Automated Measurement System – Verifying Flow Rate Performance in a Medical Device

Assessing quality and managing traceability of a medical device

Automation increases throughput by testing multiple units independently

Client

Worldwide supplier of products for surgery

Challenge

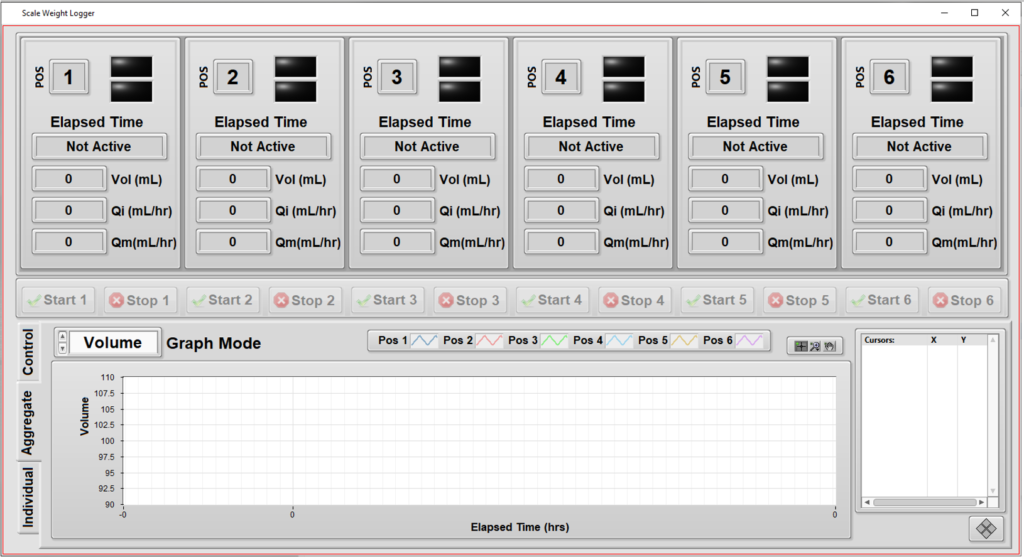

Our client wanted to perform detailed quality checks on the performance of some of their fluid dispensing products. These products dispense fluid over long periods of time (hours) so rigorous testing of each unit in production would take too long. But, being medical devices, these products need to follow ISO 28620 standards and FDA 21 CFR Part 820 regulations, so a rigorous test process is helpful to fulfill these needs. The automated test system below is part of that overall fulfilment.

The client came to Viewpoint with the following high-level desires for a system to test the product:

- Support independent configuration and testing for up to 6 units.

- Simplify overall test setup by copying the configuration from one unit to another.

- Handle different volume amounts supported by assorted models.

- Measure from each unit the weight of fluid dispensed as a function of time. (Weight was converted to volume using the fluid density.)

- Compute the “instantaneous” flow rate (volume vs time) as the test progresses.

- Keep track of the calibration status of the weight scales at each of the 6 positions in the test system.

- Enable some measurements to be excluded at the start and end of the run for calculations of average flow rate.

- Provide graphs and metrics of results to enable faster review of the data during the test.

- Add ability to comment on each unit while testing is in progress, and after, and track these for compliance.

- Print (PDF) a report on each unit’s results along with its identifying info, such as subcomponent lot numbers, the test datetime stamp, and the operator’s ID.

Solution

The client had an initial version of the testing application which they developed for testing their various initial design iterations. Viewpoint enhanced this existing application with the features listed above. The motivations for this enhancement were to:

- Automate testing of the initial production units more thoroughly than the existing application allowed.

- Enhance the user experience for easier testing.

A major aspect of the user experience was to support testing of multiple units independently from each other so that unit testing on one device could start/stop while other devices were installed in (or removed from) the tester without interrupting tests on other units.

- This need was especially important since some models might take twice as long to test as other models or the setup of one unit might need additional adjustments before starting. This meant that starting and stopping all at the same time could reduce utilization of the tester, and it made sense to have independent and parallel operation.

- Furthermore, with parallel testing, the tester was not constrained to having a full set of units to begin testing operation, since the tester could run with only 1 unit installed.

The other major enhancements focused on the user experience by offering real-time data of a particular unit’s testing, as well as real-time graphs to show progress. These graphs were useful because the operator could clearly see when a unit was not performing as expected and the test for that unit could be aborted without affecting testing on the other units.

Since this testing needs to follow the requirements in the ISO 28620 standard and 21 CFR Part 820, it was important for the application to be aware of the calibration status of each of the 6 weight scales, one for each position in the test system.

Benefits

The main goal of this project was to augment the test operator’s ability to set up the testing of products while providing real-time visual feedback to the operator about the testing status.

Some of the benefits of this automated test system were:

- The test automation provided consistency resulting from the software-enforced test process.

- Test status via the visual feedback helped increase the efficiency of the operator.

- Enhance the user experience for easier testing.

System Overview

The application was developed in LabVIEW and measurements were made via RS-232 communications to each of the 6 weight scales. Once a unit was installed in the tester and the operator started the test on that unit, the application:

- tared that unit’s scale,

- started the flow,

- and collected weight measurements frequently to build a curve of “instantaneous” flow versus time.

These “instantaneous” flow numbers were used to compute statistics such as maximum flow and average flow over the course of the entire test run.

Some of the primary functionality of this system includes:

- Independent tests: testing a specific unit doesn’t interfere with testing of others.

- Graphs of flow rate during the test execution: visualize the unit’s performance during the hours-long test time, not just at the end.

- Calibration check: the next calibration date of each of the weight scales are maintained in a configuration file, so the operator can check that the test system is ready to run a test at a particular position.

- Different volumes: since each unit is tested independently, the system can handle different volumes for each position in the tester.

- Enhanced commenting: operators can enter comments about each unit (or all of them) and have these comments archived for compliance purposes.

| SOFTWARE FUNCTIONS |

|---|

| Logging of weight versus time for up to 6 test positions via RS-232 communications to scales. |

| Manage the configuration and commenting of the test. |

| Save, recall, and copy configuration information to ease the operator’s setup effort and time. |

| Display graphically the curves of flow versus time while the test progresses. |

| Compute statistics on the flow after test completion. |

| HARDWARE USED |

|---|

| Multiport ethernet to RS-232 serial communications. |