Industrial Embedded – Using a cRIO for Rapid proof-of-concept Prototyping

FPGA-based motor control & RT-based loop control.

The NI cRIO platform allowed for rapid development/test cycles. There was as little as ~1.5 hours between a software change and a test.

Challenge

This was a rapid proof-of-concept prototyping effort to quickly determine feasibility of auto-pilot flight.

Solution

The cRIO-based controller was able to allow the helicopter to auto-pilot routed waypoints.

Benefits

The NI cRIO platform allowed for rapid development/test cycles. There was as little as ~an hour and a half time between a software change and flight test. Code updates could be flight tested in the morning, updated over lunch, tested again in the afternoon, updated one more time at night, and flown again the next morning. This allowed for rapid development of control laws.

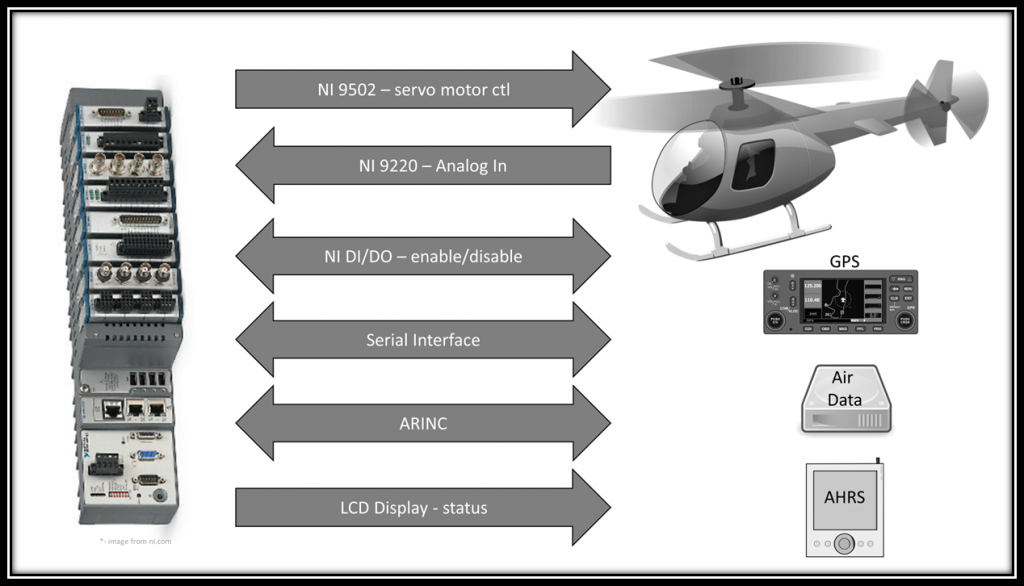

System Overview

The core system functionality consists of:

- resolver-based BLDC motor control

- position loop control

- vehicle dynamics control

- and flight logging.

Vehicle dynamics control and position control lived on the RT processor, while motor control and critical high-speed processing lived on the FPGA.