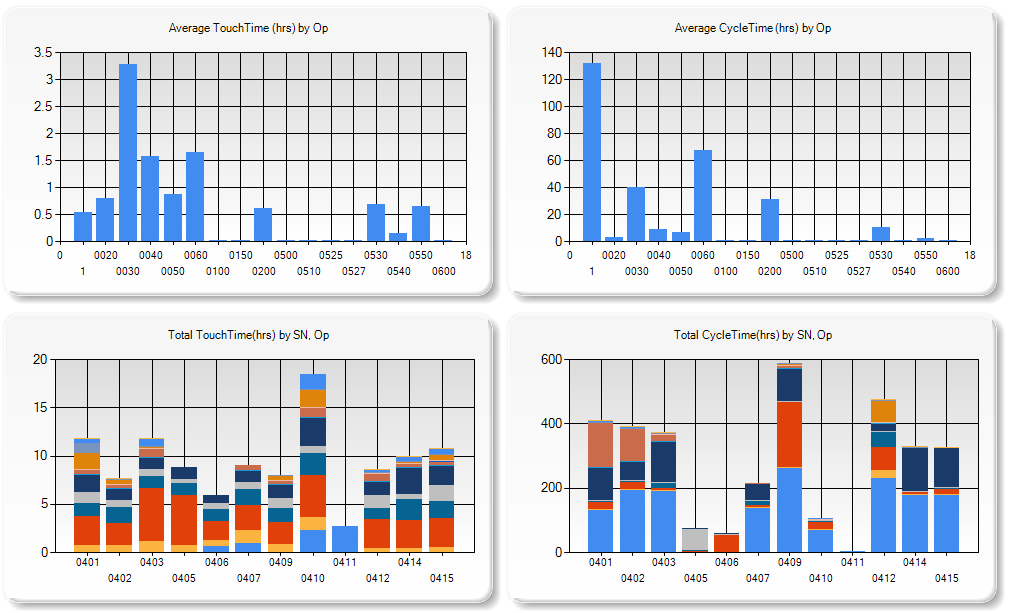

- Step-by-step assembly times – improve the assembly process by locating the bottlenecks

You’ve always thought that test systems could combine a pile of data with your business databases to help you locate that hidden factory of waste.

How We’ve Helped Our Clients

A test system that shares data with business systems can help identify sources of waste in manufacturing. Some areas in which we’ve helped our clients be successful when combining test and business data are:

- Automated collection of raw test results, connected those results with the part serial number, performed statistical analyses to identify the most frequent reject modes, and automated generation of various failure mode reports

- Automated the retrieval of work instructions based on part type so the operator would use the correct and most recent assembly procedures

- Pushed part status information from each test station into the business database and created a report so that WIP status was available for the parts on the factory floor

- Measured performance and quality at each test station to help with Overall Equipment Effectiveness (OEE) calculations for the assembly steps and part production

Some of our clients have seen a 30% decrease in manufacturing cost on average across all their production lines due to the removal of transactional costs and reduced rejects. The hidden factory is revealed by combining these datasets.