6 Tips to help with noisy signals causing inaccurate test results

There’s so many things to keep in mind when developing or utilizing test systems. Some things are more obvious than others, but all of them can create problems. One of the more painful problems that can occur is due to noisy signals causing inaccurate test results. There are many complexities related to this topic, so you really want an expert involved. Here are a few tips to help with this challenge:

| 6 TIPS TO HELP WITH NOISY SIGNALS. |

|---|

| Keep signal wires away from other wires that could induce noise on the line, such as AC power lines. |

| Use shielded, twisted pair wiring for critical signals. |

| Make sure all your physical wire terminations are done well. |

| Check for and fix any loose wires or connectors. |

| Look for cold solder joints, bad splices, and incorrectly crimped connectors. |

| Read your sensor datasheet or manual to see if signal conditioning is needed to amplify, transform, and/or filter your signal for your measurement device. |

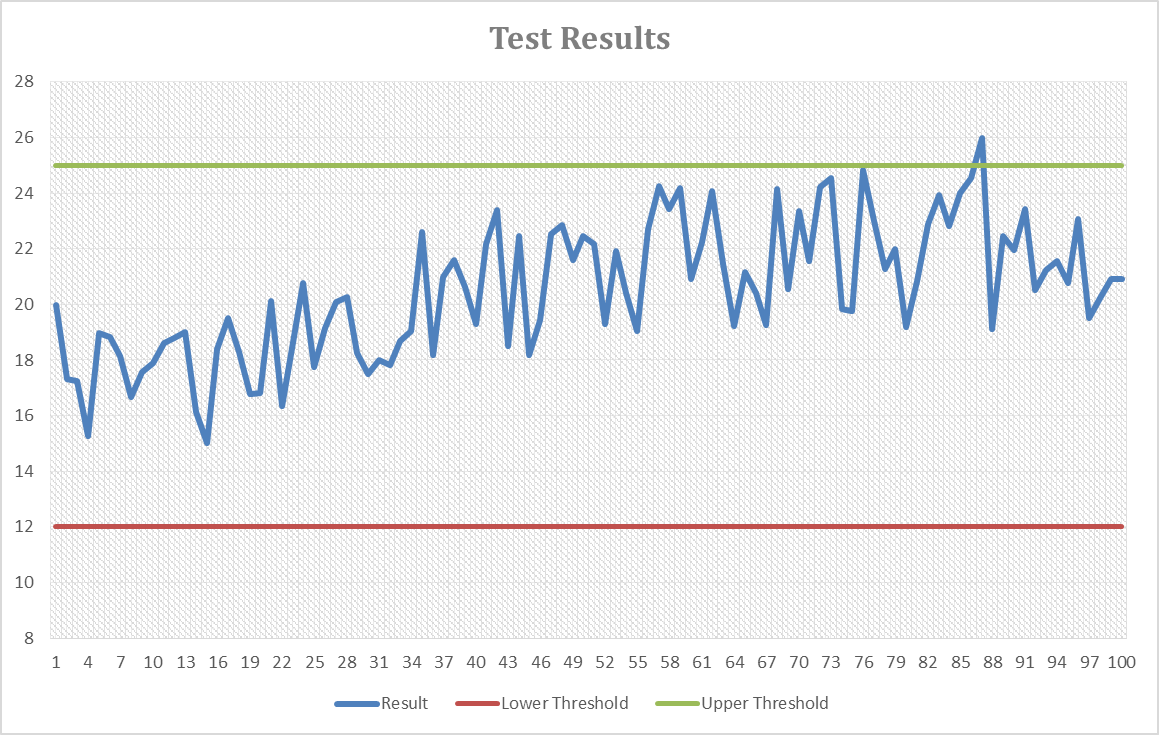

It’s quite common that test systems won’t work right due to noisy signals, incorrect voltage levels, or lack of signal conditioning. These noisy signals can cause inconsistent results in your manufacturing test, effecting yield or wasting time retesting or debugging failures.

Make sure all your physical wire terminations are done well. There shouldn’t be any loose wires or connectors. A lot of times physically inspecting each connector will quickly resolve signal issues. First look to make sure the connection appears to be ok. The most obvious thing to look for are wires not connected to anything. Inspect the crimp and make sure the area of compressed metal looks uniform with the wire inserted far enough into the connector to get a solid physical connection. Then physically wiggle the connector and wire to make sure that the connector does not come off, or the wire comes out of the connector. You can also observe your signals while doing this to see if it makes any changes in the signal. If it does, then you probably need to redo that connection.

You can avoid noisy signal issues by making sure that you have well routed signals with signal conditioning if needed. Keep signal wires away from other wires that could induce noise on the line. For example if you are running low voltage signals near AC power lines you could see that AC power in your sensor data. Shielded and twisted pair wiring can help. Make sure to connect the shield to a solid signal ground. Avoid ground loops as well since they can cause inaccurate readings. Make sure that the path to ground is as short as possible with as little path resistance as possible. Ground loops can also be avoided by use of isolation transformers, optoisolators, or signal conditioning.

Read your sensor datasheet or manual to see if signal conditioning is needed to amplify, transform, and/or filter your signal for your measurement device. If it is not obvious from the manual if there should be signal conditioning, contact the manufacturer.

Noisy signals causing inaccurate test results is just one of the gotchas you might come across when developing or using a manufacturing test station. Check out others in this white paper: Customer Manufacturing Test Stations – Top 6 Gotchas. If your noisy signals are causing inaccurate test results and you’d like some help diagnosing the problem, reach out to us here.