Industrial Embedded Monitoring & Control of Manufacturing Equipment

Adding Closed-loop Precision Control to Manufacturing Process with multiple international plant deployments

Client – Quantum Engineered Products Inc.

Challenge

Quantum produces manufacturing machine components that are used in the glass bottle forming process. Specifically, they supply plunger mechanisms that are used in the initial blank side formation of the glass bottle.

The engineers at Quantum recognized that they had an opportunity to improve the bottle formation process by adding position sensing to their plunger mechanisms. The ability to sense and record plunger positions would enable machine operators to monitor the travel of the Quantum plunger into the molten glass gob within the blank side mold, identify and diagnose potential hardware problems, and provide real-time feedback that could be used to better control the process.

Quantum needed a partner to implement real-time control and monitoring of the bottle forming process and selected Viewpoint for the task.

Solution

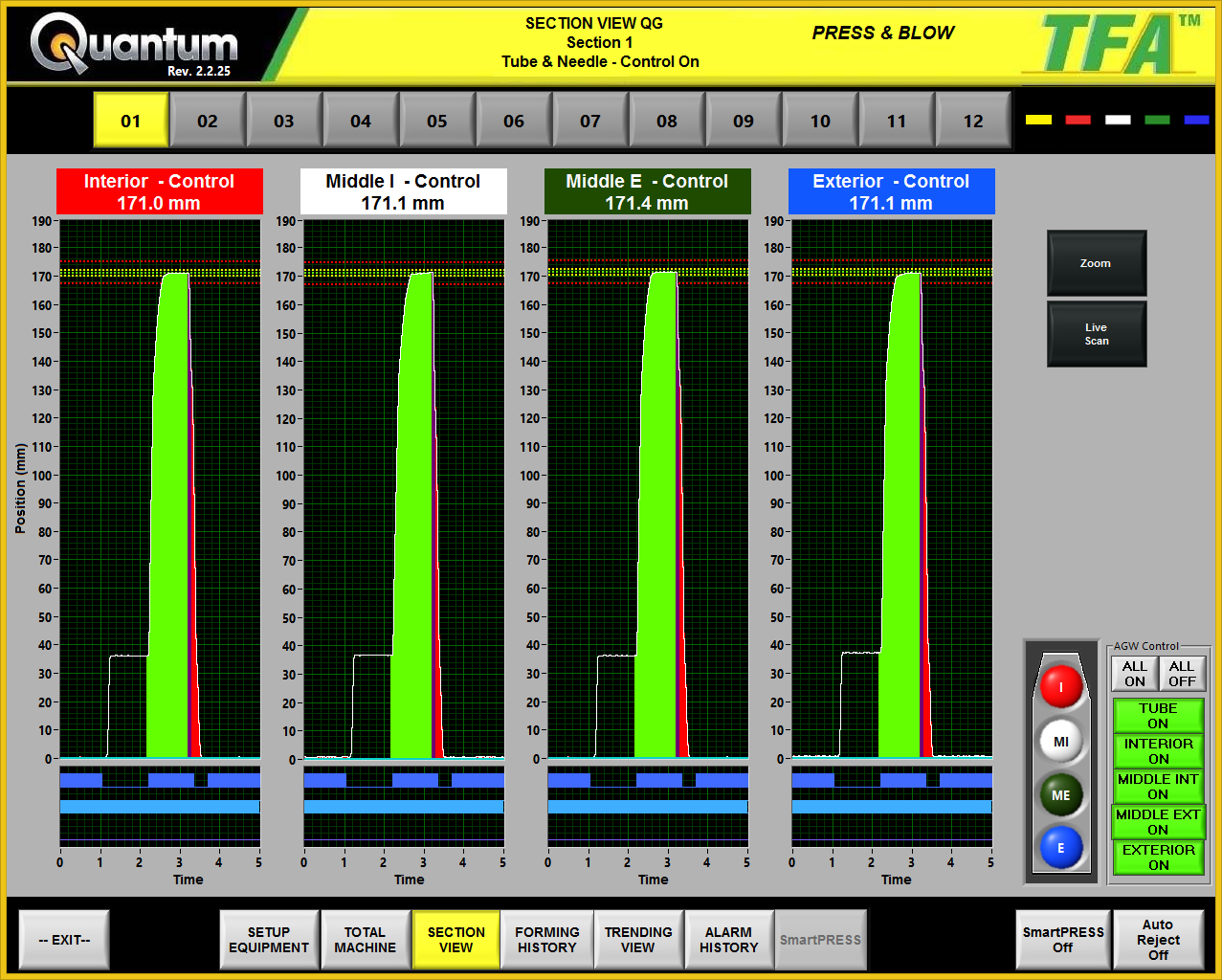

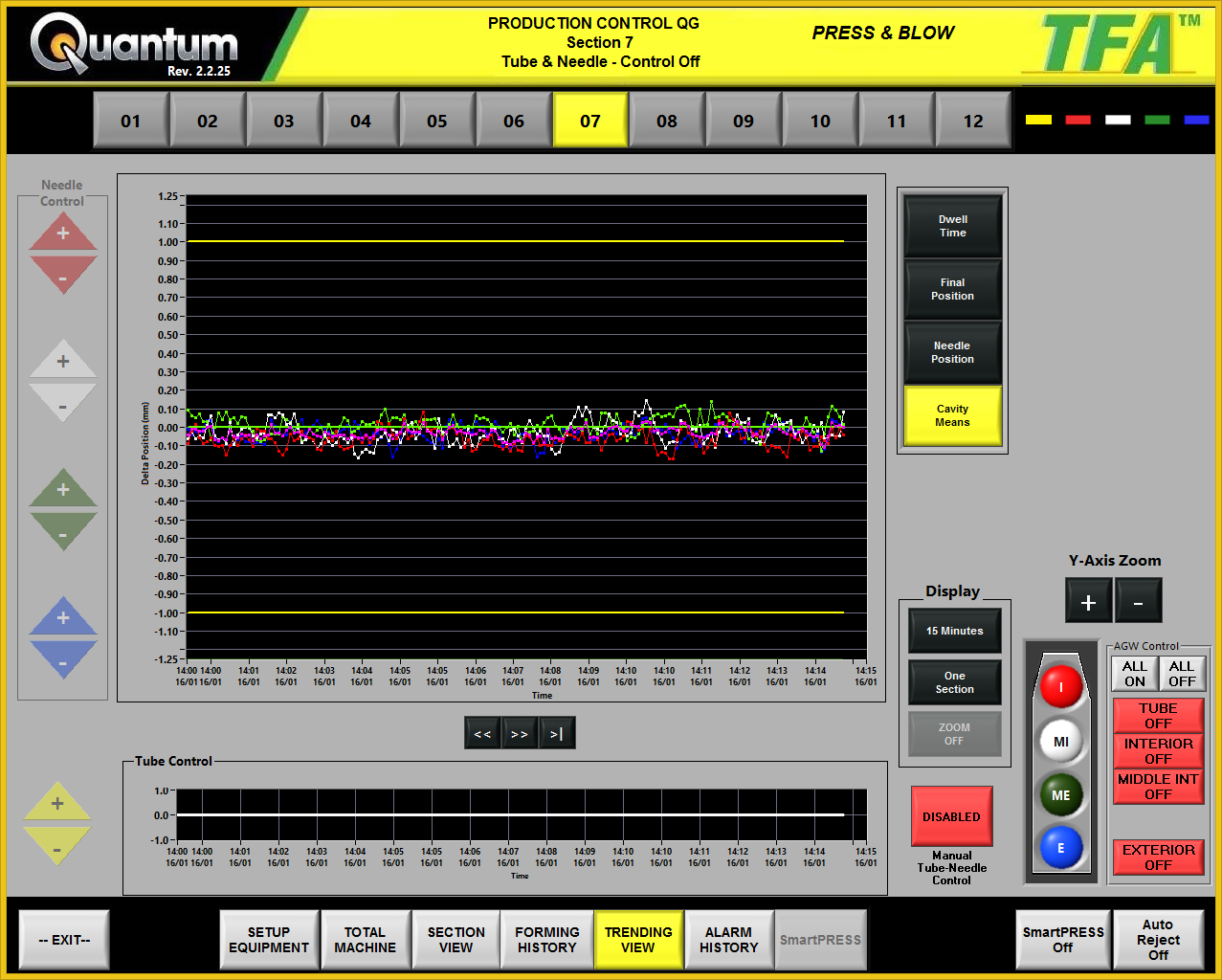

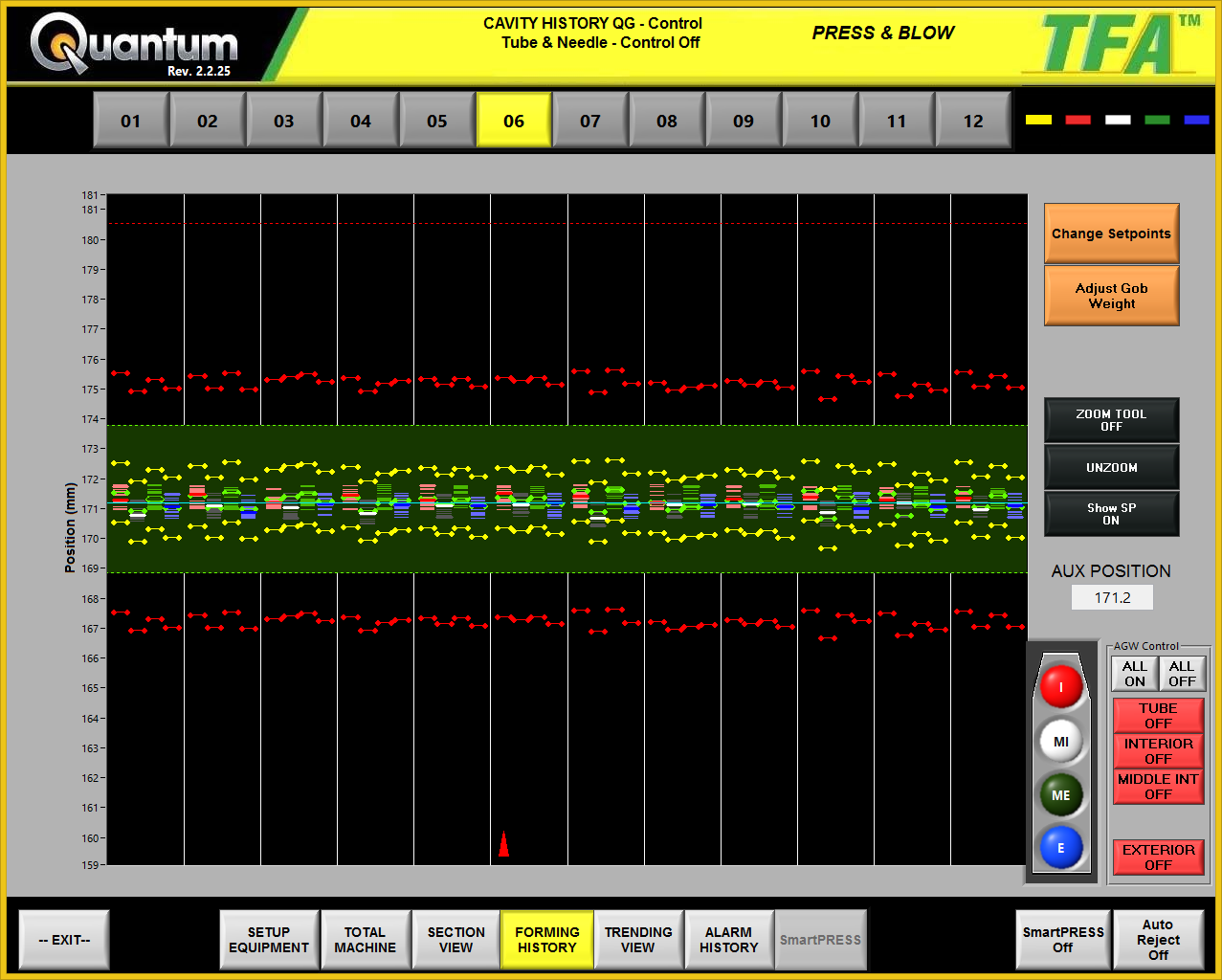

Viewpoint developed custom monitoring and control software that runs on off-the-shelf hardware. The software developed for Quantum is called TFA™ (Total Forming Analysis). The TFA™ software is a process monitor and control system for the hot side of the bottle forming process.

The software takes position information from the plungers Quantum supplies to the factories to show the travel of the tube during the forming process. The software measures key aspects of the plunger position profile such as initial plunger load position, final position, and dwell time at the final position. When these measurements are found to be out of tolerance, the software communicates with the machine auto-reject system to ensure that bad bottles are removed from the system.

Moreover, the final plunger position is used as feedback to do closed loop control of the glass gob weight, controlling glass feeder tube height and/or needle heights to change the glass gob weight. This allows for precise control of container weight, making the most efficient use of raw materials while ensuring container quality.

To accommodate multiple end-customer-driven hardware configurations, the off-the-shelf hardware selected was based on the National Instruments CompactRIO family of chassis to enable configuration of various input/output signal requirements.

For the end result, check out one of the machines running TFA™ in action:

Benefits

Hardware Customization Flexibility – every one of Quantum’s customers wants something either a little or a lot different with their particular instance of the system. Using modular hardware allowed for swapping of I/O hardware.

Quick Response to Software Feature Requests – Quantum and Viewpoint were in constant communication to be able to implement new features and tweaks on fairly short notice (generally within a couple of weeks).

On-Site Support – Viewpoint engineers travel to Quantum’s customer sites with them as a team upon request.

System Overview

The embedded process monitoring and control system consists of custom process monitoring and control software that runs on off-the-shelf hardware.

| NOMINAL HARDWARE |

|---|

| NI 9148 Ethernet expansion chassis |

| NI 9201 module for AI |

| NI 9425 module for DI |

| NI 9476 module for DO |

| SOFTWARE FUNCTIONS |

|---|

| Data Acquisition and Processing |

| Waveform Calculations (eg. final position and dwell time) |

| Final Position control loop |

| Real-time per cavity plunger position graphs |

| Process trend graphs |

| Forming history graphs, showing a packet of the last forty final positions per cavity |

| Limits definition screens |

| System health summary, fault monitoring and auto-reject configuration |

| Job configuration |

| Plunger sensor calibration |

| COMMUNICATION INTERFACES |

|---|

| Gb Ethernet communication with the DAQ devices (NI 9148 chassis) |

| TCP/IP Modbus communication with Schneider Electric motors for feeder tube and/or needle control |

TFA™ is a registered trademark of Quantum Engineered Products, Inc.